Installation and operation manual – Brooks Instrument Control Valve User Manual

Page 5

1-1

Section 1 Introduction

Installation and Operation Manual

X-VA-8503-eng

Part Number: 541B087AHG

March, 2008

Needle Control Valves Models 8503 and 8504

1-1 Description

Brooks

®

NRS (Non-Rising Stem) Needle Valves are designed specifically for

low flow gas and liquid applications. Straight and angle pattern models in

Brass or Stainless Steel are available. Five different interchangeable

connection fittings can be used with each.

Models 8503 & 8504 are supplied with an NRS control valve. It features a

positive, direct mechanical means of adjusting a sliding tapered needle

which virtually prevents sticking due to foreign matter in the fluid stream.

These valves are particularly suitable for the precise control requirements in

chromatography. The flow is constant for any given stem position. Saw-

toothing is eliminated. Six needles with different tapers provide a wide choice

of flow ranges for all models. Each increases capacity by an appropriate

factor of three. Needles and orifices can be changed without removing the

valve from the line. (Two different orificies are used - one for needle sizes 1-3,

another for size 4-6.)

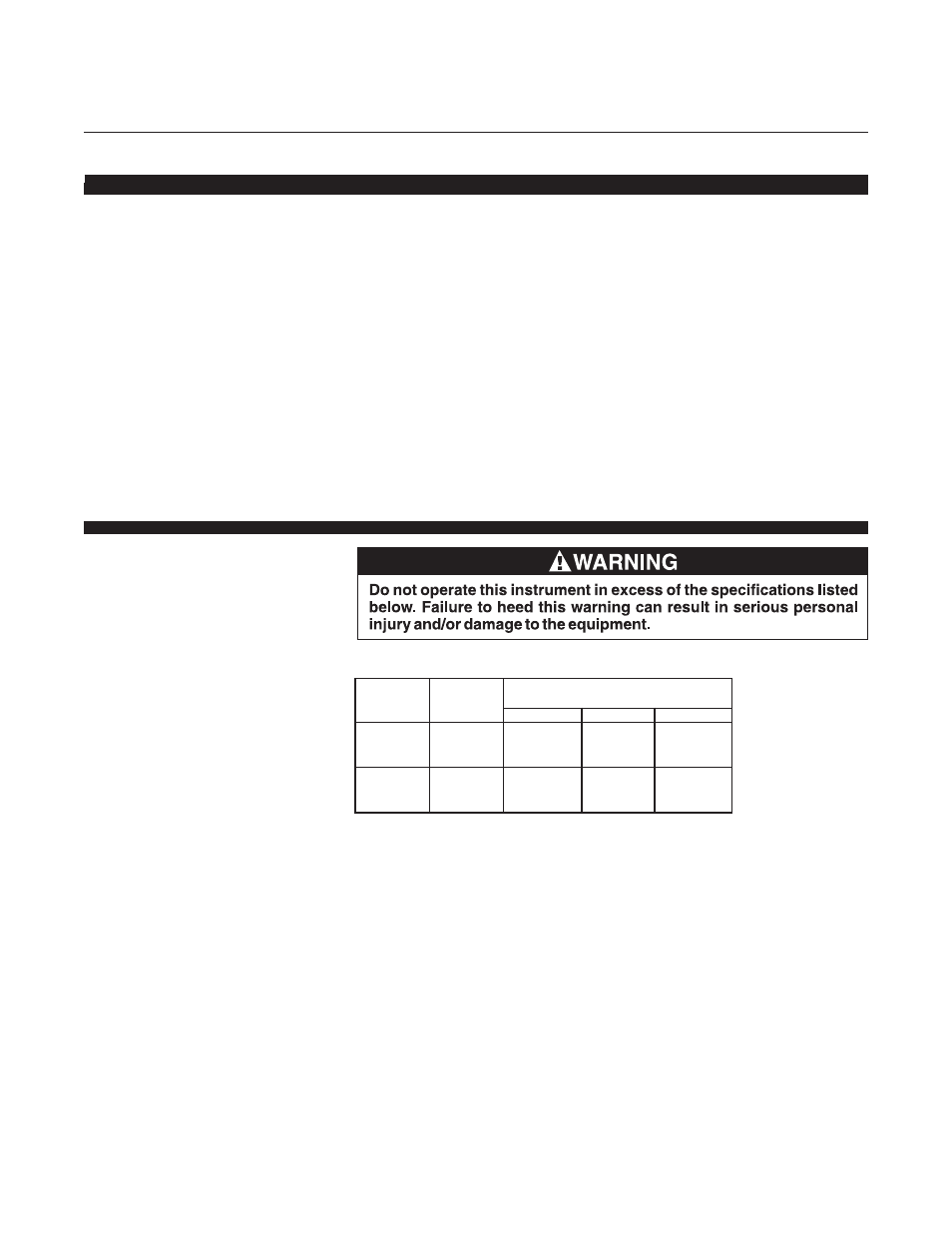

1-2 Specifications

Capacities and Pressure Drops

Maximum Operating Pressure

Brass Model: 600 psig

Stainless Steel Model: 1000 psig

Maximum Operating Temperature

Brass Model: 180°F

Stainless Steel Model: 250°F

Connections

Standard: 1/8" Female NPT - Integral

Optional: 1/8", 1/4" compression fitting; 1/4" female NPT; 1/4" ID hose type

adaptors

Dimensions

Refer to Figure 1-1

Maximum Capacity

Needle

Orifice

(Std. cc/min.)

Taper No.

Type

Helium

Air

Water

1

300

150

4

2

Small

700

350

10

3

(0.041")

1,400

600

20

4

6,000

2,400

80

5

Larger

18,000

6,800

200

6

(0.093")

55,000

22,000

650

Capacities measured with 10 psig supply and an atmospheric

pressure exhaust. Flow capacities will vary for different gases,

liquids and pressures. Consult factory for further information.