Maintenance (continued) – CM-ET Series 653 User Manual

Page 12

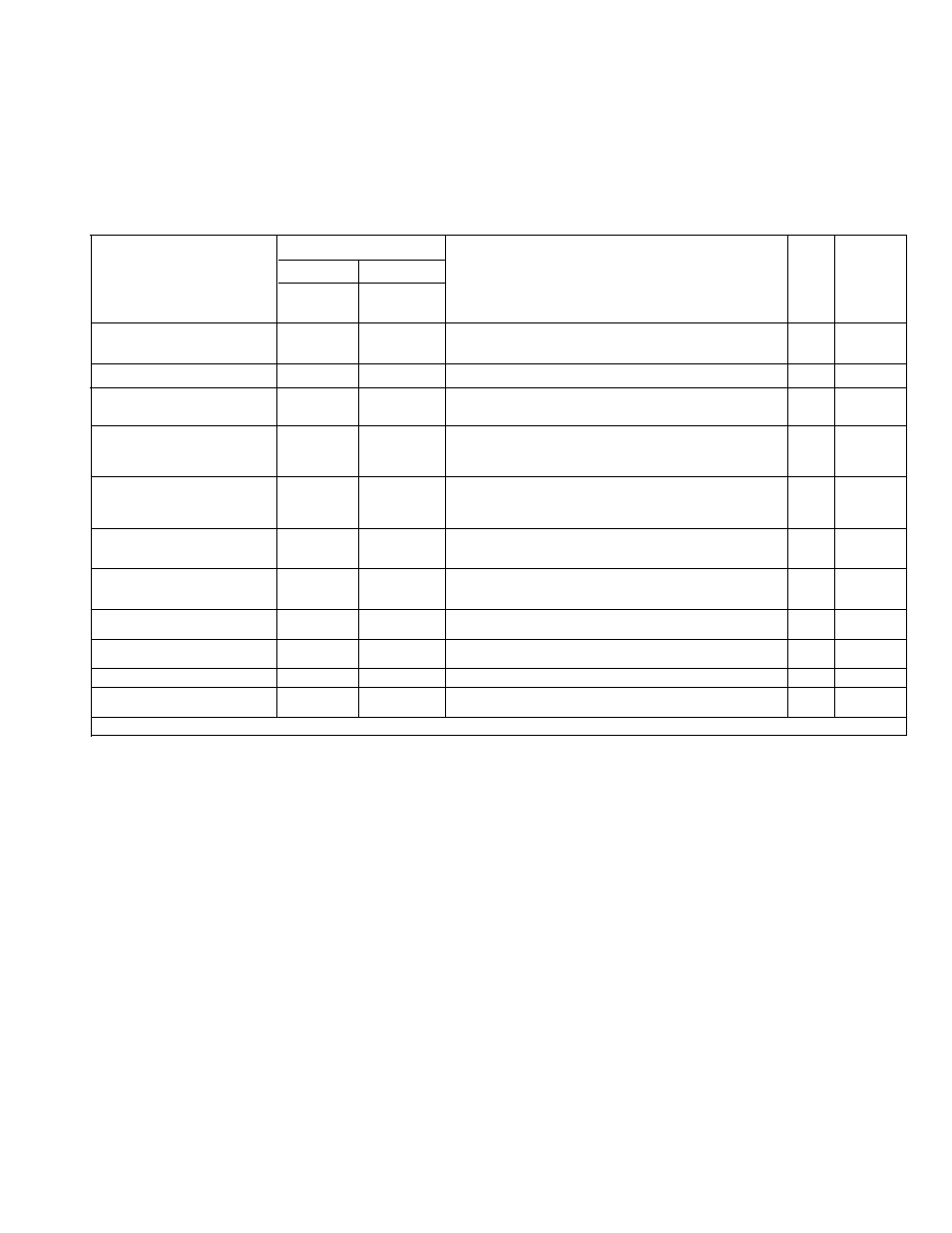

INSPECTION AND MAINTENANCE CHECK LIST

HAND OPERATED LEVER HOIST

Type of Hoist ___________________________________________________________

Capacity (Tons)________________________________________________________

Location _______________________________________________________________

Original Installation Date ______________________________________________

Manufacturer___________________________________________________________

Manufacturer’s Serial No. ______________________________________________

Item

Frequency of Inspection

Possible Deficiencies

OK

Action

Frequent Periodic

Required

Daily

Every 3 Months

Brake Mechanism

*

*

Slippage or excessive drift.

Worn, glazed or contaminated friction discs. Thickness of discs

less than 0.094 inches.

Directional Lever

*

*

Binding and does not move freely.

Inadequate lubrication, excessive wear or stretch, cracked

Load Chain

* * damaged or twisted links, corroded or clogged with foreign

material.

Hooks

*

*

Excessive throat opening, twisted more than 10 º, damaged

or non-operating hook latch, chemical damage. Cracks (Use dye

penetrant, magnetic or other suitable detection method at

least once a year).

Lower Hook Block, Upper Hook

Cracks, distortion, excessive wear, corrosion or build-up of

Block, Upper Hook Pin, Chain Guide

*

foreign material.

Rollers, Bushings, Gears, Pinion and

Friction Hub

Tip of Pawls and Lever Pawl

Cracks, distortion, excessive wear, corrosion or build-up of

Teeth of Ratchet and Lever Ratchet

of foreign material.

*

Pockets of Liftwheel, Stripper

Cracks, distortion, excessive wear, corrosion or build-up of

and Side Plates

*

foreign material.

Nuts, Bolts, Pins and Rivets

*

Cracks, bending, loose, stripped threads.

Pawl Springs, Directional Pawl

Corrosion, stretched or broken.

Spring, and Spring

*

Chain Stop

*

Missing, cracked, not secured to chain, not properly positioned.

Nameplate, Warning Labels and

Free Chaining Tags

*

Missing, Damaged or illegible.

NOTE:

Refer to Maintenance and Inspection Sections of this manual for further details.

FREQUENCY OF INSPECTION

Frequent - Indicates items requiring inspection daily or before each use. These inspections may be performed by the operator if properly designated.

Periodic -- Indicates items requiring inspection every three months. Inspections to be performed by or under the direction of a properly designated person. The

exact period of inspection will depend on frequency and type of usage. Determination of this period will be based on the user’s experience. It is

recommended that the user begin with a quarterly inspection and extend the periods to semi-annually or annually based on the user’s quarterly

experience.

NOTE

: This inspection and maintenance check list is in accordance with our interpretation of the requirements of the Safety

Standard for Overhead Hoists ASME B30.16. It is, however, the ultimate responsibility of the employer/user to interpret and

adhere to the applicable requirements of this safety standard.

9

Maintenance (Continued)

Figure 14 — Recommended Inspection and Maintenance Check List