Specifications – Flowline LP50 Switch-Tek User Manual

Page 2

Step One

SPECIFICATIONS

Technology:

The non-intrusive RF capacitance switch detects the pres-

ence of liquid or air by measuring the conductive or dielec-

tric values which are present in all materials. An electrical

capacitor is formed between the level switch and the outer

tank wall. As liquid rises and falls against the inner wall, the

capacitance effect is greatly increased and the 1A SPST

relay changes state.

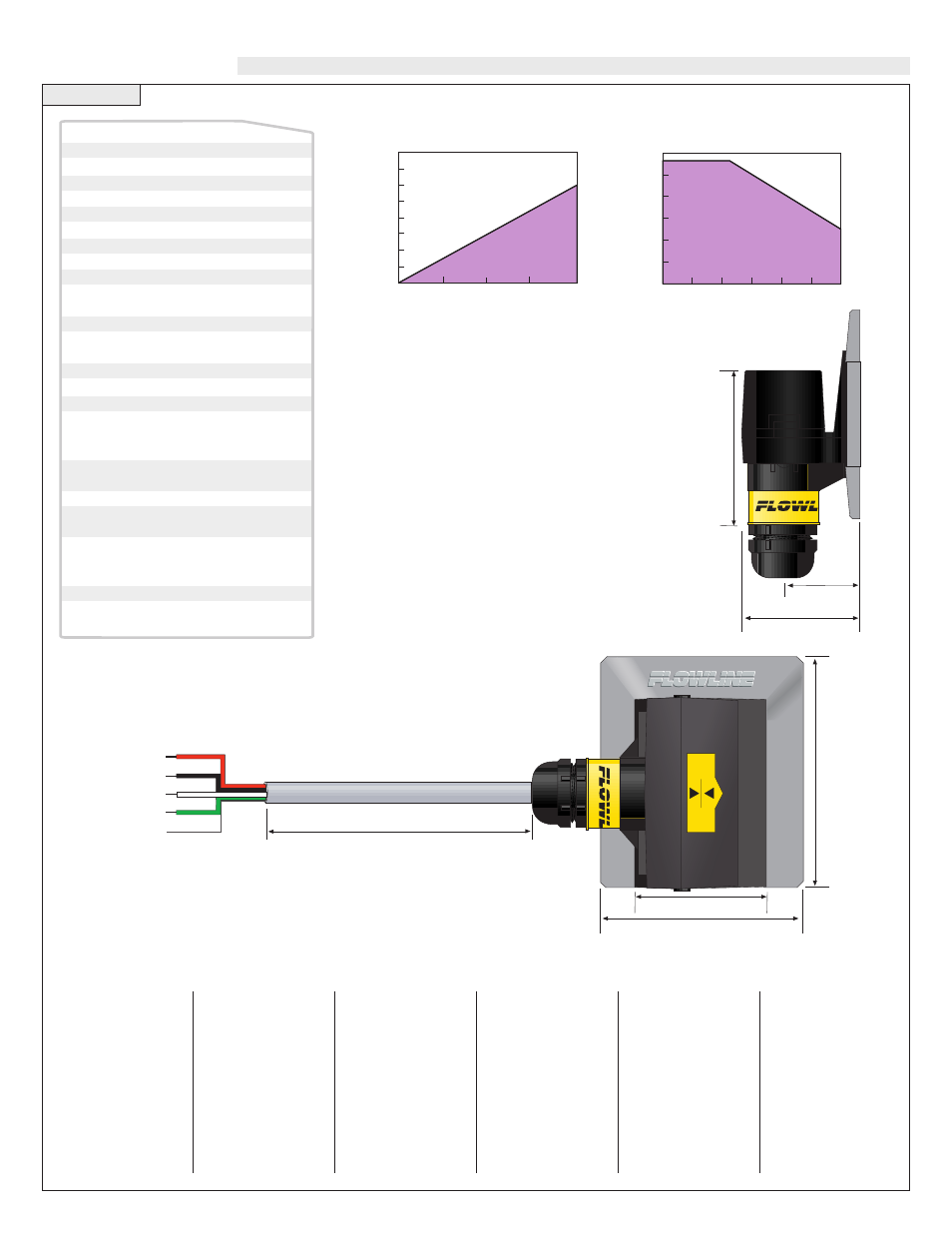

1.7"

(44mm)

2.8"

(71mm)

3.2"

(81mm)

8’ Cable

(2.5m)

(+)

(-)

NO/NC

COM

Shld

Red

RELAY

Black

White

Green

1.0"

(25mm)

1.6"

(41mm)

2

.2

"

(5

6

m

m

)

100

80

60

40

20

00

-20

12 16 20 24 28 32 36

Acceptable

Range

Unacceptable

Range

Maximum Tem. / Voltage Derating

Continuous 20 mA Sinking Curve

A

m

b

ie

n

t

S

e

n

s

o

r

T

e

m

p

e

ra

tu

re

(

¡C

)

Operating Voltage (VDC)

1,600

1,400

1,200

1,000

800

600

400

200

0

12 18 24 30 36

Acceptable

Range

Unacceptable

Range

4-20 mA Sensor

Electrical Loading Limits

M

a

x

.

