Hydrotech MP Series PULSAtron User Manual

Page 19

19

6.

Turn the power on once more and adjust the pump flow to the desired rate (see “Controlling Procedure” below).

7.

Always check the calibration of the pump after start-up. It’s best to calibrate the pump under your typical use

conditions.

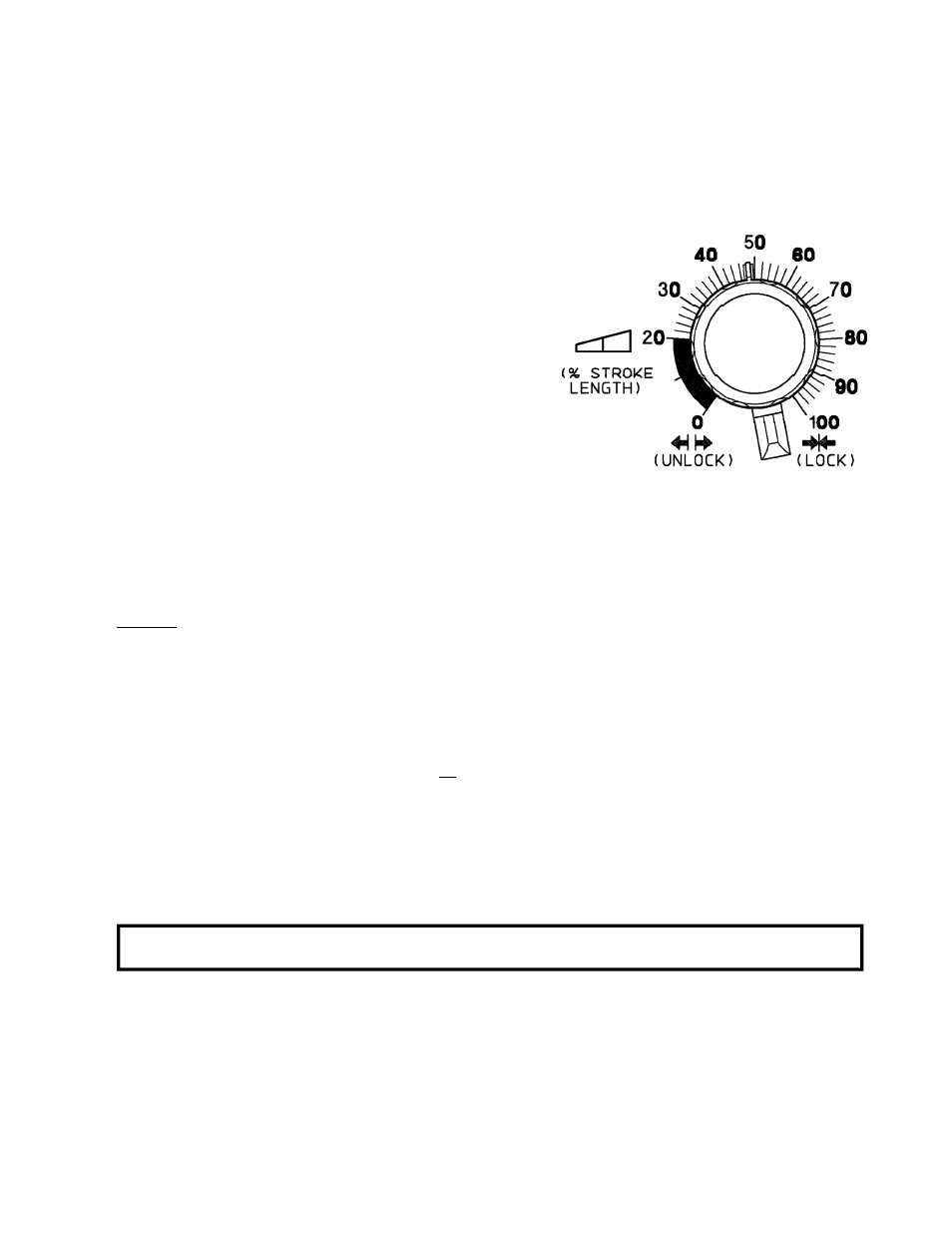

STROKE LENGTH ADJUSTMENT

M

Stroke length can be controlled within 0 to 100% of the

diaphragm displacement. (It should be controlled within 20

to 100% for practical use.)

M

Stroke length can be set by means of the stroke length

adjusting knob while the pump is in operation.

Do not turn

the knob while the pump is stopped.

Controlling Procedure (for fixed rate):

Proper set points for stroke length should be determined after consideration of the pump and characteristics of

the fluid. The following procedure is recommended from the viewpoint of pump performance.

Note: The closer

the stroke length is to 100%, the better the pump performance will be.

A)

Set the stroke length to 100%. Measure the output capacity.

B)

Adjust the stroke rate frequency to obtain the desired output. If adjustment by stroke rate alone does

not bring the output low enough, the stroke length may be adjusted to lower the maximum output.

C)

Measure the output capacity to ensure that the required value is obtained.

Example

Selected Model

=

LMD4

Set Stroke Length

=

100%

Set Stroke Rate

=

100%

Output Capacity

=

21 GPD*

(Rated Pressure)

Desired Flow

=

17 GPD

Adjust Stroke Rate to 81%

Output Capacity

=

17 x 100 = 81% (approx.)*

21

Thus to obtain the desired flow, stroke length is set at 100% and stroke rate

is set at 81% i.e. output capacity = 0.81 x 21 = 17 GPD*

* Check these values by measurement. Output capacity is higher when feeding against less than rated

pressure.

OPERATION BY EXTERNAL INPUT SIGNALS: