Hach-Lange ISENa38103 User Manual

Page 13

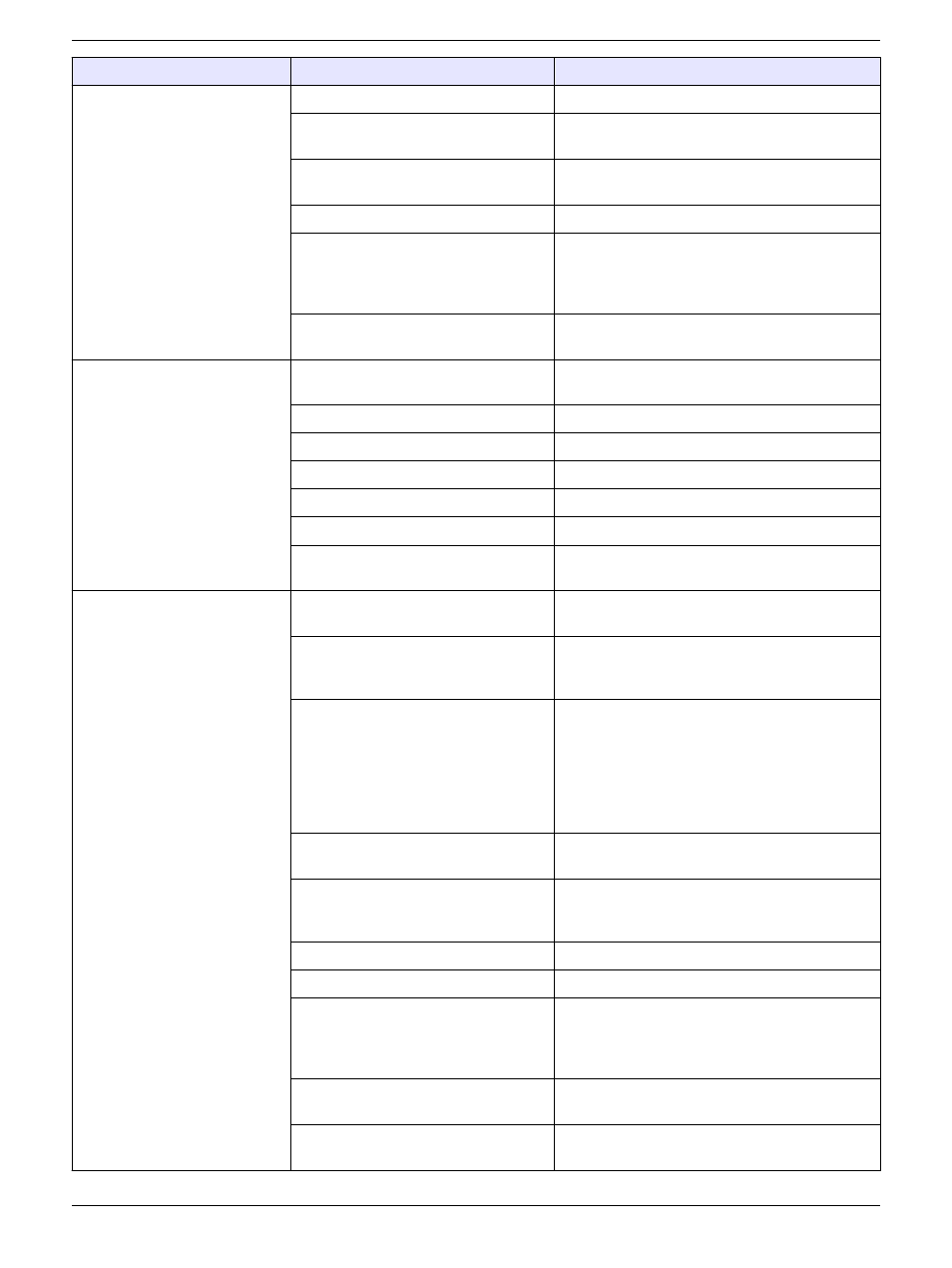

Message or symptom

Possible cause

Action

Slow stabilization time

Tape not removed from the filling hole

Remove the tape.

Contaminated glass sensor

on page 11).

Contaminated filling solution

Drain and replace the filling solution with fresh

solution.

Filling-hole cap is closed

Open the filling-hole cap while in use.

Low sample temperature or

temperature difference between

samples

Check the sample temperature. The lower the

temperature or the greater the difference of

temperatures between samples, the longer the

response time.

Air bubbles around inner reference

electrode

Gently tap the probe with hand or shake the

probe downward to remove any air bubbles.

Slope out of range (refer to

on page 14)

pH is too low

Make sure the pH is greater than 9 after each

ISA addition.

Ionic strength adjustor (ISA) not used

Add ISA to each sample and standard.

Insufficient conditioning

Condition for at least 8 hours in storage solution.

Damaged probe

Contact a Technical Support Representative.

Incorrect standards

Calibrate using freshly prepared standards.

Contaminated glass sensor

Clean the probe and recalibrate.

Air bubbles around inner reference

electrode

Gently tap the probe with hand or shake the

probe downward to remove any air bubbles.

Drifting/inaccurate readings

Contaminated glass bulb

on page 11).

Clogged reference

Rinse the reference junction with ISA rinse

solution thoroughly and shake the probe

downward to remove any air bubbles.

Improper storage

conditions/dehydrated glass bulb

Clean or condition the probe and attempt another

calibration. The probe may not function correctly

if the probe has been left dry for extended

periods of time. To re-condition the glass sensor

and reference junctions, allow the probe to soak

in storage solution (that contains Sodium ISA) for

at least 8 hours before use.

Stabilization criteria not optimized for

the application

Adjust the stabilization criteria in the

Measurement Options menu.

Magnetic stirrers may generate

sufficient heat to change solution

temperature.

Put a piece of insulating material between the

stirrer and beaker.

Filling-hole cap is closed

Open the filling-hole cap while in use.

Damaged probe

Contact a Technical Support Representative.

Electromagnetic Forces (EMF) such as

voltaic cells, thermoelectric devices,

electrical generators, resistors and

transformers

Do not use in areas where EMF is present.

Colloidal and/or particulates in the

filling solution

Replace the filling solution, calibrate and retest.

Air bubbles around inner reference

electrode

Gently tap the probe with hand or shake the

probe downward to remove any air bubbles.

13