Installation electrical – Flowline LP50 Switch-Tek User Manual

Page 4

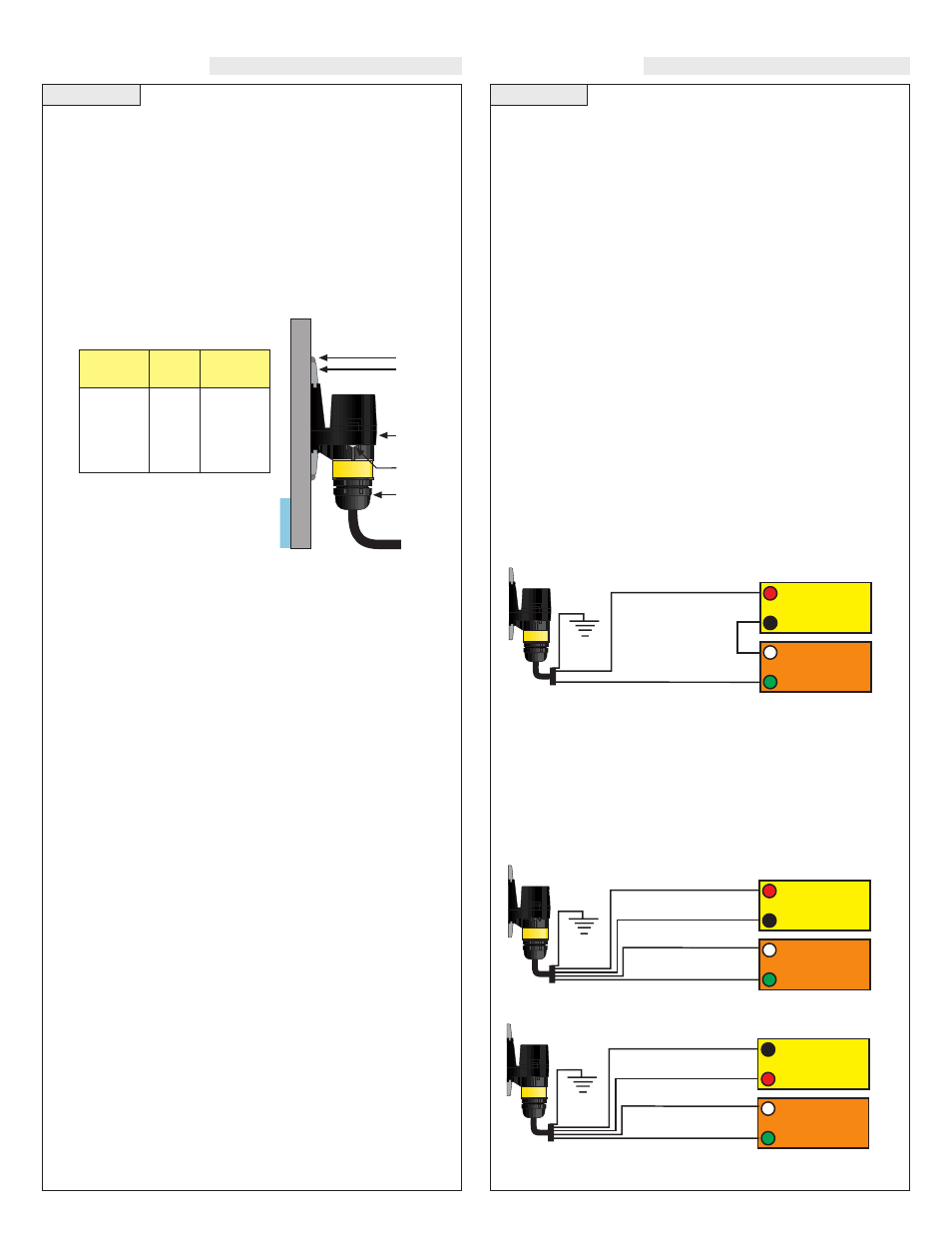

Step Four

Step Five

INSTALLATION

ELECTRICAL

FLOWLINE's LP50 series level switch may be installed anywhere on

a tank wall using the supplied PE, PP, or PVDF fitting that the switch

slides into. The fitting comes with adhesive on the tank side that is

sufficient to hold the sensor in position temporarily while the instal-

lation is tested, but for permanent installation the fitting must be

welded, glassed or strapped to the tank. Extra fittings are available

from Flowline, so that the level switch may be moved to different

locations on the tank by sliding it into other fittings.