S

e

ri

e

s

R

e

s

is

ta

n

c

e

(

O

h

m

s

)

Supply Voltage (VDC)

Tank mounting:

Non-intrusive

Tank mat. comp.:

Non-metallic

Tank wall thick.:

< 1" (25 mm)

Accuracy:

±

1 mm in water

Repeatability:

±

0.5 mm in water

Dielectric range:

> 10 constants

Conductive range: > 100 micromhos

Supply voltage:

12-36 VDC

Consumption:

25 mA maximum

Contact type:

(1) SPST relay

Contact rating:

120 VAC/VDC @ 1A

(CE: 60 VAC/VDC @ 1A)

Contact output:

Selectable NO/NC

Process temp.:

F: -40˚ to 176˚

C: -40˚ to 80˚

Enclosure rating:

NEMA 4X (IP65)

Enclosure mat.:

PSO

Conduit entrance: Single, 1/2" NPT

Bracket material:

1 0 0 5 : P P

5005: PVDF

6005: PE

Bracket mounting: 3M adhesive / plastic

thermal weld

Cable jacket mat.:

PP

Cable type:

4-conductor, #22 AWG

(shielded)

Cable length:

Standard: 10' (3m)

Special order: 25'

(7.6m) or 50' (15.2m)

Classification:

General purpose

CE compliance:

EN 61326 EMC

EN 61010-1 safety

Acetone

21

Acetoaldehyde

22.2

Acetyl methyl hexyl

ketone

28

Alcohol

16 to 31

Ammonia

15 to 25

Acetic acid

4.1 to 6.2

Butyl chloride

9.6

Barium chloride

9 to 11

Benzene

2.3

Benzine

2.3

Barium nitrate

5.6

Bromine

3.1

Chlorobenzene

4.7 to 6

Chlorotoluene

4.7

Chloroform

4.5 to 5.0

Chlorine, liquid

2.0

Carbon tetrachloride 2.2

Cyan

2.6

Cyclohexanemethanol 3.7

D.I. Water

20

Ethyl toluene

2.2

Ethyl alcohol

23

Ethylene glycol

37

Ethylene oxide

14

Ethylene dichloride

11 to 17

Ethylene chloride

10.5

Ethyl acetate

6.4

Ethyl salicylate

8.6

Ethyl stearate

2.9

Ethyl silicote

4.1

Formic acid

59

Ferric oleate

2.6

Freon

2.2

Glycerine

47

Glycol

30

Glycol nitrite

27

Gasoline

2 to 2.2

Hydrochloric acid

4.6

Isobutyric acid

2.7

Isobutyl methyl ketone

13

Jet fuel

1.7

Lead carbonate

18

Lead nitrate

38

Methyl salicylate

9.0

Methanol

33

Methyl alcohol 33 to 38

Margarine,liquid 2.8 to 3.2

Methyl acetate

7.3

N-butyl formate

2.4

Nitrobenzene

26 to 35

Nitrotoluene

25

Naphthalene

2.3 to 2.5

Oils, vegetable 2.5 to 3.5

Oils, mineral

2.3 to 2.4

Oils, petroleum 1.8 to 2.2

Oleic acid

2.5

Propane, liquid

1.8 to 1.9

Potassium nitrate

5.0 to 5.9

Potassium chloride

5.0

Stearic acid

2.3

Toluene

2.4

Trichloroethylene

3.4

Trichloroacetic acid

4.5

Terephthalic acid

1.5 to 1.7

Thinner

3.7

Urea

3.5

Vinyl chloride

2.8 to 6

Vinyl alcohol

1.8 to 2.0

Water, 20°C

80

Water, 100°C

48

Table of Common Dielectric Constants:

NOTE: Liquids with a conductivity value > 100 µU are fine if coating is not an issue. Liquids with a dielectric constant less than 20 may not be reli-

ably detected by an LP50 series level switch, depending on conditions.