Maintenance instructions, Figure 7 figure 6 – Hydrotech ProFlo SXT Valve Downflow_Upflow Automatic Water Softeners Operation Manual User Manual

Page 13

Maintenance Instructions

Checking the Salt Level

Check the salt level monthly. Remove the lid from the cabinet or brine tank, make sure salt level is always above the

brine level (you should not be able to see water).

Adding Salt

Use only clean salt labeled for water conditioner use, such as crystal, pellet, nugget, button or solar. The use of rock salt

is discouraged because it contains insoluble silt and sand which build up in the brine tank and can cause problems with

the system’s operation.

Add the salt directly to the tank, filling no higher than the top of the brine well.

Caution

Liquid brine will irritate eyes, skin and open wounds - gently wash exposed area with fresh water. Keep children away

from your water conditioner.

Resin Cleaner

An approved resin cleaner must be used on a regular basis if your water supply contains iron. The amount of resin

cleaner and frequency of use is determined by the quantity of iron in your water (consult your local representative or

follow the directions on the resin cleaner package).

Care of Your Water Conditioner

To retain the attractive appearance of your new water conditioner, clean occasionally with a mild soap solution. Do no

use abrasive cleaners, ammonia or solvents. Never subject your conditioner to freezing.

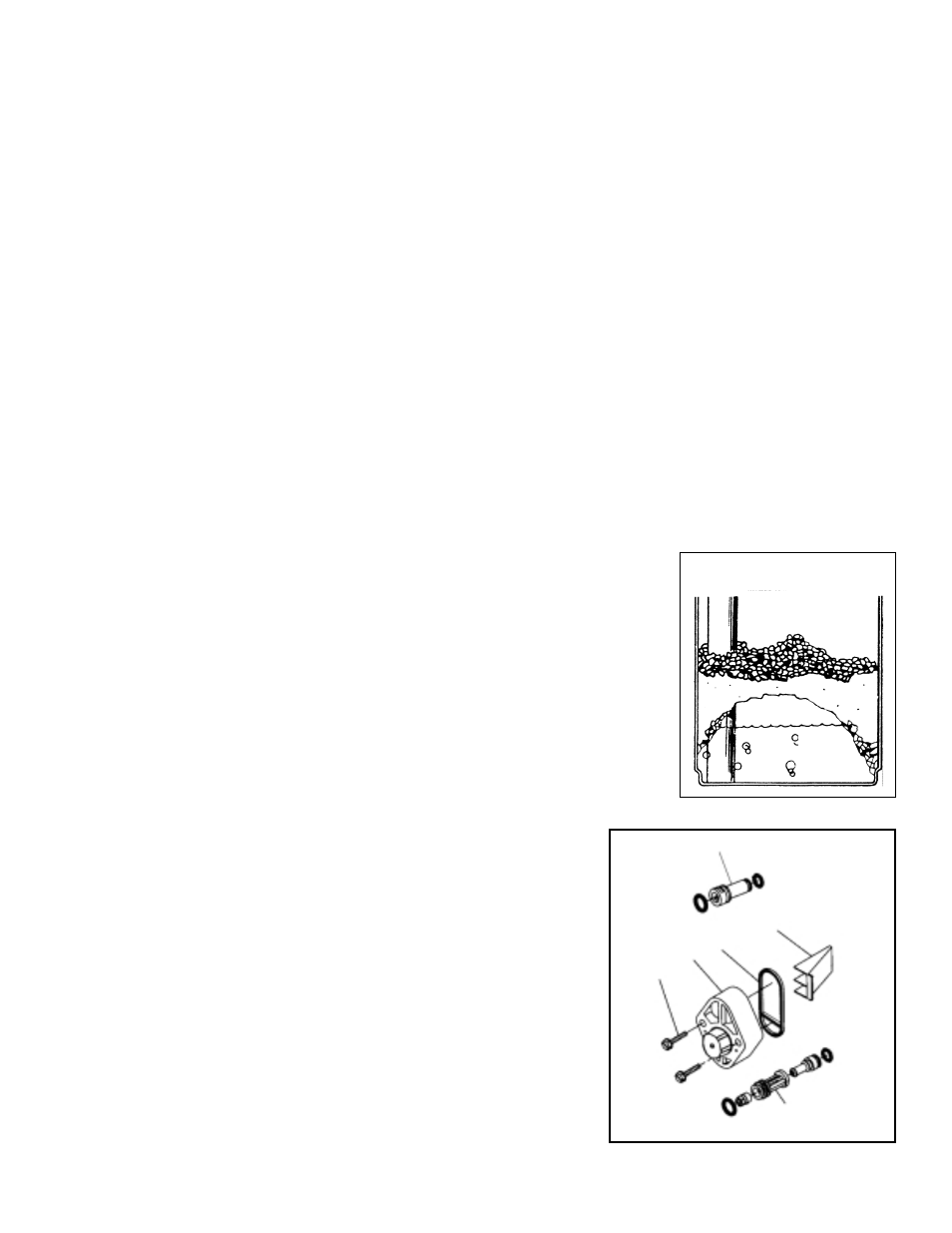

Bridging (Figure 6)

Humidity or the wrong type of salt may create a cavity between the water and the salt.

This action, known as “bridging”, prevents the brine solution from being made, leading to

your water supply being hard.

If you suspect salt bridging, carefully pound on the outside of the plastic brine tank or

pour some warm water over the salt to break up the bridge. This should always be

followed up by allowing the unit to use up any remaining salt and then thoroughly

cleaning out the brine tank. Allow four hours to produce a brine solution, then manually

regenerate the softener.

Cleaning the Injector Assembly (Figure 7)

Sediment, salt and silt will restrict or clog the injector. A clean water supply and pure salt

will prevent this from happening.

The injector assembly is located on the left side of the control valve. This assembly is

easy to clean.

Shut off the water supply to your softener and reduce the pressure by

opening a cold soft water faucet. Using a screwdriver, remove the two screws

holding the injector cover to the control valve body. Carefully remove the

assembly and disassemble as shown in Figure 7. The injector orifice is

removed from the valve body by carefully turning it out with a screwdriver.

Remove the injector throat the same way. Carefully flush all parts including

the screen. Use a mild acid such as vinegar or Pro-Rust Out to clean the

small holes in the orifice and throat.

Reassemble using the reverse procedure.

NOTE: The injector cover contains a factory set pressure regulator. Do not

attempt to adjust this regulator.

11

Injector Plug

Injector Throat/

Nozzle Assembly

Screen

O-ring

Screws

Injector

Cover

Figure 7

Figure 6