Generator installation, Igniting pilot burner, Control diagram – Green Air Products CO2 Generator User Manual

Page 2: Exhaust syncronized operation, Natural gas hook-up, Propane hook-up

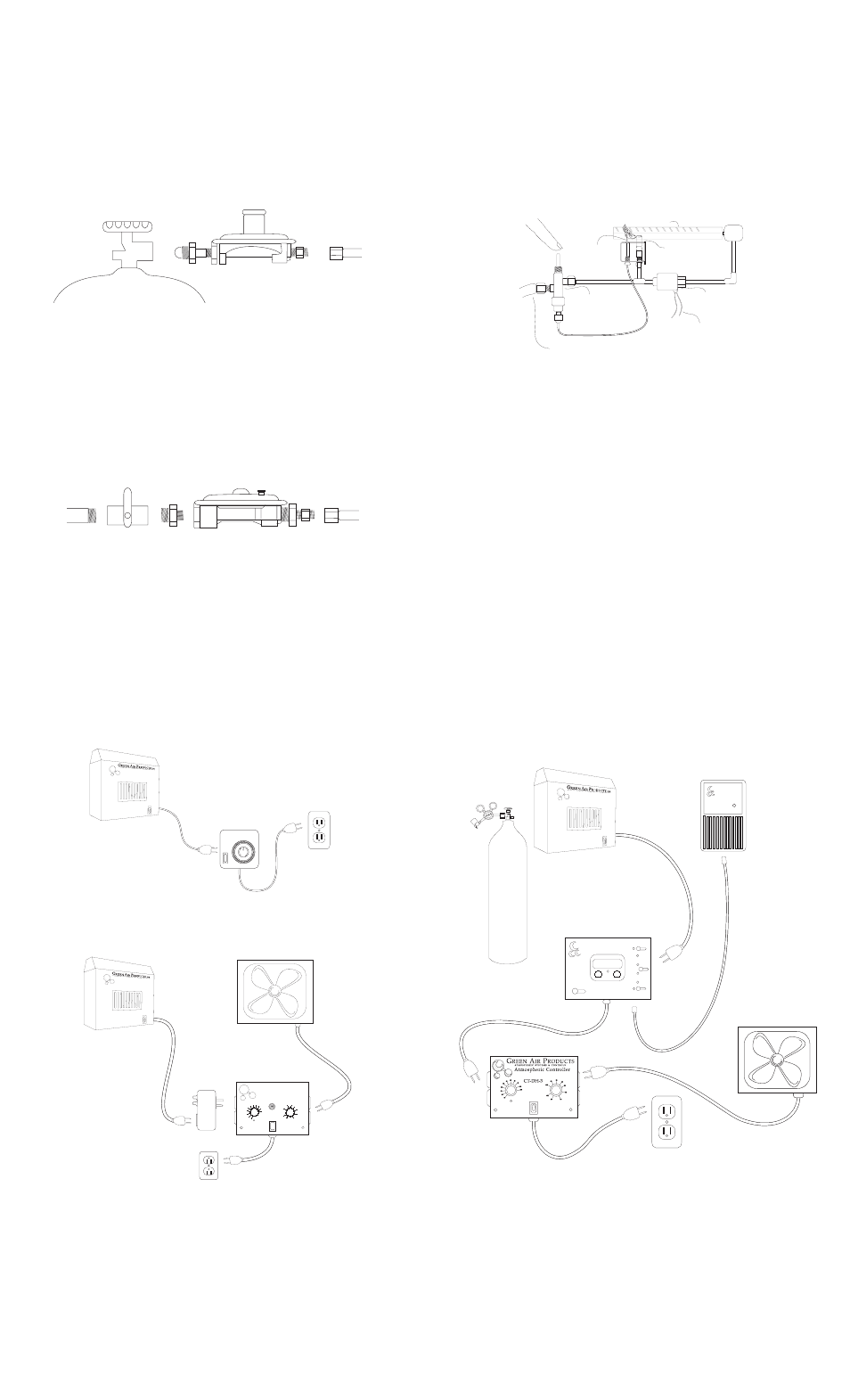

Generator Installation

1. Turn gas supply off before you begin work. Now connect a gas shut off

valve (not included) onto your incoming gas supply line. If needed reduce to

1/2 male nipple to accept enclosed regulator. Note gas flow direction indicator

arrow. Use gas compatible pipe compound on all pipe thread fittings and

tighten securely.

2. Connect regulator to shut off valve nipple with compound and tighten.

3. Check for gas leaks. A solution of 25% hand dish soap and 75% water in a

spray bottle will work well detecting gas leaks. Apply solution to all previously

connected fittings. Bubbles will occur around loose connections. Always use

two wrenches when tightening gas fittings.

Generator

hose

Regulator Assembly

Reducer

Nipple

Shut Off

Valve

Gas Supply

Line

Natural Gas Hook-up

Generator

hose

Regulator Assembly

Propane

Gas Tank

1. For propane applications use a propane tank that has been filled to only

80% of it’s capacity. This is very important for all propane burning mechanisms.

Failure to observe this common rule will make your generator hard to ignite

and will not stay lit (refer to troubleshooting).

2. Carefully thread the regulator flange nut in the tank valve counterclockwise

with your fingers until you feel the flange seat. Tighten firmly with adjustable

end wrench. DO NOT USE PLIERS! Fasten hose between regulator and

generator gas inlet in same fashion.

3. Turn the propane tank valve to wide open “ON” position.

4. Check for gas leaks. A solution of 25% hand dish soap and 75% water in

a spray bottle will work well for detecting gas leaks. Apply solution to all

previously connected fittings. Bubbles will occur around loose connections.

