Maintenance (continued) – CM-ET Series 653 User Manual

Page 11

Maintenance (Continued)

PREVENTATIVE MAINTENANCE

In addition to the inspection

procedures, a preventative maintenance

program should be established to

prolong the useful life of the hoist and

maintain its dependability and

continued safe use. The program should

include the periodic inspections with

particular attention being paid to the

lubrication of various components using

the recommended lubricants (See

Figure 13).

TESTING

Prior to initial use, all repaired or used

hoists that have not been operated for

the previous 12 months shall be tested

by the user for proper operation.

Test the unit first in the unloaded state

and then with a light load of 100

pounds (45 kg.) times the number of

load supporting parts of load chains to

be sure it operates properly and the

brake holds the load when the lever is

released; then test with a load of 125%

of rated capacity.

In addition, hoists in which load

sustaining parts have been replaced

must be tested with 125% of rated

capacity by or under the direction of a

designated person and a written report

prepared for record purposes.

NOTE:

For additional information on

Inspection and Testing refer to ASME

B30.21 “Manually Lever Operated

Hoists” obtainable from ASME Order

Department, 22 Law Drive, Box 2300,

Fairfield, NJ 07007-2300, U.S.A.

8

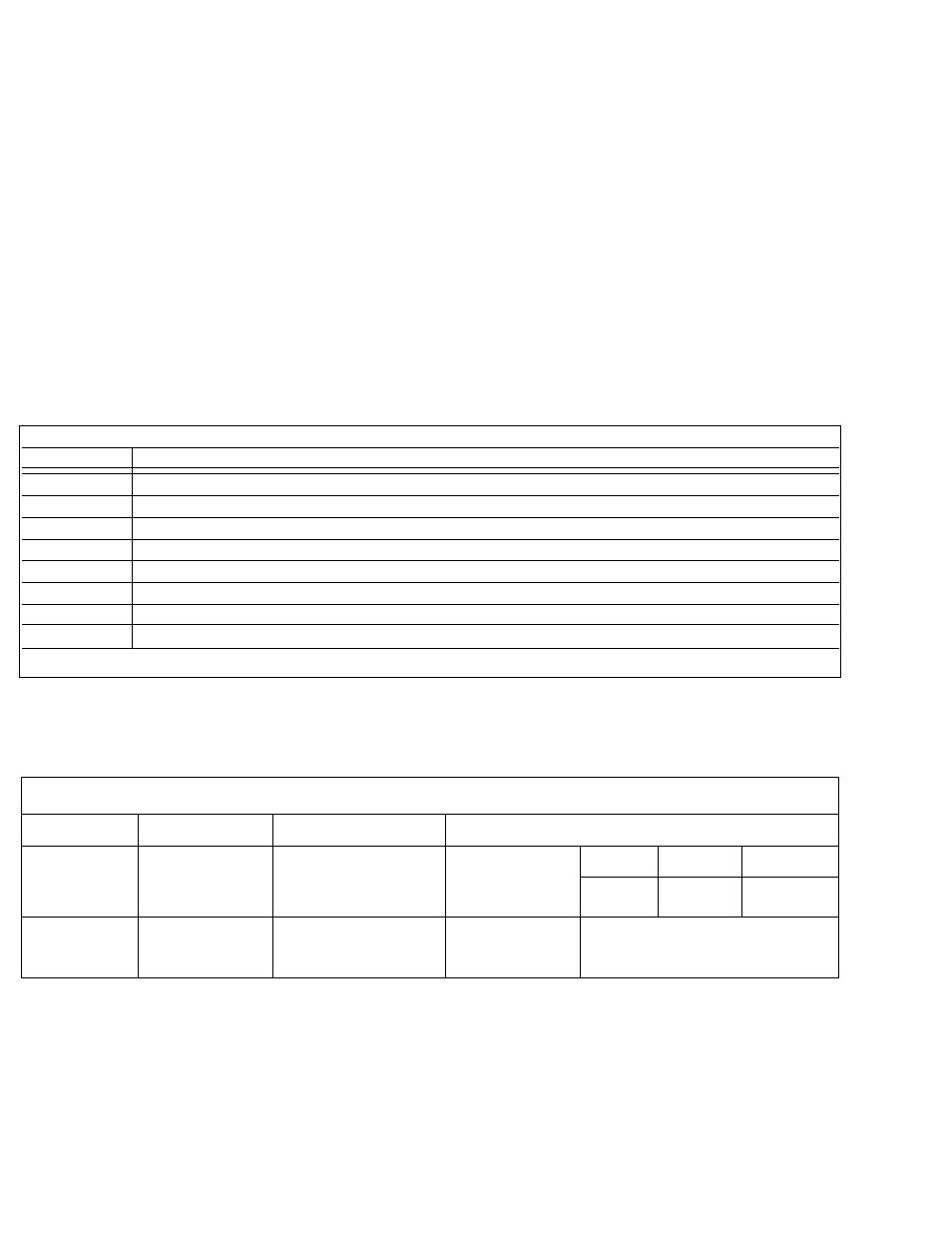

INSPECTOR’S REPORT

ITEM

REMARKS (LIST DEFICIENCIES AND RECOMMENDED ACTION)

Inspector’s

Date

Signature

Inspected

Approved by

Date

Figure 12 — Recommended Inspector’s Report

(*) This lubrication schedule is based on a hoist operating in normal environment conditions. Hoists operating in adverse atmospheres

containing excessive heat, corrosive fumes or vapors, abrasive dust, etc., should be lubricated more frequently.

RECOMMENDED LUBRICATION SCHEDULE*

SERIES 653 HAND OPERATED LEVER HOISTS

REFERENCE NO.

COMPONENT TYPE OF LUBRICANT ORDER

TYPE OF SERVICE AND

(SEE PAGES 12 & 13)

PART NO.

FREQUENCY OF LUBRICATION

HEAVY

NORMAL

INFREQUENT

32

Load Chain

Oil (See Page 6) 28619

Daily

Weekly

Monthly

(1 gal. can)

Gears, Bushings,

5, 1, 8, 24 & 7

Liftwheel rollers Grease (See page 6) 28618

When hoist is disassembled for cleaning

& Pinion shaft

(1 lb. can)

or repairs

Figure 13 — Recommended Lubrication Schedule