Controlled Products Systems Group 9150-080 User Manual

High voltage connection, Automatic limits chain adjustment, Circuit board settings

4910

4910

RE

VERS

E

SENS

ITIV

ITY

RE

VE

RS

E

LOOP

EXIT

LOOP

KEY

SWITCH

DO

ORK

ING

460

2-0

10

SW1

SW2

OPE

N

TIME

R

W

ARNI

NG

MO

VIN

G G

ATE

CA

N C

AU

SE

Ope

rate

ga

te on

ly w

he

n ga

te a

rea

is

in

sig

ht

and

fre

e o

f pe

ople

and

ob

str

uction

s.

Do

no

t allo

w c

hildr

en

to

pla

y in

gate

are

a

or

ope

rate

ga

te.

Do

no

t sta

nd

in

gate

pa

th

or w

alk

thr

ou

gh

path

wh

ile

ga

te is

m

oving

.

Rea

d ow

ne

r’s m

anua

l and

sa

fety

ins

truc

tion

s.

SE

RIO

US

IN

JU

RY

OR

DE

ATH

CLA

SS

CE

RT

IFIE

D T

O

CAN

/CS

A C2

2.2

NO

. 2

47

CO

NF

OR

MS

TO

AN

SI/U

L-3

25

VEH

ICU

LA

R G

ATE

OP

ER

AT

OR

HP

53382

MO

DE

L

SER

IAL

VO

LT

S

PH

ASE

AMPS

60 H

z

MA

X

GA

TE L

OAD

Doo

rK

ing

, In

c.,

Ing

lew

ood

, C

A

ON

ON

RE

VE

RS

E

SE

NS

ITI

VI

TY

RE

VE

RS

E

LOO

P

EXI

T

LOO

P

KE

Y S

W

ITC

H

DO

OR

KI

NG

46

02-0

10

SW

1

SW

2

OPE

N

TIME

R

NC

1

2

3

4

5

NO

2.5”

Concrete Pad

Center

14.5”

Conduit Area

Electronic Box

8.5”

Hot Hot

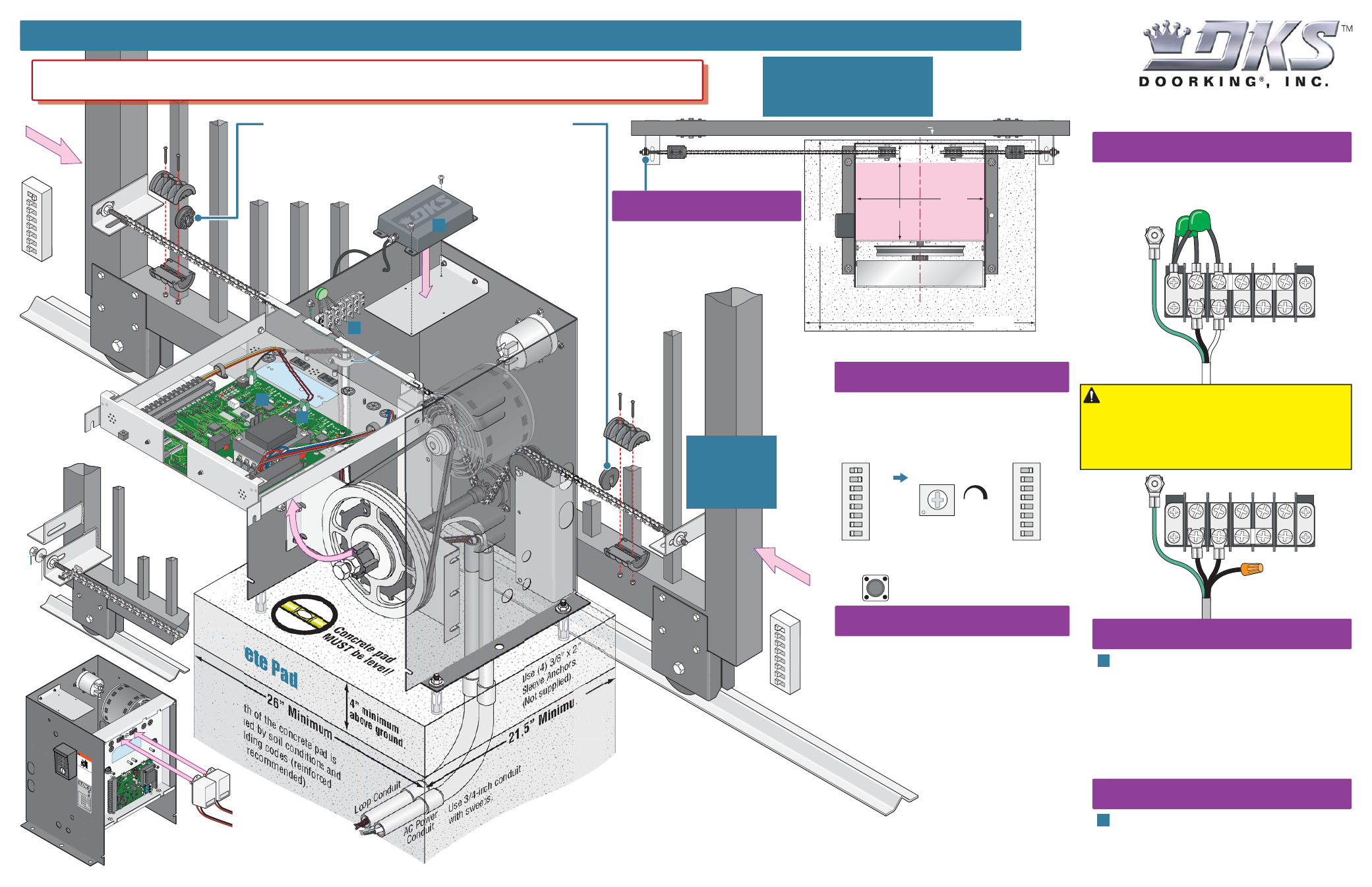

QUICKSTART “BASIC” GUIDELINES FOR MODEL 9150 - FRONT INSTALLATION MOUNTED ON A CONCRETE PAD

120 Glasgow Avenue

Inglewood, California 90301

U.S.A.

