Maintenance (continued) – CM-ET Series 653 User Manual

Page 10

Maintenance (Continued)

2. To replace the liftwheel or stripper,

completely disassemble the unit:

remove the chain (See REPLACING

LOAD CHAIN, page 7) and then

remove the brake nut, cotter pin and

spacer (19), free chaining knob (17),

lever (16), check washer (18), lever

ratchet (33), brake cover (14), friction

discs (12), ratchet (13), spring (6) and

friction hub (11). On the gear side,

remove the gear cover (8), gears (5)

and pinion (7). Remove snap ring and

liftwheel gear (23). Being careful not

to loose the rollers, remove the side

plate assembly (1). Slide the liftwheel

(22) out of the side plate (2), being

careful not to loose the rollers. The

stripper (4) can also be removed now.

Prior to re-assembly, check all parts

for excessive wear, cracks and

distortion. Replace parts as necessary

and then re-assemble the unit in

reverse to the order given above,

making sure to install the chain guide

rollers (10) and upper hook (25) and

pin (26). After assembly, install the

chain (See REPLACING LOAD CHAIN,

page 7) and then test the unit (See

TESTING, page 8).

3. The latch is secured to the hook

(upper and lower) by a rivet. To

remove the latch, it is necessary to

remove the head of the rivet by

grinding or drilling. For the

replacement of the latch, refer to

the paragraphs under assembly

instructions.

ASSEMBLY:

