Installation, Pad mounting, Arm fabrication – Controlled Products Systems Group BG7705011 User Manual

Page 6

6

I N S T A L L A T I O N

PAD MOUNTING

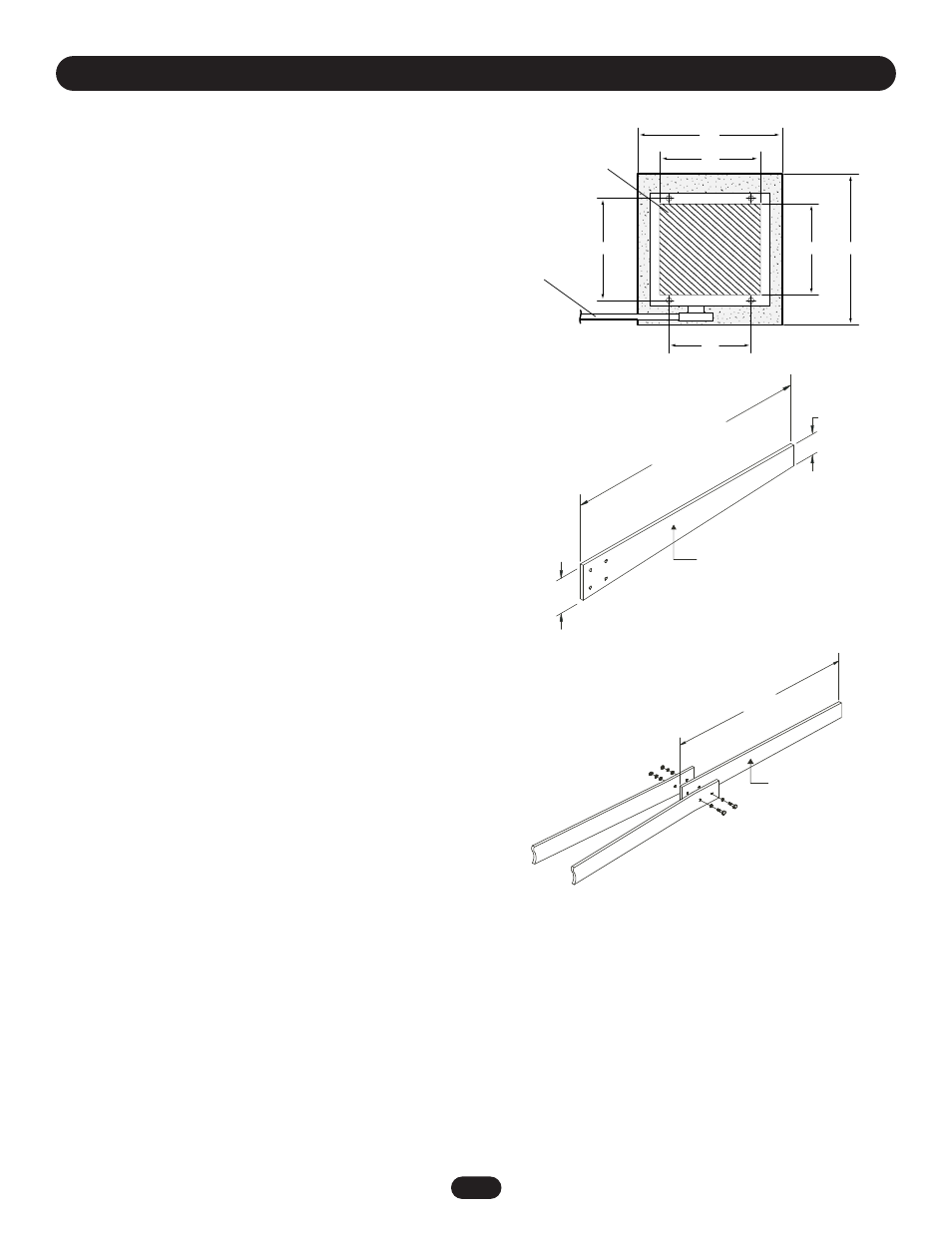

1. Layout the concrete pad (Figure 2). Be sure to locate electrical

conduit inside the hatched 14" x 13" area.

2. Excavate required area for pad and conduit. Pad depth should

be below the frost line or as required by local codes.

3. Pour concrete pad. Concrete pad should be level and above

the ground line.

4. Allow the concrete to set at least two days before installing

operator.

5. Secure operator with four concrete anchors (not provided).

ARM FABRICATION

MODEL BG770 (SINGLE ARM)

If you are making the arm yourself, refer to Figure 3 and its

suggestions for the single arm design.

1. Drill four 1/2" diameter holes using the arm clamp as a

template. Tapering the wood as shown helps reduce the weight

and allows you to reduce any warping common with long

lengths of lumber.

2. Finish arm with exterior grade paint and stripe with paint or

adhesive backed tape as required.

MODEL BG790 (WISHBONE ARM)

A 24' wishbone arm is provided as standard with every BG790

gate. If a shorter arm is desired, the extension may be shortened

(Figure 4). The maximum arm extension is 8' for a total arm

length of 24'.

1. Cut to desired length.

2. Finish with an exterior grade paint and stripe with paint or

adhesive backed tape as required.

Conduit Entry Area

Arm

20"

14"

12"

13"

22"

14-1/2"

Figure 2

Length as needed

up to 12'

5-12"

Material:

6: x 1" Pine or Redwood

3'

Arm

Extension

Length up to 8'

Material:

4: x 1" Pine or Redwood

Figure 3

Figure 4