Silver series, Installation instructions – KING Silver Series User Manual

Page 5

(714) 891-0008 • www.kinginstrumentco.com

When it comes to flow...we’re instrumental.

5

Silver Series

Installation Instructions

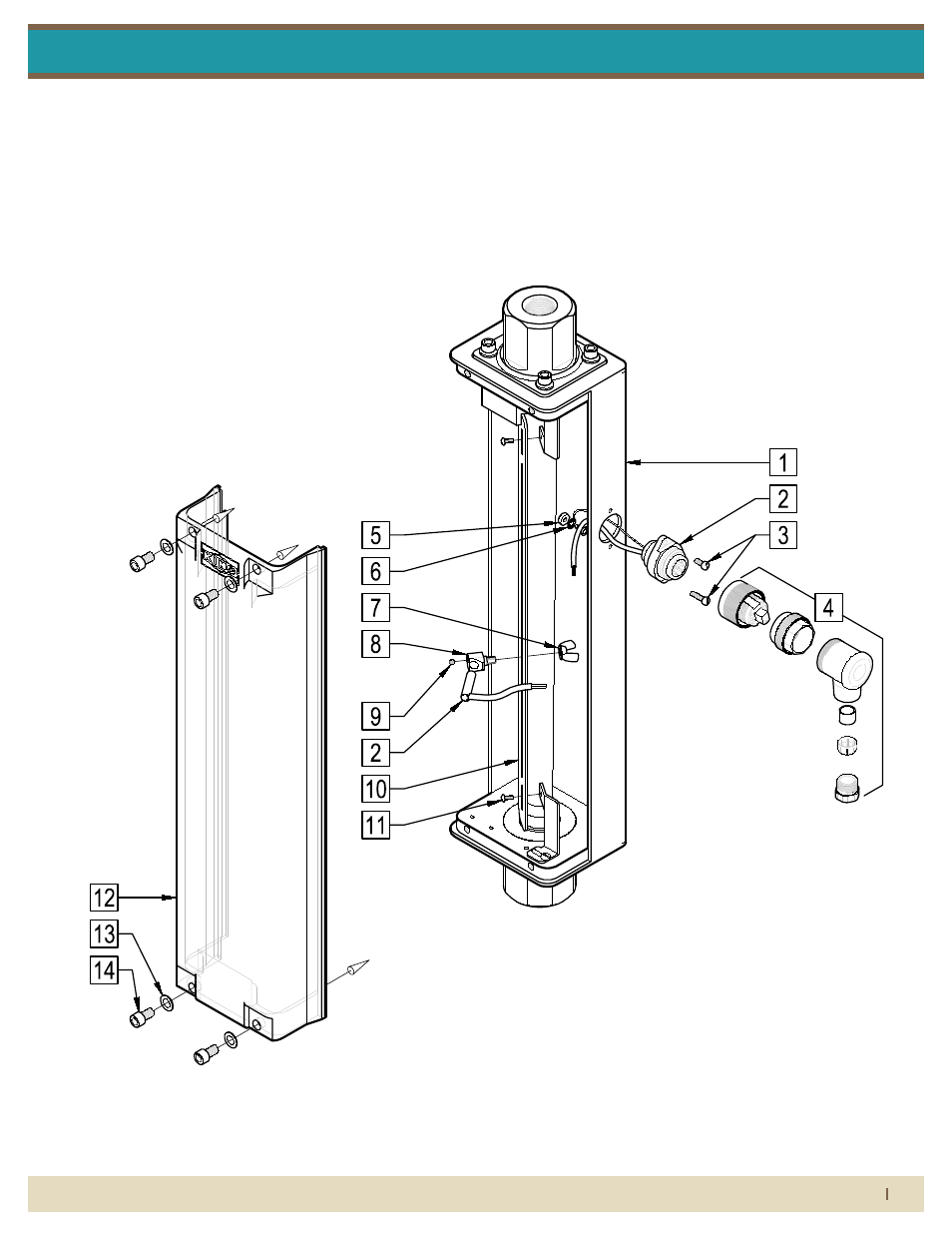

silver series asseMbly with alarM

parts list:

1. Meter Assembly

2. Alarm Switch Assembly

3. Alarm Switch Assembly Screw

4. Alarm Connector Plug

5. Ground Nut

6. Ground Lock Washer

7. Alarm Switch Housing Wing Nut

8. Alarm Switch Housing

9. Alarm Switch Housing Set Screw

10. Alarm Scale Plate

11. Alarm Scale Plate Screw

12. Shield

13. Shield Flat Washer

14. Shield Screw

1) Inspect meter for damage that may have occurred during shipping. Report any

damage to the container to the freight carrier immediately.

This is important information. Read it carefully before

beginning work.

2) Make sure your pressure, temperature, fluid and other requirements are

compatible with the meter.

3) Select a suitable location for installation to prevent excess stress on the meter

which may result from:

a) Misaligned pipe.

b) The weight of related plumbing.

c) "Water Hammer" which is most likely to occur when flow is suddenly stopped

as with quick closing solenoid operated valves. (If necessary, a surge chamber

should be installed. This will also be useful in pressure start-up situations.)

d) Thermal expansion of liquid in a stagnated or valve isolated system.

e) Instantaneous pressurization which will stress the meter and could result in

tube failure.

NOTE: In closed thermal transfer or cooling systems, install the meter in the cool

side of the line to minimize meter expansion and contraction and possible fluid

leaks at the threaded connections.

4) Handle the meter carefully during installation.

a) Use an appropriate amount of teflon tape on external pipe threads before

making connections. Do not use paste or stick type thread sealing products.

5) Install the meter vertically with the inlet port at the bottom.

6) Meters with stainless steel fittings will support several feet of pipe as long as

significant vibration or stress resulting from misaligned pipe are not factors.

Maximum Non-Shock

Pressure and Temperature O-Ring Temperature

Viton and Kalrez are registered trademarks of DuPont Dow Elastomers.

METER ASSEMBLY

ALARM SWITCH ASSEMBLY

ALARM SWITCH ASSEMBLY SCREW

ALARM CONNECTOR PLUG

GROUND NUT

GROUND LOCK WASHER

ALARM SWITCH HOUSING WING NUT

ALARM SWITCH HOUSING

ALARM SWITCH HOUSING SET SCREW

ALARM SCALE PLATE

ALARM SCALE PLATE SCREW

SHIELD

SHIELD FLAT WASHER

SHIELD SCREW

Temperature Pressure

Ambient temperature

33° F - 125° F

EPR

225 °F

Buna-N

Viton

Kalrez

275 °F

350 °F

400 °F

250 psig

(51W-67W)

150 psig

(81W-95W)

300 psig

(31W-47W)

130°F

200°F

PVDF

316LSS

Maximum

Temperature

O-Ring

Material

150 psig

(31W-95W)

b) Over tightening of plastic connections may result in fitting damage.

7) Meters with plastic fittings must be installed so that fittings are not made to

support any part of the associated plumbing. In addition, meter frame should be

fastened to bulkhead, panel or column.

8) Meters used in gas service should have suitable valves plumbed in at the inlet

and outlet of the meter. These valves should be no more than 1-1/2 pipe diameters

from the meter ports. The valve at the outlet should be used to create back

pressure as required to prevent float bounce. It should be set initially and then left

alone. The inlet valve should be used for throttling purposes. Depending on the

installation, valves may not be essential, but they are most useful in many

installations. Remember: To get a correct reading of flow in gas service, it is

necessary to know the pressure right at the outlet of the meter (before the valve).

9) Pressure and temperature maximums must never be exceeded.

2X

4X

4X