Guide to controls installation – Flowline LC8X Thermo-Flo User Manual

Page 4

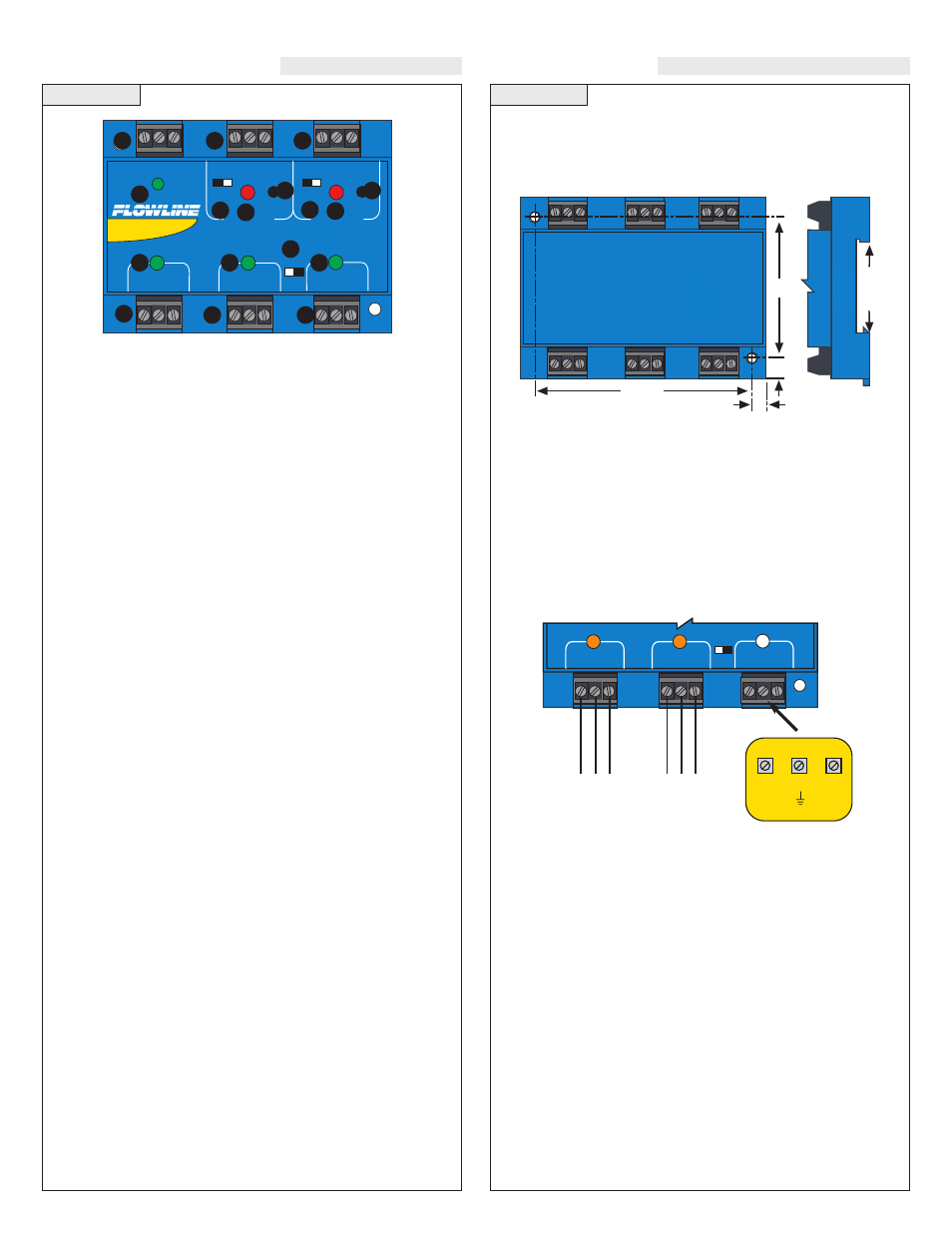

Step Four

Step Five

GUIDE TO CONTROLS

INSTALLATION

1. Power indicator:

This green LED lights when AC power is ON.

