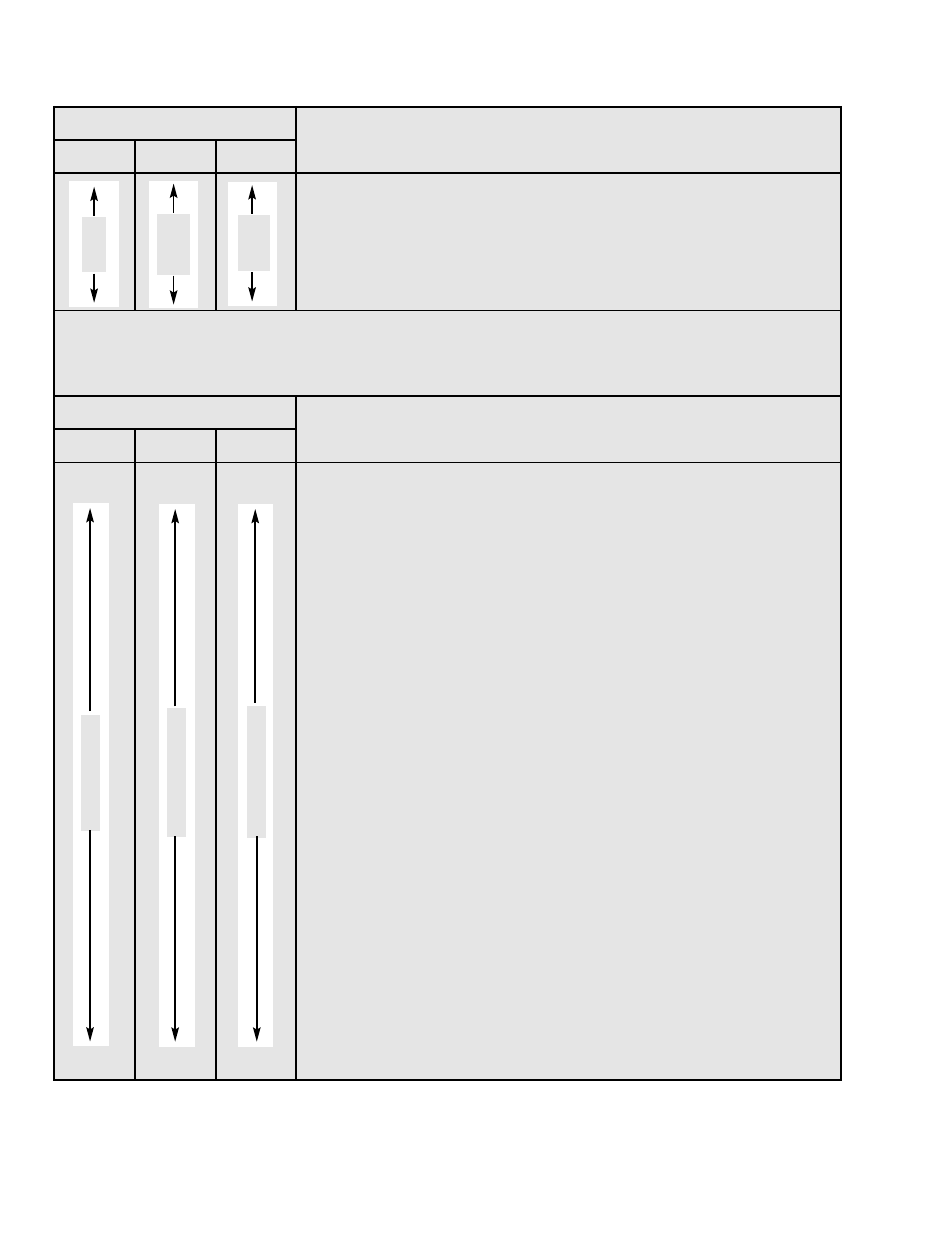

Type of service, Table 4. minimum frequent inspections 9, Item normal heavy severe – CM-ET Lodestar User Manual

Page 13

TYPE OF SERVICE

ITEM

Normal

Heavy

Severe

a) Brake for evidence of slippage.

b) Control functions for proper operation.

c) Hooks for damage, cracks, twists, excessive throat opening, latch engagement and latch

operation - see page 10.

d) Load chain for adequate lubrication, as well as for signs of wear, damaged links or foreign

matter - see page 10.

e) Load chain for proper reeving and twists.

Table 5. Minimum Periodic Inspections

TYPE OF SERVICE

ITEM

Normal

Heavy

Severe

a) All items listed in Table 4 for frequent inspections.

b) External evidence of loose screws, bolts or nuts.

c) External evidence of worn, corroded, cracked or distorted hook block, suspension screws,

gears, bearings and dead end block and chain pin.

d) External evidence of damage to hook retaining nut and pin. Also check the upper suspen-

sion adapter making sure it is fully seated in the hoist frame and that both screws are tight.

e) External evidence of damage or excessive wear of the liftwheel and hook block sheave

chain pockets. Widening and deepening of the pockets may cause the chain to lift-up in

the pocket and result in binding between liftwheel and chain guides or between the sheave

and hook block. Also, check the chain guide for wear or burring where the chain enters the

hoist. Severely worn or damaged parts should be replaced.

f) External evidence of excessive wear of brake parts, and brake adjustment - see page 11.

g) External evidence of pitting or any deterioration of contactor contacts. Check the opera-

tion of the control station making sure the buttons operate freely and do not stick in either

position.

h) Inspect the electrical cords and cables and control station enclosure for damaged insulation.

i) Inspect trolley trackwheels for external wear on tread and flange and for wear on internal

bearing surfaces as evidenced by a looseness on the stud. Suspension components for

damage, cracks, wear and operation. Also check suspension adapter screws for proper

tightness - see page 4.

j) Inspect the loose end link, loose end screw and dead end block on double reeved units.

Replace worn or distorted parts.

k) Inspect the suspension lug or hook for excess free play or rotation. Replace worn parts as

evidenced by excess free play or rotation.

l) Inspect for signs of lubricant leaks at the gasket between the gear housing and back

frame. tighten screws holding back frame to gear housing. If leak persists, repack housing

and gears with grease and install a new gasket.

Monthly

W

eekly

to Monthly

Daily

to W

eekly

Y

early

Every 6 Months

Every 3 Months

Table 4. Minimum Frequent Inspections

9