Troubleshooting, Examples – Flowline LC8X Thermo-Flo User Manual

Page 6

Step Eight

Step Nine

TROUBLESHOOTING

Controller Logic:

For all controllers, please use the following guide

to understand the operation of the Flowline LC80/LC82 controllers.

1. Make sure the Green power LED is On when power is supplied to

the controller.

2. For NC switch wiring, the input LED's on the controllers will be

Amber when the switch reads no-flow and Off when the switch

reads flow.

3. The input LED will always respond to its corresponding relay

LED. With invert Off (-), the relay LED will be On when the input

LED is On and Off when the input LED is Off. With invert On (+),

the relay LED will be Off when the input LED is On and On when

the input LED is Off.

4. The relay may be wired either NO or NC. The normal state of the

relay is when its LED is Off. With the LED On, the relay is in the

energized mode and all terminal connections are reversed.

5. LC82 model only, Latch ON operation: When both input LED's

are ON, the relay will be energized (red LED On). After that, if

one switch input turns Off, the relay will remain energized. Only

when both switch LED's are Off will the controller de-energize

the relay. The relay will not energize again until both switch

LED's are ON. Reversing Invert switch will reverse logic. See the

Logic Chart below for further explanation.

Set Points:

If the preset factory calibration is not adequate for

your application, follow the calibration steps listed below. Note: the

switch's internal LED will be on when the switch detects no-flow and

will off when the switch detects flow.

1. Install the fitting and flow switch as described in the Installation

section of this manual. Turn the flow switch and controller power

on and adjust the flow rate to the application setting. If the medi-

um to be sensed is likely to be subject to high temperature varia-

tions, the flow switch should be set at the highest normal temper-

ature likely to be encountered.

2. Locate the potentiometer knob at the top of the flow switch. The

red LED is visible through the potentiometer. (If the LED is on,

slowly adjust the potentiometer counterclockwise, with a small

flat head screwdriver until the LED turns off.) The adjustment is

a single turn 270° potentiometer. The initial response time of the

flow switch after adjustment is 1 to 10 seconds. Adjust the poten-

tiometer in slow increments and wait for the response.

If the LED is off, slowly adjust the potentiometer clockwise until

the light turns on. Then turn the potentiometer counterclockwise

to bring the LED off at a reliable setting. Remember, adjust the

potentiometer in slow increments and wait for the response.

3. Verify that the new calibration is correct by lowering the system

flow rate below the set point and check to see that the red LED

turns on. Then increase the flow rate above the set point and ver-

ify that the red LED turns off accordingly.

