26 problem probable cause remedy – Hydrotech MP Series PULSAtron User Manual

Page 26

26

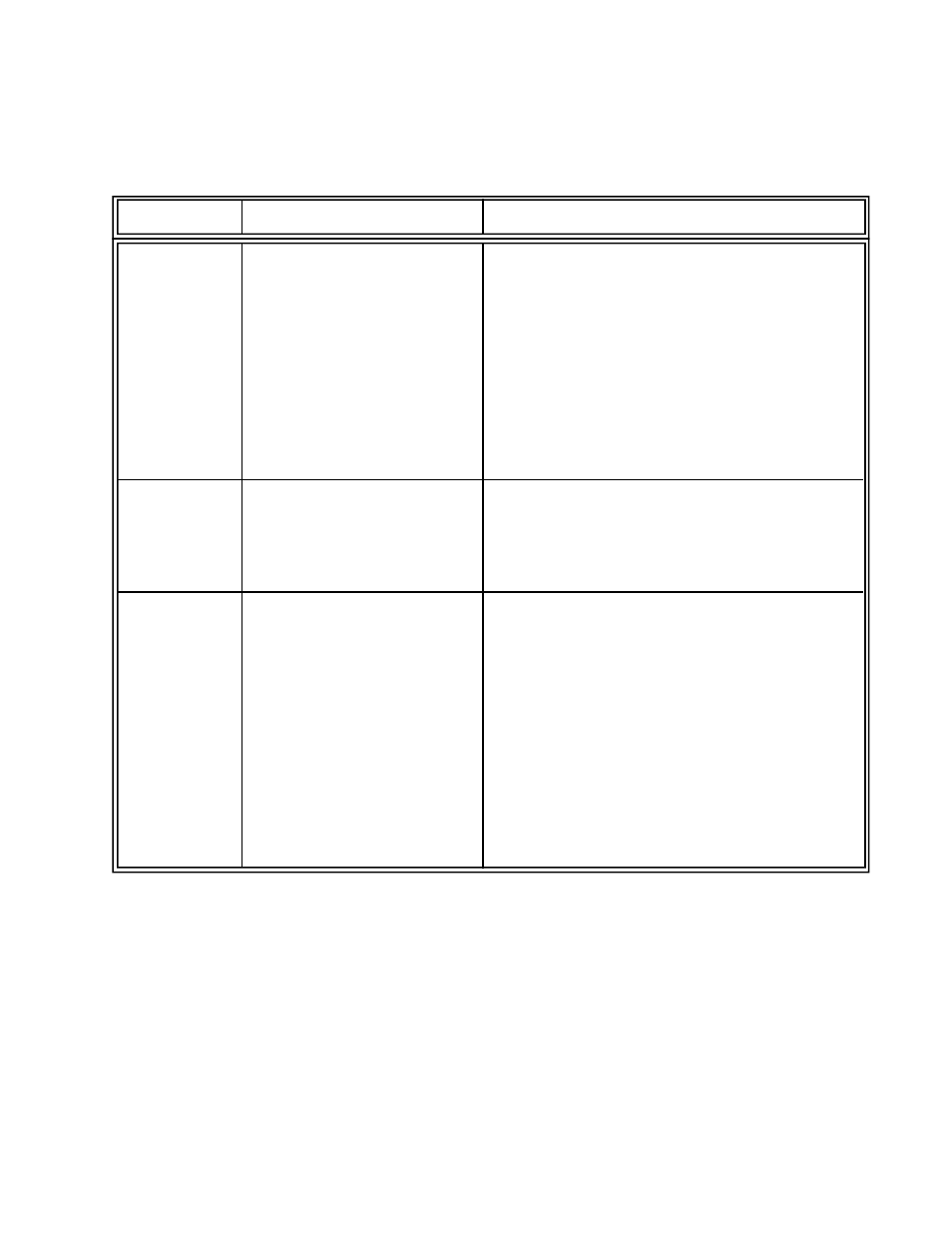

PROBLEM

PROBABLE CAUSE

REMEDY

1.

Dirty check valve

1.

Remove and replace or clean off any scale or sediment.

PUMP

2.

Ball checks not seating or

2.

Check seat and ball checks for chips, clean gently. If

LOSES

not sealing properly

deformity or deterioration is noted, replace part with

PRIME

proper material. Resulting crystals can hold check

valves open, therefore the valves must be disassembled

and cleaned. Be sure to replace all parts as shown in

the Parts Diagram (at the end of the manual).

3.

Solution container allowed

3.

Refill the tank with solution and prime. (See Start-Up

to run dry

and Operation Section).

4.

Chemical Outgassing

4.

Bleed gas, use flooded suction, maintain chemical at room

temperature (approx. 20

K

F / -6

K

C).

1.

Loose fittings

1.

Tighten hand tight. Replace gasket if hand tight does

not stop leakage

LEAKAGE

AT

FITTING

2.

Broken or twisted gasket

2.

Check gaskets and replace if broken or damaged.

3.

Chemical attack

3.

Consult your pump supplier for alternate material.

1.

Too much pressure at

1.

Turn off all pressure valves, loosen outlet tubing

discharge

connection at discharge point. Remove discharge valve

cartridge. Dampen ball check and valve seats with a few

drops of solution. Set pump dial to maximum rate.

When pump is primed, reconnect all tubing connections.

2.

Check valves not sealing

2.

Disassemble, loosen, clean and check for deterioration

PUMP WILL

swelling. Reassemble and wet the valve assembly,

NOT PRIME

then prime. See Start-Up and Operating Section.

3.

Output dials not set at

3.

Always prime pump with output dial set at maximum

maximum

rated capacity.

4.

Suction lift height too much

4.

Decrease suction lift or pull vacuum on pump discharge

until pump is primed.

5.

Pump equipped with spring

5.

Loosen discharge valve to aid in priming, take necessary

loaded high viscosity valves

safety precautions. Or apply vacuum to pump discharge.