Installation instructions, Figure 2 figure 1 – Hydrotech 5600 SXT Valve Chem Free Iron Filter Operation Manual User Manual

Page 7

5

Facts to Remember When Planning Your Installation

1.

All installation procedures must conform to local and state plumbing codes.

2.

All water must pass through the Mazzei injector, pressure tank and the filter or refer to the special instructions for a

split-stream installation. (System may malfunction if this instruction is ignored.)

3.

If water for other devices/activities, such as lawn sprinkling, a swimming pool, geothermal heating/ cooling is to be

treated by the filter, a larger model filter must be selected to accommodate the higher flow rate demands of these

items. The pumping rate of the well pump must be sufficient to accommodate these items plus the backwashing

requirement of the filter. Consult your dealer for alternative instructions if the pumping rate is insufficient.

4.

Remember that the filter inlet is attached to the pipe that supplies water and the outlet is the line that runs toward

the water heater.

5.

Before commencing installation, it is advisable to study the existing piping system and to determine the size, number

and type of fittings required. Typical system schematics shown in these instructions will be of assistance.

NOTE: If the plumbing system is used as the ground leg of the electric supply, continuity should be maintained by

installing ground straps around any non-conductive plastic piping used in the installation.

Installation Instructions

All government codes and regulations governing the installation of these devices must be observed.

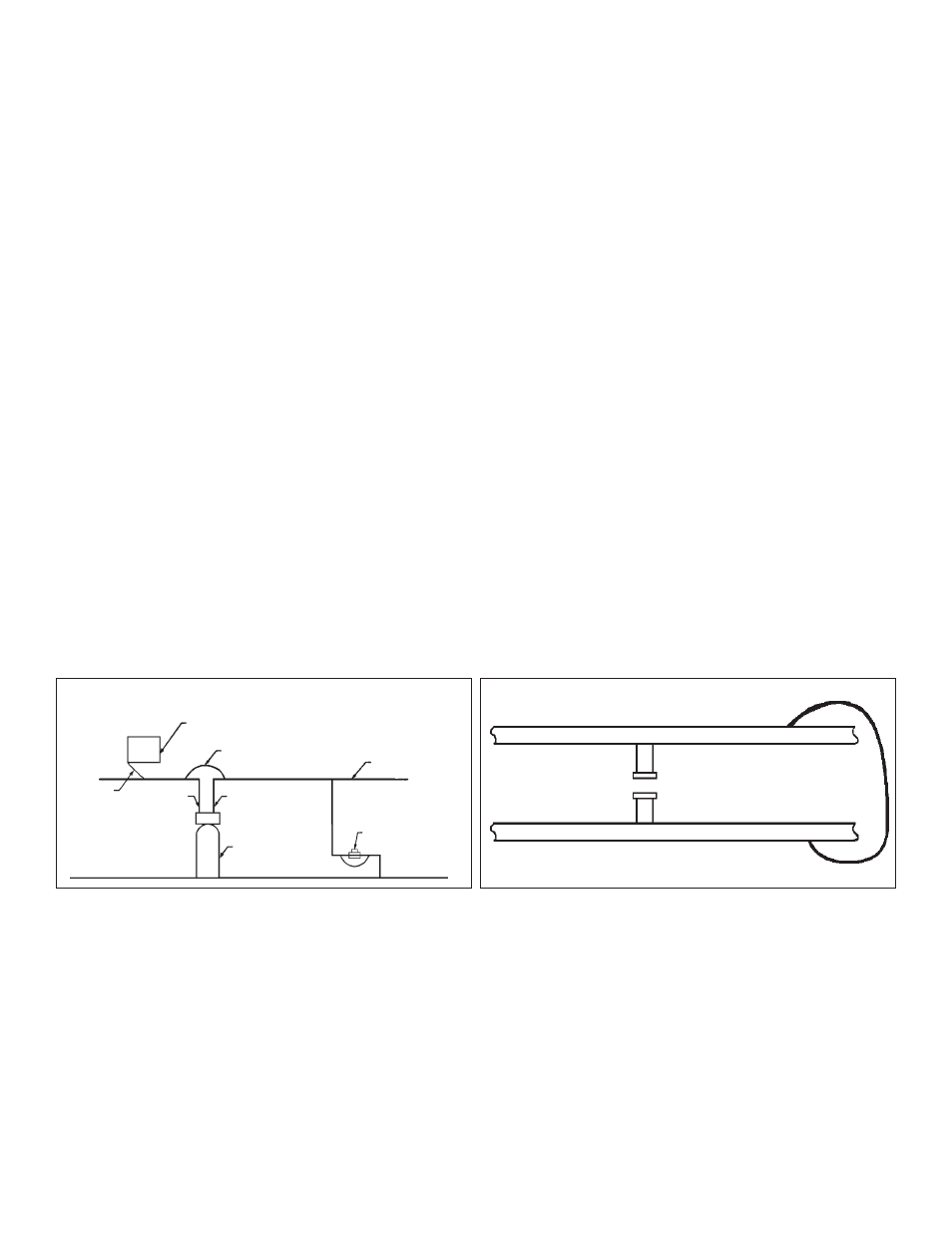

CAUTION: If the ground from the electrical panel or breaker box to the water meter or underground copper pipe is tied

to the copper water lines and these lines are cut during installation of the Noryl bypass valve and/or poly pipe, an

approved grounding strap must be used between the two lines that have been cut in order to maintain continuity. The

length of the grounding strap will depend upon the number of units being installed and/or the amount of copper pipe

being replaced with poly. See Figure 1.

In all cases where metal pipe was originally used and is later interrupted by poly pipe or the Noryl bypass valve as in

Figure 1 or by physical separation as in Figure 2, an approved ground clamp with no less than #6 copper conductor must

be used for continuity, to maintain proper metallic pipe bonding.

Check your local electrical code for the correct clamp and cable size.

Media Installation (When Necessary)

•

Remove the valve from the mineral tank.

•

Temporarily plug the open end of the riser tube to ensure that no resin or gravel falls down into the distribution.

•

Fill mineral tank one quarter full of water to protect distribution during gravel installation.

•

Slowly and carefully add the gravel support bed and the softener or filtration media leveling each layer as it is

placed into the tank.

•

Unplug the riser tube, carefully position the valve over it and turn the valve into the threads in the fiberglass

tank, tightening securely into tank. Note: Ensure that the internal O-ring in the valve fits securely over the riser

tube. Silicone grease (#13691) or other food grade lubricant may be applied to the O-ring to ease installation of

the riser tube. DO NOT use petroleum based lubricants as they will cause swelling of O-ring seals.

•

The softener or filter is now charged with softening resin.

•

It is recommended that the softener or filter tank now be completely filled with water (SLOWLY) to soak the resin

or filtration media before startup. This will allow the media to absorb water as well as help displace any trapped

air. This will reduce the chance of backwashing resin or filter media out of the tank during the initial backwash

on startup.

Figure 2

Figure 1

Electrical Panel

Ground Strap

Poly Pipe

Ground

From

Panel

Poly Pipe

Filter

c/w Plastic Bypass

Copper Pipe

Water Meter

Outside Water Line For Outside & 3rd Tap Comes From Meter

Filtered Water Line in Home

Unfiltered Water Bypass

Loop Cut & Capped

Ground Strap Required

Because of Break in Continuity