Liquid Switch

Gas Switch

FT10-___5 Series

GT10-___5 Series

EXAMPLES

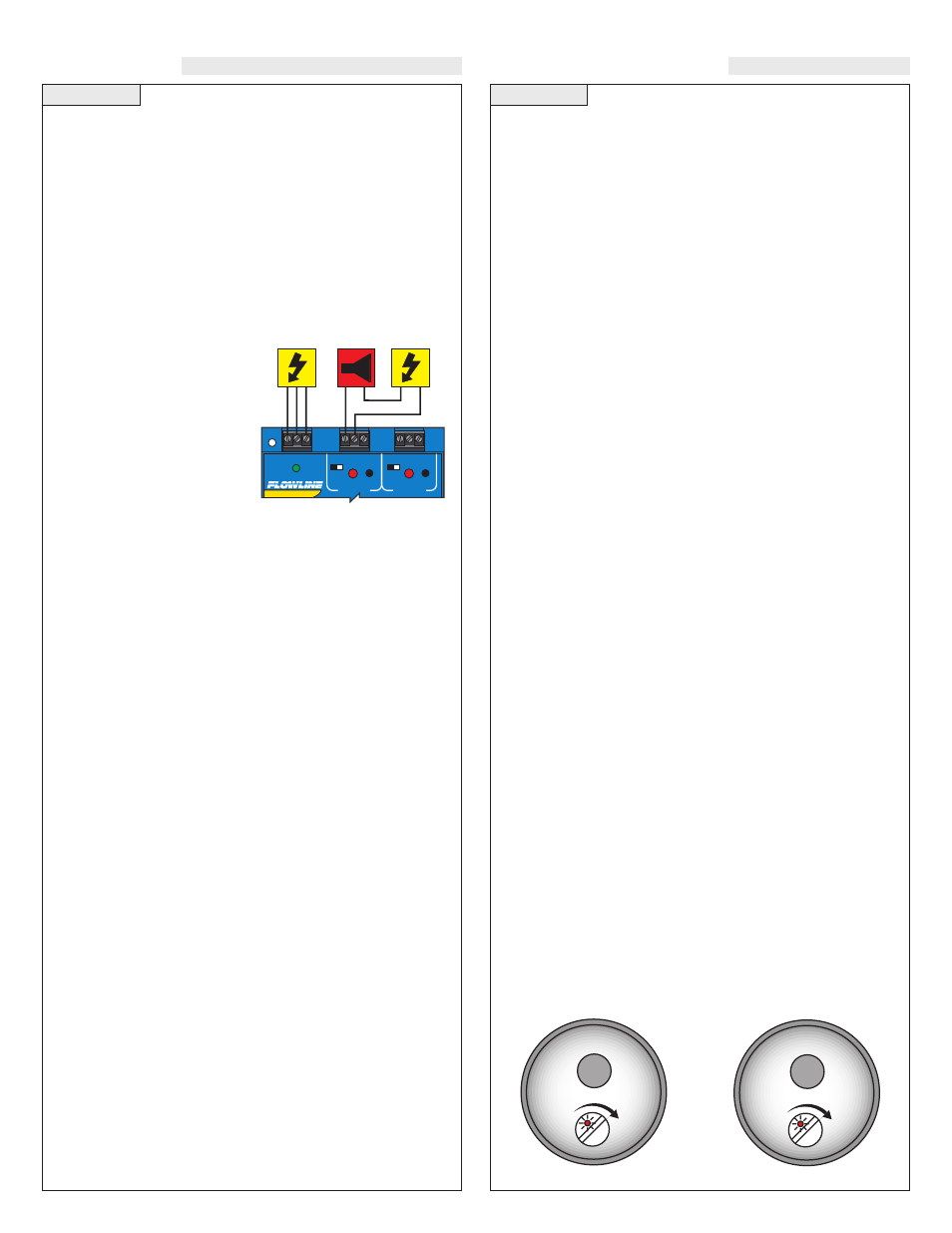

Low Flow Alarm:

The goal is to indicate when the flow rate falls

below a certain point. If it does, an alarm is supposed to sound, alert-

ing the operator of a low flow condition.

If power is accidentally cut to the controller, the sensor's ability to

notify the operator of a low flow condition could be lost. The system

must alert the operator not only to low flow, but to controller power

loss. To do this, connect the hot lead of the alarm to the NC side of

the relay terminal of the controller. If power is lost, the relay will be

de-energized, and the alarm will sound (if there is still power to the

alarm circuit itself). The alarm circuit should have a non-interruptible

power supply or some other indicator or backup alarm to warn of a

power failure in the alarm circuit.

In this application, the normal status

is when the sensor is in the flow con-

dition, and the relay will be energized

holding the alarm circuit open. If the

switch is wired NC, the input LED

will be off and the relay LED will

be on. So for this application,

Invert should be set to the On posi-

tion. If the switch is wired NO, the

input LED and the relay LED will

be on simultaneously . So for this appli-

cation, Invert should be set to the Off (-) position.

R E L A Y 1

R E L A Y 2

P O W E R

- +

- +

I N V E R T

D E L A Y

I N V E R T

D E L A Y

Invert ON (+) setting

1 fps

90 fps

10 fps

.04 fps

3 fps

0.2 fps