Always use two wrenches when tightening multiple fittings.

Propane Hook-up

WALL MOUNT

Bracket wall mount screw holes must be 10 inches center to center. Mount

brackets to wall and housing will slip over screw heads and fit snug into

slotted holes in housing back. This allows for easy removal of housing from

wall brackets. Make certain bracket screws are secure in wall and use good

judgement when choosing mounting location.

SUSPENDED

Use chain, eyebolts and ceiling hooks found in hardware pack. Hang unit

from sturdy location at least 18 inches from ceiling. The unit must operate in

level upright position. “CAUTION” Should unit fall during operation fire may result.

FREE STANDING

Remove the four screws holding the bottom plate to the housing. Locate the

holes on the bracket to match and replace the screws.

Igniting Pilot Burner

1. Plug the transformer into a grounded 110 volt timer or other power source.

2. Depress the RED button located on the inside of the generator for 90 seconds

to clear the air from the hose.

3. Once gas is present at the pilot let up button and wait 60 seconds for

excess gas to clear from the housing. Now depress the RED button again

and light the pilot burner. Maintain holding the button down for an additional

30 seconds to allow the thermocouple to heat to operating temperature.

4. Push the front on-off switch to the “ON position. Fuel will pass through the

solenoid valve and the main burner will be ignited by the pilot flame. As your

timer cycles on and off so will the main burner flame.

5. For the CD-18 and CD-36 , the brass needle valve may be used to very the

flame size. This will increase or decrease the time that the unit needs to

charge the area with CO2. The specs are based on the valve being fully open.

Junker Valve

Solenoid Valve

Burner

Pilot Light

Thermocouple

To solenoid valve

"On" "Off" switch

Gas feed hose from

regulator

Control Diagram

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

24 Hr.

Clock Timer

This example shows the simplest method of CO

2

generator control. Set the

Green Air ProductsTimestat, Cyclestat or PDT-1 timer for short intervals

during light hours only.

G

REEN

A

IR

P

RODUCTS

P R O F E S S I O N A L G R E E N H O U S E E Q U I P M E N T

CT-DH-3P

AtmosphericControlle

110

100

90

80

10

70

20

30

40

50

60

50

4

0

OFF

30

20

ON

60

70

80

This system is the ultimate in precise automated CO2 control. The CDM-6000

sensor continuously determines atmospheric CO2 values. The CDDS-2

controller interprets these values and provides flexible set point adjustments

to sequence CO2 equipment functions. The CDDS-1 has a built in photo

sensor to disable CO2 production during darkness. The CDMC-2 system can

be combined with the CT-DH-3 temperature and humidity controller to defeat

CO2 production during exhaust functions. The CO2 generator (or emitter

system) and the monitor are plugged into the CDDS-2 controller. CDDS-2

controller and the fan are plugged into the CT-DH-3 as shown. Plug the

power cord from the CDDS-2 controller into the left hand equipment outlet

on the CT-DH-3. The power to the sequencer will be interrupted when ever

the temperature or humidity conditions constitute an exhaust function. CO2

production will resume immediately after exhaust cycle is completed. Co2

levels will be maintained precisely and automatically. Order the CDMC-6 for

this Carbon Dioxide Monitor Controller combination.

Exhaust Syncronized Operation

This diagram demonstrates an exhaust synchronized system where the CO2

equipment is disabled during exhaust functions and immediately replenished

when exhaust is completed. The CT-DH-3P temperature and humidity

controller activates the exhaust fan and shuts off the CO2 during the exhaust

cycle. It has a built in photo sensor to limit CO2 enrichment to photoperiods

only. Enrichment will only occur when exhaust fan is off and light is present.The

CO2 “On” cycles are timed by the Cyclestat repeat cycle timer which cycles

the CO2 equipment according to your preset periods. An example might be

that the timer is set for 5 minutes every hour. The CO2 generator would be

operated according to that hour schedule. In the event that there is an exhaust

function at any time the CO2 will come on for 5 minutes immediately after the

exhaust cycle is completed. It will repeat again one hour after that point.

Replenishment of CO2 will always follow an exhaust cycle to maintain a

constant and continuous enrichment level.

PILOT LIGHT FAILS TO IGNITE:

Make sure propane tank has fuel and valve is fully open. For natural gas

generators make sure gas supply is "On" and shut off valve is open. Make

sure propane tank has not been overfilled. If so, take tank outdoors and open

valve to release gas for a few seconds and reconnect. Remember red button

must be depressed to light pilot.

PILOT LIGHT WON’T STAY LIT:

Hold the red button down to clear all pockets of air from inside the hose. Make

sure the propane tank has not been overfilled. If so, take tank outdoors and

open valve to release gas for a few seconds and reconnect. Remember, red

button must be depressed for 30 seconds or until the thermocouple heats to

operating temperature and holds pilot open.

BURNER FAILS TO IGNITE:

Check that the tank valve is fully open. Be sure all air has bled from the hose

and gas is present. Make sure the transformer is plugged into a working power

source. Make sure power indicator switch is in “ON” position. Check that

needle valve is open.

BURNER WON’T STAY LIT:

Check that needle valve is open enough to support a strong minimum flame.

Check timer and power source operation.

FLAME BURNS IRREGULAR:

Dirt or residue could constrict burner orifice. Low fuel pressure due to depleted

or contaminated fuel supply. Lack of oxygen content in room due to inadequate

fresh air intake. Excessive air movement or gust from fan or ventilation.

Generator not setting level.

Trouble Shooting Tips (see www.greenair.com for further information)