Installation, Selection of mounting location, Mounting surface preparation – Cleveland Motion Controls Classic Tension Transducers SC-EP REV GA User Manual

Page 7: General installation information, Installation precautions, 4 installation, Precautions

Cleveland-Kidder Transducers; EC, ECM, SC, SCM & SC-EP

A800-7438 Rev GA

P

AGE

7

OF

10

2 INSTALLATION

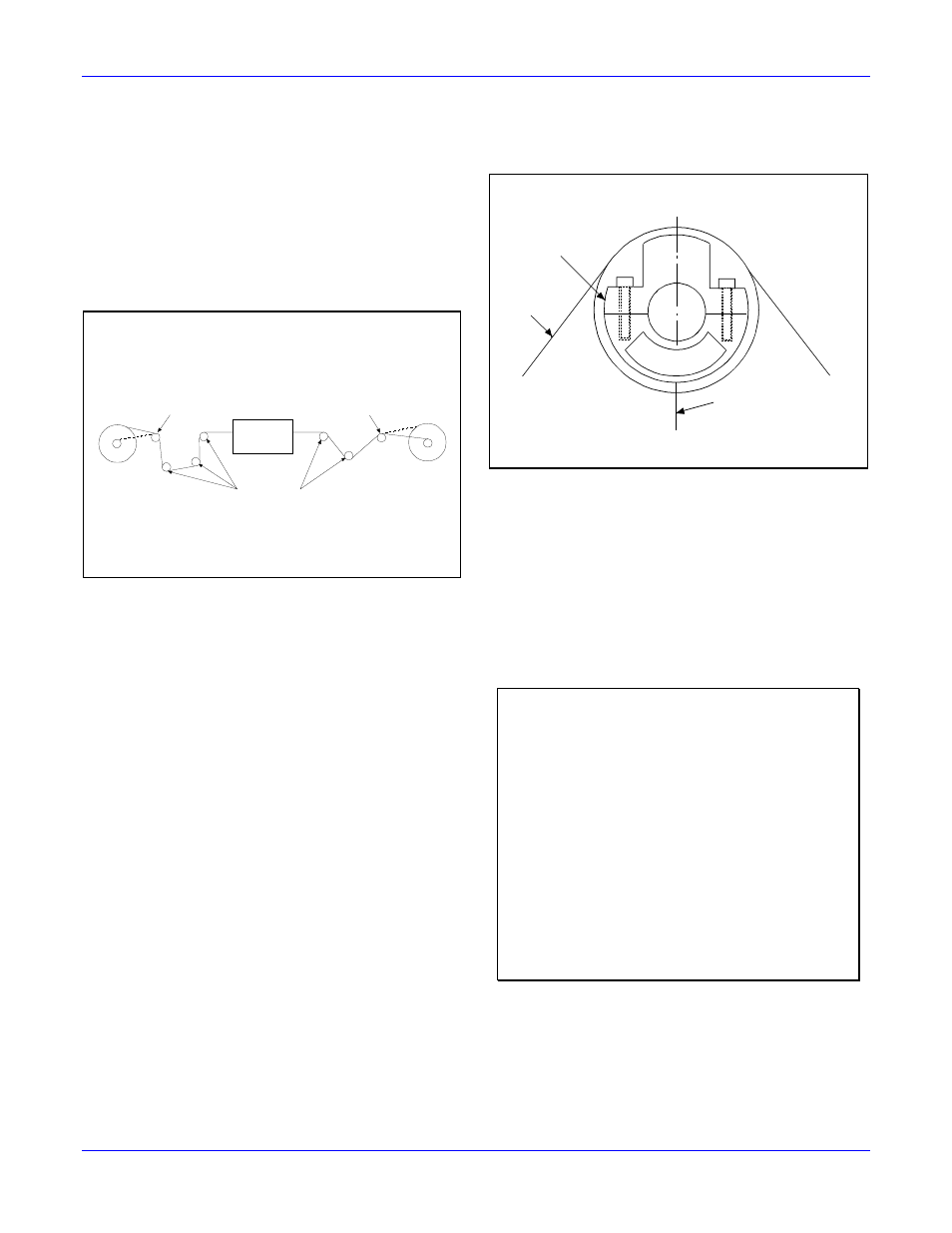

2.1 SELECTION OF MOUNTING LOCATION

When selecting a transducer mounting location,

keep in mind that the tension sensing roll must

NOT be mounted where the web wrap angle can

vary. Any change in the wrap angle will be sensed

by the transducers as a change in tension, and

indicated as such on the tension indicator.

Figure 3

In some cases, it may be impossible to find a

location for the transducers where the wrap angle

does not vary. The change in indicated tension

which will result can be calculated and, if small,

may not be significant.

2.2 MOUNTING SURFACE PREPARATION

The mounting surfaces for the transducers should

be flat and parallel. Prepare the machine frames or

mounting surfaces by removing any loose paint,

rust, scale, etc.

2.3 GENERAL INSTALLATION INFORMATION

The transducers must be mounted so that the

applied web force is approximately perpendicular

to the solid half of the shaft supporting socket.

See Figure 4 and the instructions on page 8 for

your particular transducer type and orientation.

Figure 4

2.4 INSTALLATION PRECAUTIONS

To insure proper installation and operation of the

system, the following steps should be performed

in sequence. Failure to do so could seriously

damage the transducers and void the warranty.

PRECAUTION:

Always install, orient and firmly bolt down

the transducers BEFORE installing the

tension sensing roll. When disassembling

and installation, DO NOT remove the

transducer an the tension sensing roll as

an assembly - remove the roll first, before

loosening the transducer mounting bolts.

DO NOT rotate transducers (for

orientation) with the tension sensing roll

installed. Damage may result.

WRAP VARIES

WRAP VARIES

OK FOR TENSION SENSING

UNWIND

REWIND

PROCESS

TRANSDUCER CAP

WEB

WRAP ANGLE BISECTOR

SHOULD BE PERPENDICULAR

TO TRANSDUCER CAP

LOAD IN THIS

DIRECTION