Dynasonics UFX ULTRASONIC FLOW METER User Manual

Page 9

9

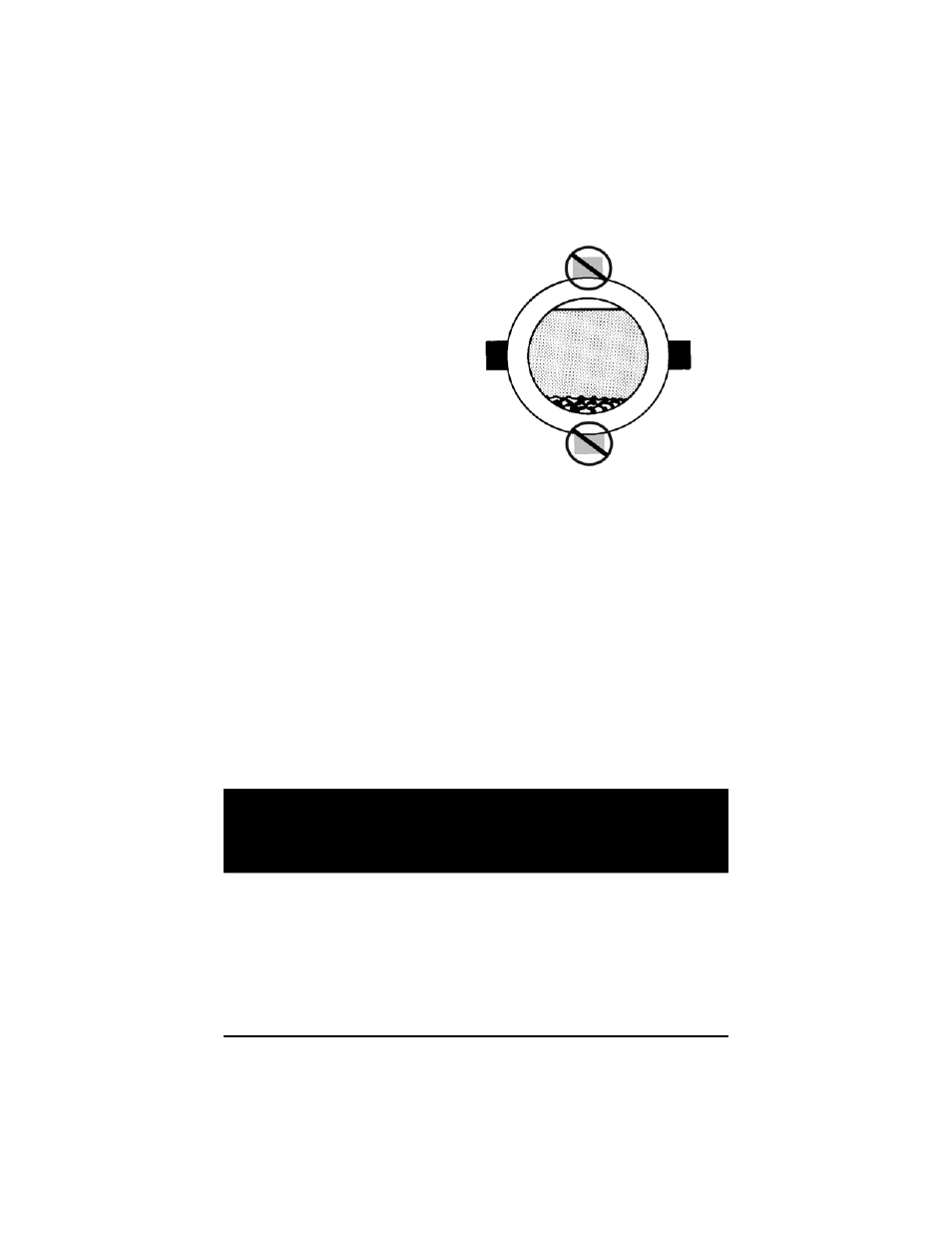

B. MOUNTING LOCATIONS ON THE PIPE

If the transducer is applied to

horizontal pipe, choose a

m o u n t i n g p o s i t i o n a t

approximately 3 o’clock or 9

o’clock, assuming 12 o’clock to

be to top of the pipe. These

positions typically provide

optimum acoustic penetration

into the moving liquid. As

illustrated in Figure 2,

placement at the top or bottom

of the pipe can result in poor

sound penetration due to air

pockets (on the top of the pipe)

or sediment (at the bottom of

the pipe).

If the transducer is applied to vertical pipe, orientation does not matter.

C. PIPE PREPARATION

Before the transducer face can be coupled to a pipe surface, an area

slightly larger than the flat surface of the transducer must be cleaned to

bare metal on the pipe. Remove all scale rust and paint. Thoroughly dry

and clean the mounting surface.

NOTE: For plastic pipes, such as PVC or PVDF, pipe preparation

is typically not required.

D. CONNECTING THE TRANSDUCER

Connect the transducer plug into the transducer jack. The connection is

polarized, so alignment of the keyway is necessary.

NOTE: The splash-resistant environmental seal is provided only when

the transducer plug is secured into the transducer jack. It is advisable

to make this connection before entering an area where the UFX may be

dropped into or splashed with liquid.

E. APPLYING THE TRANSDUCER

To ensure an acoustically conductive path between the transducer face

and the prepared pipe surface, a coupling compound is employed.

Enclosed with the UFX flow meter is a tube of Dow Corning 111 silicone

based grease. This grease is adequate for the majority of installations.

If an alternate grease is utilized, the grease must be specified not to

flow at the temperature of the pipe surface or the ambient conditions.

YES

Figure 2

NO

NO

YES