Typical installations – Hydrotech 5600 SXT Valve Chem Free Iron Filter Operation Manual User Manual

Page 8

6

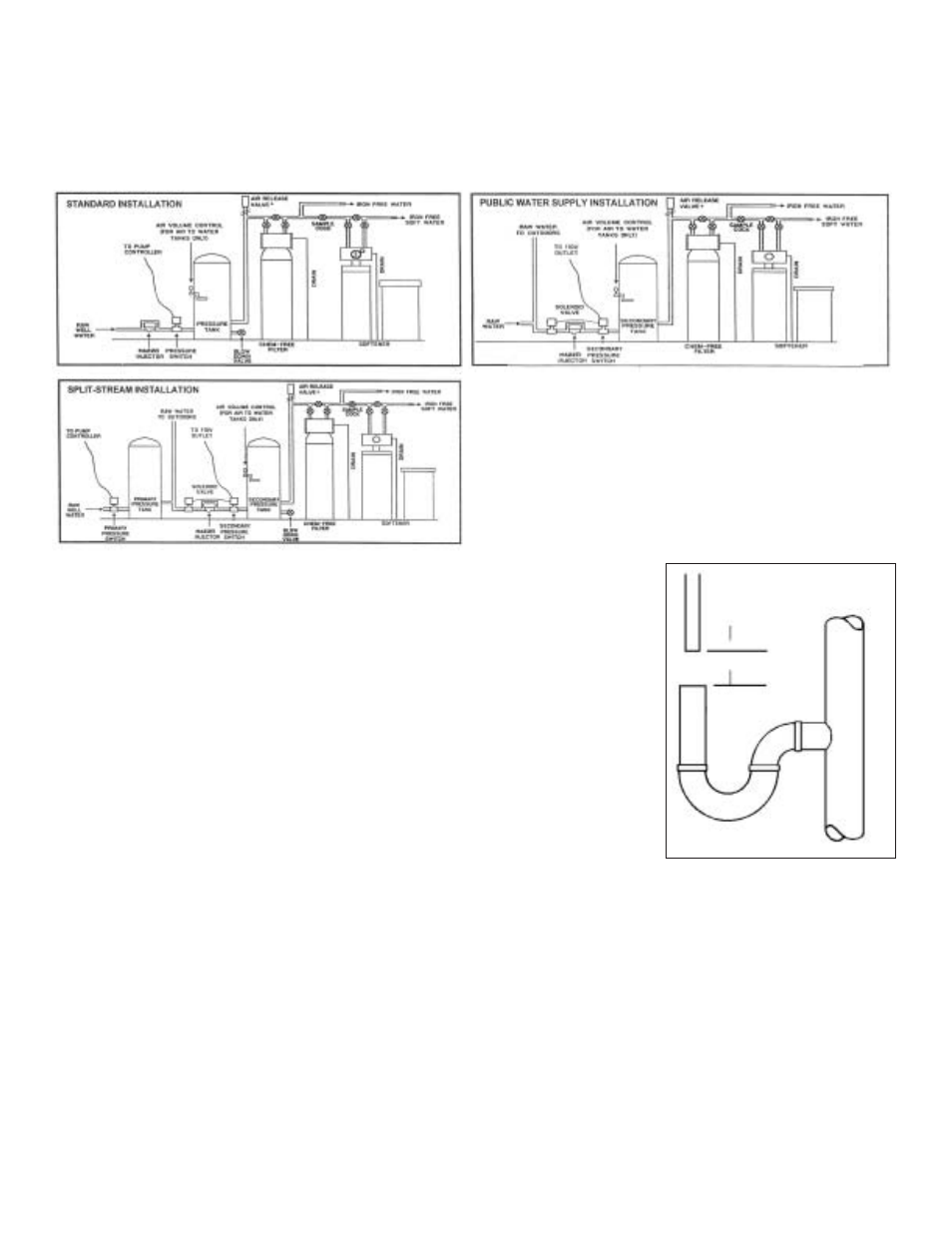

Typical Installations

Proper installation sequence of water conditioning equipment is very important. Refer to the following diagrams for your

particular water supply.

NOTE: Before starting installation, read Page 9, Plumbing System Clean-Up, for instructions on some procedures that

may need to be performed first.

1.

Shut off all water at main supply. On a private well system, turn off power to

pump and drain pressure tank. Make certain pressure is relieved from complete

system by opening nearest faucet to drain the system. Shut off fuel supply to

water heater.

2.

Cut main supply line as required to fit Mazzei injector in plumbing between well

pump and pressure tank (Mazzei injector may installed in a vertical or horizontal

position). Use teflon tape to join supply line to mazzei. DO NOT OVER TIGHTEN

fitiings, 25 ft Lbs Max. Be certain direction of flow arrow on the Mazzei injector

points toward pressure tank and pressure control switch is located on the

pressure tank side of the Mazzei injector (rapid cycling of the pump may occur if

pressure switch is located on the well side). If check valves are used, they should

be installed before the Mazzei injector, not between the Mazzei injector and the

pressure tank.

NOTE: It is advisable to install the Mazzei injector with the unions at both ends to

facilitate removal and inspection. On badly scaled older pumping systems, it may

be advantageous to install an optional "y" strainer ahead of the Mazzei injector to

prevent plugging the injector nozzle with scale.

3.

Cut the main supply line as required to fit plumbing to the control valve with bypass.

4.

Solder or solvent weld plumbing. Do not apply heat to any fitting connected to the control valve as damage may

result to the internal parts. Check to be certain water supply pipe is connected to the control valve inlet fitting and

pipe connected to control valve outlet fitting is in direction of house service.

NOTE: If the installation is to be split-streamed prior to the filter tank or is a public water supply installation, refer to

special instructions.

5.

Pull out drain line flow control assembly from valve body. Unscrew drain line fitting elbow from drain line flow control.

Apply Teflon tape to threads. Reassemble to valve body, making certain drain line flow control assembly is fully

inserted into valve body. Attach 1/2 in diameter drain line to drain elbow.

6.

Position drain hose over drain and secure firmly. To prevent back-siphoning of sewer water, provide an air gap of at

least 2 inches or 2 pipe diameters between the end of the drain hose and the drain. Do not raise drain hose more

than 10 ft. above floor.

Equipment

Drain Line

Air Gap

Drain

2”

Figure 3