Model 9150 is intended for installation only on sliding gates used for vehicles.

Pedestrians must be supplied with a separate access opening. For safety and installation instructions, please refer to the Installation/Owner’s manual.

Copyright 2010 DoorKing, Inc. All rights reserved.

9150-066-E-8-10

Concrete pad

MUST be level!

This depth of the concrete pad is

determined by soil conditions and

local building codes (reinfor

ced

concrete recommended).

Loosen the 2 nuts under the

electronic box to swing box up.

Use 3/4-inch

co

nduit

with sweeps.

Use (4) 3/8” x 2”

Sleeve Anchors

(Not supplied).

Loop Conduit

AC Power

Conduit

4” minimum

above ground.

Opening

Direction

Switch 1

OFF

.

21.5” Minimum

26” Minimum

Idler

Wheel

Use existing

wire restrainers

to keep wire

away from

moving

parts.

Concrete Pad

• Chain MUST be parallel to gate!

• Chain bracket MUST line up with

idler

wheels!

Chain brackets

MUST be mounted

the same height as

the chain on the

idler wheels!

Chain

Bracket

SW 1

1

2345678

ON

Opening

Direction

Switch 1

ON

.

SW 1

1

2345678

ON

B

B

A

C

High Voltage Connection

Tip:

It is recommended that a surge suppressor be

installed on the high voltage power lines.

GATE OPERATOR MUST BE PROPERLY GROUNDED!!

The 9150’s open/close limits DO NOT have to be

physically adjusted. Every time the 9150 is powered

up, the first open command will automatically run

“2 open/close gate cycles” that will locate and

remember the gate’s open and close limit

positions. These limit positions are determined by

where the physical stops have been installed. It does

not matter what position the gate is in before

running this sequence. The gate will function

normally after this automatic sequence

has finished.

Adjust the chain nuts to tighten the chain.

The chain should sag no more than one

(1) inch per 10 feet of chain travel.

Do not over tighten the chain.

Automatic Limits

Chain Adjustment

Note:

Auto-close timer should be

on before running this sequence.

115 VAC

Chassis Ground

White - Neutral

Black - 115 VAC Hot

Green - Chassis Ground

Hot Neu

Every time the 9150 is powered up, the First open

command will automatically run “2 open/close gate

cycles” that will locate and remember the gate’s open

and close limit positions. See “Automatic Open/Close

Limit Adjustment” in Installation/Owner’s manual for

more information.

208/230/460 VAC

Chassis Ground

For 208, 230 and 460 Volt

3-phase input, use only two legs

of the incoming 3-phase power.

1” minimum space between the gate and the operator housing.

21.5”

Min.

26” Min.

Concrete Pad and Conduit Area

Circuit Board Settings

ON

1

2

345678

SW 2

ON

1

2

345678

SW 1

1. Opening Direction (See Illustration)

2.

ON

3. OFF

4. OFF

5. OFF

6. OFF

7. OFF

8. OFF

1.

ON

2. OFF

3. OFF

4. OFF

5. OFF

6. OFF

7. OFF

8. OFF

Auto-Close Timer

Adjust 1 to

23 sec.

1

23

Note:

SW 2, switch 1 is

turned on when plug-in

exit loop detector is

installed.

SW 1, Switch 1 -

Must OPEN the gate upon initial AC

power up and open command. If the open command

begins to close the gate, turn AC power off and

reverse this switch.

“Basic” Setting of DIP-Switches

OPEN

TIMER

Cycles the operator

when pressed.

Key Switch

High Voltage

AC Input Wire

High Voltage

AC Input Wire

B

Radio Receiver

C

Not included - Refer to a specific Radio Receiver

Manual (available from

www.dkaccess.com

) for

more information on radio receivers and antenna

installation.

Plug-In Loop Detectors

Not included - Refer to the Installation/Owner’s

manual AND Loop Information Manual (available from

www.dkaccess.com

) for more information on loops

and plug-in loop detectors.

Important Note:

DoorKing highly recommends that

loops and loop detectors are installed with this slide

gate operator. A loop detection system will preventing

the gate from automatically opening or closing on a

vehicle when it is in the gate’s path.

DO NOT

power up and cycle the operator without “Physical Stops” installed

to stop the gate in the open and close positions, (Chain stops are included with

the operator but other physical stops can be used) damage could occur to the

gate and operator.

Chain stop’s rubber

bumpers face toward

operator. They will make

contact with the operator

housing during the initial

automatic open/close

limits setting

sequence.

Physical Stops MUST be Used to Stop Gate

Anti-

Grounding

Plate

Connect Chain

Bracket

and

Chain

to Gate

Chain

Nut

Chain

Bolt

Option 2

Maste

r

Link

Option 1

Gate

Frame

Chain nut and

chain bolt should not

protrude past gate frame.

Wire

Restrainer

Power safety and opening devices

that require 115 VAC power.

Two 115 VAC Convenience Outlets