Brooks Instrument 2540-I User Manual

Brooks, 2540 flowmeters

Installation and Operation Manual

X-VA 2540-eng

Part Number: 541B166AAG

May, 2011

Brooks

®

2540 Flowmeters

Brooks

®

Model 2540

Acrylic block flowmeters are available in various ranges

in both SAE and SI units for air and water (see chart on

other side). These direct reading meters are also

available for other gases and liquids. If the meter will be

used with fluids other that air or water, please consult

chemical compatibility data for possible effects on the

meter. When properly installed and maintained, these

durable acrylic

UNPACKING

Precautions have been taken to prevent any damage

from occurring during shipment. However, if the meter

is received damaged, report it to the carrier

immediately. Before installing, verify that you have the

model and flow range required.

ACHIEVING ACCURATE FLOWRATES

To obtain an accurate flowrate, the float must be read at

the position indicated on the meter. Additionally, the

flowmeter should be installed in a manner, which

minimizes both external vibrations and internal flow

variations. Special care should be taken so that the

connections to the meter's inlet and outlet fittings do not

overly restrict the liquid or gas flow being metered. This

could result in a reduced flow volume, preventing the

meter from reaching its maximum flowrate.

Furthermore, internal pressures could be affected,

which can cause inaccurate flow readings. On start-up,

slowly purge any fluid trapped in the meter.

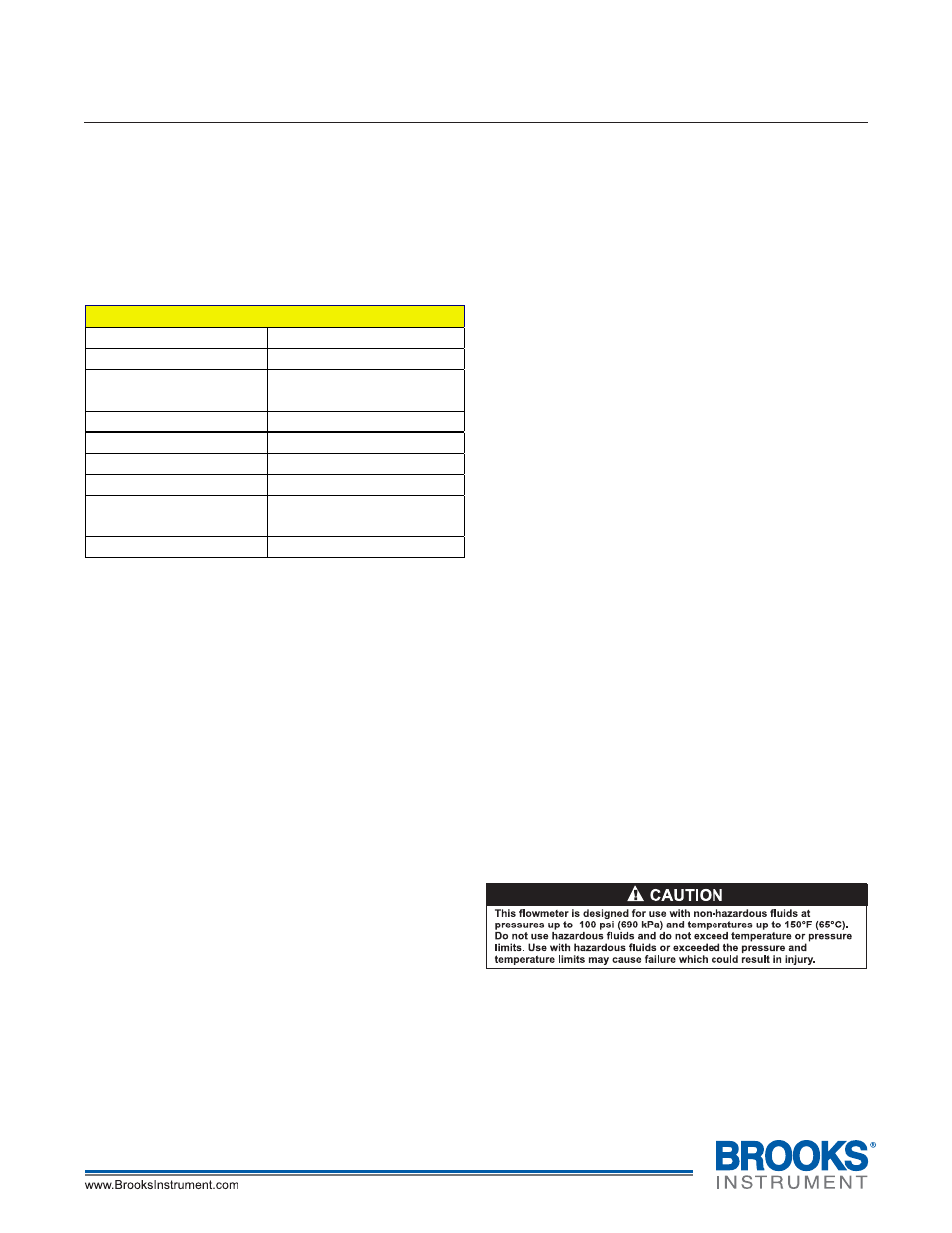

SPECIFICATIONS

ACCURACY:

± 2% Full Scale

FLOATS:

Stainless Steel

WETTED METAL

PARTS:

Stainless Steel

METER BODY:

Clear Acrylic

FITTINGS:

1-11 1/2 FNPT PVC Fittings

ELASTOMERS:

Buna-N

MOUNTING INSERTS:

10-32 UNF

MAXIMUM

TEMPERATURE:

150°F (65 °C)

MAXIMUM PRESSURE: 100 PSI (690 kPa)

INSTALLATION

These meters are supplied with round 1-11 ½ FNPT

inlet and outlet fittings. When installing the meter,

securely hold the meter's fittings from rotating while

connecting the flow lines. (Use pipe thread sealant or

Teflon

®

tape to achieve a positive seal when connecting

the flowmeter.) Failure to hold the meter fittings or

over-tightening may cause damage to the fitting,

flowmeter or both; which will result in leaks or meter

failure. The meter is supplied with #10-32 threaded

inserts for mounting. When installing, use slotted

screws and torque to a maximum of 35 in-lbs. Mounting

dimensions are shown in Figure 1.

CLEANING AND DISASSEMBLY

Occasional cleaning may be required if dirt appears in

the flow tube or if float movement becomes restricted.

To clean, remove the top plug (standard back) or the

outlet fitting (inline) and remove the rod guide

assembly. Wash the tapered hole, float stops and top

plug with a mild liquid detergent and soft brush. Rinse

all parts with clean water and dry thoroughly with clean

air or nitrogen. Do not use solvents to clean this meter

as they will attack the acrylic and destroy the meter

REASSEMBLY

Check to make sure that all parts are clean and dry. To

lubricate the O-rings, apply a small amount of

halocarbon grease prior to reassembly. Replace the

float on the rod guide and reinstall the float stops.

Reinstall the rod guide assembly into the flowmeter

body. Make sure the rod guide is seated firmly in the

body of the meter for a Standard Back meter or in the

inlet fitting of the Inline meter. (For meters with valves,

it will be necessary for the rod guide to pass through the

slot in the valve tip.) To allow proper use of the valve,

do not tighten the valve tip completely on the valve

stem. Reinstall the top plug or the outlet fitting, making

sure that the rod guide is properly aligned.