Attach the fitting to the tank:

1. Determine whether the tank is PP, PE or PVDF. The slide-in fit-

ting shipped with the sensor is determined by the part number. If

necessary, obtain an additional fit-

ting.

2. Determine the mounting location

for the level switch. The point of

actuation (where the sensor will

send a “wet” signal) is most often

at the center of the sensor; however the actual Point of Actuation

(POA) may differ depending on the application liquid and tank

wall characteristics. After positioning the fitting to check clear-

ances, etc., remove the paper protective strips from the adhesive

of the fitting.

3. Press the fitting into place. The adhesive provides a seal between

the sensor and the tank wall, and will hold it in place during test-

ing and installation.

If desired, the sensor may be installed temporarily without weld-

ing the fitting to the wall. If several different locations must be

tried before permanent installation, use double-sided foam stick

tape designed for PP, PE or PVDF, for example Arclad type PE-

6024, CO#7331 (from Adhesive Research Inc., Glen Rock PA

17327) or equivalent.

4. After the sensor has been tested to verify the POA, weld, glass or

strap the fitting to the tank using standard industrial plastic tech-

niques.

Special note for small round tanks:

The fitting may be attached to small, round tanks, as long as the

majority of the fitting is firmly attached to the wall. However,

extreme installations may effect the switches performance.

Mount the sensor in the fitting:

1. Slide the sensor into the fitting.

2. After trimming the sensor wire to length if needed by the installa-

tion, thread the sensor wire into a plastic flexible conduit with a

1/2" male fitting. Screw the conduit into the sensor, being careful

not to cross the threads. Do not over tighten the conduit in the

sensor as this may break the fitting. Such damage is not covered

by the warranty. Take care while pulling the wire through conduit

that no excessive tension is placed on the sensor end of the wire,

so that the wire is not broken from the sensor housing.

3. Connect the sensor wire to the controller following the instruc-

tions in its manual. See the following Wiring Section for detailed

wiring instructions.

Signal Outputs (Relay switching):

Allows the sensor to switch a small load on or off directly, using an

internal 1 A relay (60 VAC/60 VDC). All models, LP50-_005, use

the relay and features 4 wires (red, black, white and green) and a

shield wire. The NO/NC status is set by the polarity of the voltage

feeding the Red and Black wires. The Green wire is the common for

the relay and the White is the NO or NC, depending on the polarity of

Red and Black.

Normally Open Wiring:

Supply Voltage:

The supply voltage to the Switch-Tek level switch should never exceed

a maximum of 36 VDC. Flowline controllers have a built-in 13.5 VDC

power supply which provides power to all of FLOWLINE's electrical-

ly powered sensors. Alternative controllers and power supplies, with a

minimum output of 12 VDC up to a maximum output of 36 VDC, may

also be used with the Switch-Tek level switch.

Required Cable Length:

Determine the length of cable required between the Switch-Tek level

switch and its point of termination. Allow enough slack to ensure the

easy installation, removal and/or maintenance of the sensor. The

cable length may be extended up to a maximum of 1000 feet, using a

well-insulated, 14 to 20 gauge shielded four conductor cable.

Wire Stripping:

Using a 10 gauge wire stripper, carefully remove the outer layer of

insulation from the last 1-1/4" of the sensor's cable. Unwrap and dis-

card the exposed foil shield from around the signal wires, leaving the

drain wire attached if desired. With a 20 gauge wire stripper, remove

the last 1/4" of the colored insulation from the signal wires.

Signal Outputs (Current sensing):

The standard method used by Flowline controllers; this technology uses

only two wires (Red and Black). The sensor draws 5 mA when it is dry,

and 19 mA when wet. NC/NO status must be set by the controller. The

Green and White wires are not used.

Multimeter

(mA)

Red

Black

Shield

Ground

24 VDC

Power Supply

+

-

-

+

Multimeter

(Continuity)

Red

Green

Shield

Ground

24 VDC

Power Supply

+

-

-

+

Black

White

Weld

Fitting

Sensor

1/2" NPT

Connector

Screw

Multimeter

(Continuity)

Black

Green

Shield

Ground

24 VDC

Power Supply

+

-

-

+

Red

White

Normally Open Wiring:

Switch

Bracket

Bracket

Part No.

Material

Part No.

LP50-1005

PP

LP95-1001

LP50-5005

PVDF

LP95-5001

LP50-6005

PE

LP95-6001