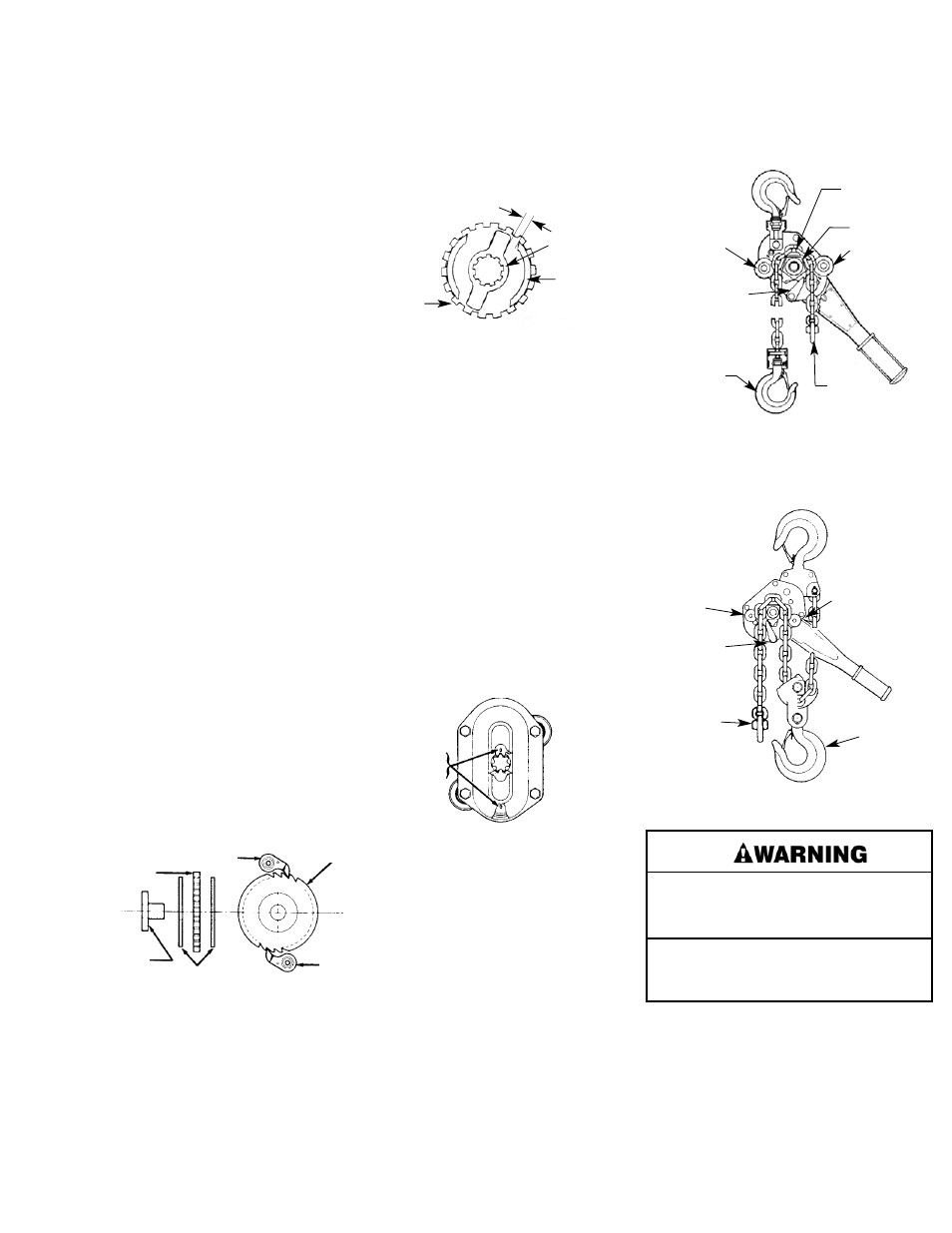

1. Thread the friction hub (11 ) onto the

pinion shaft (7 ) and assemble the

friction discs and the ratchet on the

friction hub (See Figure 8).

Place the spring (6) over the friction

hub and pinion. Place the brake cover

assembly (14) on the frame and thread

the lever ratchet (33) onto the pinion

shaft. Firmly seat the lever ratchet and

secure the brake cover assembly to the

frame using the four nuts (9).

Place the check washer (18) on the

pinion shaft so that there is 0.094 to

0.312 inches (2 to 8 mm) between the

edge of the check washer and the

raised stop on the lever ratchet hub

(See Figure 9).

Make sure the directional lever is in

the neutral (“N”) position and the

pawl, spring and shaft (20) are in the

lever assembly (16), attach the lever

assembly to the brake cover (14) using

the two locknuts, screw and

lockwasher (15). Place the free

chaining knob (17) on the lever

ratchet hub (33). Place the spacer (19)

over the pinion shaft, thread the

brake nut (19) onto the pinion shaft,

and firmly tighten the nut. Back off

the nut one to two flats and insert the

cotter pin (19). Bend the legs of the

cotter pin to secure.

2. When assembling the latch to the

hook, the end of the rivet must be

peened over. When peening over

rivet, only apply enough force to form

a head to retain the pin. Excessive

force will deform the latch and make

the latch inoperable.

3. When assembling the gears, they

must be orientated with the timing

marks aligned (See Figure 10).

REPLACING LOAD CHAIN

To replace the load chain, remove the

lower hook block and chain stop from

the chain. Move the directional lever to

the neutral “N” and pull the old chain

out of the hoist. Feed a length of soft

wire through one side of the chain

guide roller and over the liftwheel until

it comes out on the other side of the

chain guide roller. Attach the wire to

the end of the new chain. Position the

chain so that the first link to enter the

chain guide roller will be an upstanding

link and the welds on all upstanding

links will be away from the liftwheel.

Pull on the wire until the chain engages

the liftwheel. Turn the free chaining

knob, while pulling on the wire, until

the chain comes out of the chain guide

roller. Pull the chain through and

remove the wire. On the 3/4, 1, 1 1/2, 2

and 3 Ton units attach the lower hook

block to the chain that is directly below

the upper hook. On the 6 Ton unit,

reeve the chain as shown below. Attach

the chain stop to the other end of the

chain.

RECOMMENDED SPARE PARTS

To insure continued operation, it is

recommended that two friction

discs (12) for each Series 653 lever

hoist in service, be kept on hand

at all times to replace friction

washers that are worn,contamin-

ated or glazed.

7

Chain welds

away from

Liftwheel

Liftwheel

Chain guide

roller-Chain

Stop Side

Stripper

Chain guide

roller-Lower

Hook Side

Lower

Hook

Block

Chain Stop-

Position as

Shown

Ratchet

Friction

Hub

Friction Disc

Pawl

Ratchet

Pawl

Figure 8 - Brake Assembly

Raised

Stop

Lever

Ratchet

Check

Washer

Figure 9 - Position of Check Washer

Timing

Marks

Figure 10 - Gear Timing

Chain Installation-3/4, 1, 1½, 2 and 3 Ton

0.094 to 0.312 IN.

(2 to 8mm)

Alterations or modifications of equipment and

use of any parts other than Series 653 repair

parts can lead to dangerous operation and

injury.

TO AVOID INJURY:

Do not alter or modify equipment. Do use only

Series 653 provided replacement parts.

Chain Guide

Roller-End

Ring Side

Chain Guide

Roller-Hook

Side

Figure 11. Reeving - 6 Ton

Stripper

End Ring

Lower

Hook

Block