2. Relay indicator:

This red LED will light whenever the con-

troller energizes the relay, in response to the proper condition at

the switch input and after the time delay.

3. AC Power terminals:

Connection of 120 VAC power to the

controller. The setting may be changed to 240 VAC if desired.

This requires changing internal jumpers; this is covered in the

Installation section of the manual. Polarity (neutral and hot) does

not matter.

4. Relay terminals (NC, C, NO):

Connect the device you wish to

control (pump, alarm etc.) to these terminals: supply to the

Common (COM) terminal, and the device to the Normally Open

(NO) or Normally Closed (NC) terminal as required. The

switched device should be a noninductive load of not more than

10 amps; for reactive loads the current must be derated or protec-

tion circuits used. When the red LED is ON and the relay is in the

energized state, the NO terminal will be closed and the NC termi-

nal will be open.

5. Time delay:

Use potentiometer to set delay from 0.15 to 60 sec-

onds. Delay occurs during switch make and switch break.

6. Input indicators

: Use these LEDs for indicating Flow or No-

Flow status of switch. For NC wiring, an Amber LED indicates

No-Flow and no LED indicates Flow. For NO wiring, an Amber

LED indicates Flow and no LED indicates No-Flow.

7. Invert switch:

This switch reverses the logic of the relay control

in response to the switch: conditions that used to energize the

relay will now de-energize the relay and vice versa.

8. Latch switch (LC82):

This switch determines how the relay

will be energized in response to the two sensor inputs. When

LATCH is OFF, the relay responds to switch Input 2A only; when

LATCH is ON, the relay will energize or de-energize only when

both switches (2A and 2B) are in the same condition (Flow or No-

Flow). The relay will remain latched until both switches change

conditions.

9. Input terminals:

Connect the switch wires to these terminals:

Note the polarity: (+) is a 24 VDC, 50 mA power supply (con-

nected to the red wire of a Flowline flow switch), and (-) is the

common ground path from the switch (connected to the black

wire). Also, the (S) is a 14 VDC, 25 mA supply (connected to the

white wire). If polarity between the red and black wires is

reversed, the switch will change from NC to NO.

Panel DIN Rail Mounting:

The controller may be mounted by either a back panel using two

screws through mounting holes located at the corners of the controller

or by snapping the controller on 35 mm DIN Rail.

Note:

Always install the controller in a location where it does not

come into contact with liquid.

Connecting N-channel Switches to Input Terminals:

Please note a difference between Flowline flow switches (N-channel,

P-channel and Relay). Use only the N-Channel or Relay switches

with the LC80 series of controller. Wire the Red wire to the (+) ter-

minal and the Black wire to the (-) terminal. Wire the White wire to

the (S). See the illustration below to indicate wiring for your switch.

Reversing Red and Black wire will change switch from NC to NO.

Note: connect the Shield wire on the Flow switch to the GND termi-

nal if required.

STANDARD

CONTROLLER

R E L A Y 1

R E L A Y 2

P O W E R

I N P U T 1

I N P U T 2 A

I N P U T 2 B

- +

- +

I N V E R T

D E L A Y

I N V E R T

D E L A Y

LATCH

ON OFF

1

3

7

2

5

4

4

7

2

5

6

8

6

6

9

9

9

I N P U T 1

I N P U T 2 A

I N P U T 2 B

LATCH

ON OFF

W

h

it

e

B

la

c

k

FT10-___2

GT10-___2

NC Wiring

R

e

d

W

h

it

e

R

e

d

FT10-___2

GT10-___2

NO Wiring

B

la

c

k

INPUT

24 VDC

100 mA

Max

( - )

S

( + )

14 VDC

25 mA

Max

3.475"

2.2"

.275"

.225"

3

5

m

m

D

IN

R

a

il