8417 sensor, Maintenance, Controller – Hach-Lange POLYMETRON 9500 pH_ORP Sensors User Manual User Manual

Page 8: Maintenance schedule

1. Unscrew the measurement chamber (No. 6).

2. Remove the protector covering the pH bulb and rinse with deionized water or pH buffer and store

in a safe place for future use.

3. Gently shake the sensor downward in the same manner as a clinical thermometer to remove any

trapped air bubbles.

4. Record the installation date on the label (No. 10).

5. Screw the measurement chamber back in place.

6. Assemble the 1/8" NPT input/output connections and connect the sample inlet to position No. 8

and the outlet to position No. 9.

7. Circulate the sample and check visually through the chamber for the absence of bubbles which

could affect the measurement.

8. Adjust the flow rate to approximately 150 mL/minute.

9. To avoid back pressure it is advisable to discharge the sample at atmospheric pressure into a

drain.

10. The device should be grounded (No. 4) to avoid any external electrical noise interference.

11. To avoid damage to the sensor, make sure the flow chamber is never empty. Make sure the glass

bulb is always immersed in water or buffer solution.

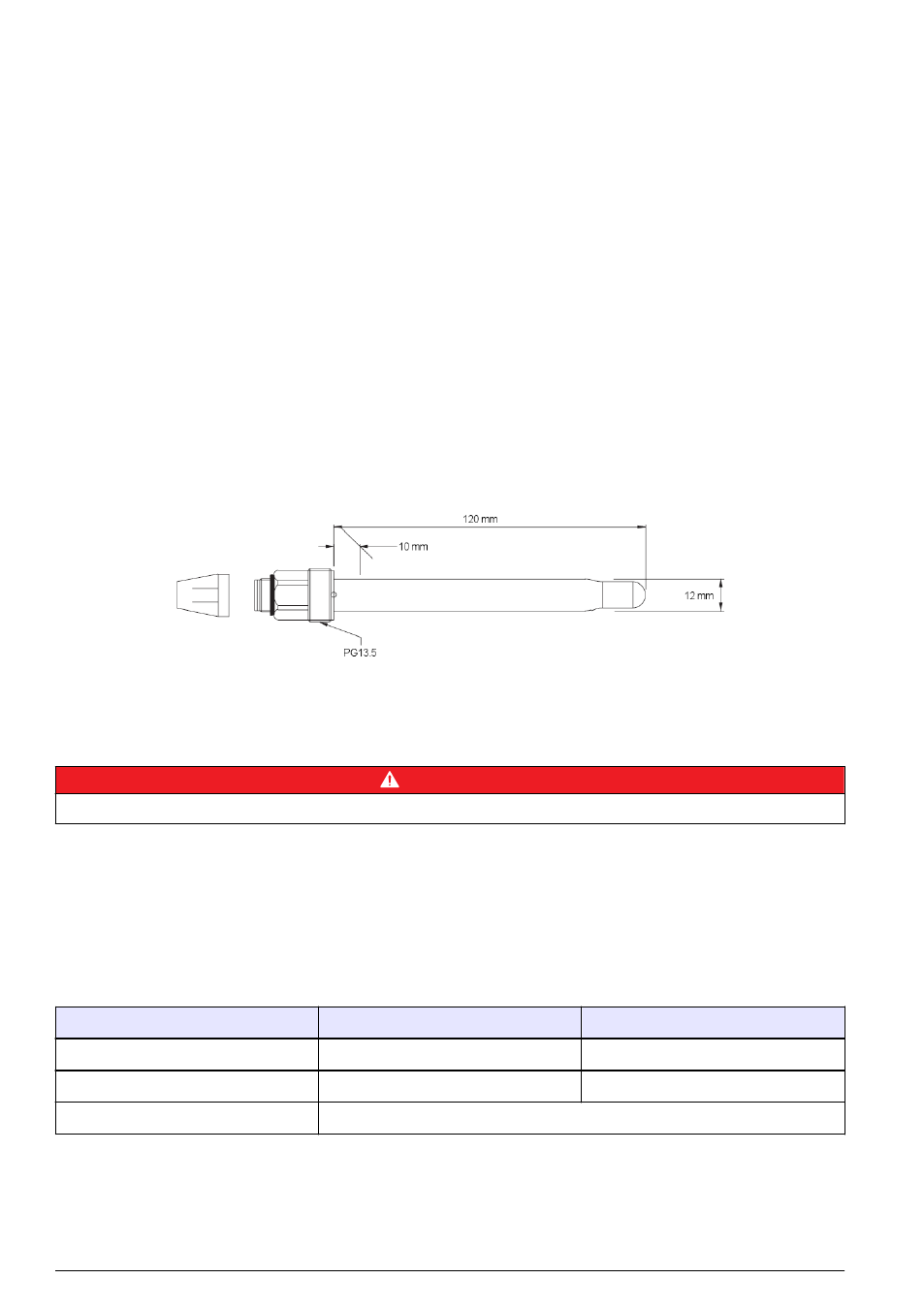

8417 sensor

The sensor can be installed in any position. Mount the sensor using a standard PG13.5 threaded

cap.

To avoid damage to the sensor, make sure the glass bulb is always immersed in water or buffer

solution.

Maintenance

D A N G E R

Multiple hazards. Only qualified personnel should conduct the tasks described in this section of the manual.

Controller

Refer to the Maintenance section of the controller documentation.

Maintenance schedule

The maintenance schedule shows minimum times for regular maintenance tasks. Perform

maintenance tasks more frequently for applications that cause electrode fouling.

Maintenance task

90 days

Annually

Clean the sensor

X

Inspect sensor for damage

X

Calibrate sensor

Set by regulatory agencies or experience

8 English