Before you sharpen your first drill bit, Drill doctor, About the drill doctor – Drill Doctor 750SP User Manual

Page 3: And this manual

2

CONGRATULATIONS

Congratulations

You have just purchased the finest, most accurate and best engineered drill bit sharpener ever created for home

and professional use. It is likely that your experience with this sharpener will be unlike any sharpener you have used

before. We hope that in the next several minutes you will discover how Professional Tool Manufacturing LLC and the Drill

Doctor® help to SIMPLY improve the quality of your life (and your drill bits’ too!).

Before you sharpen your first drill bit

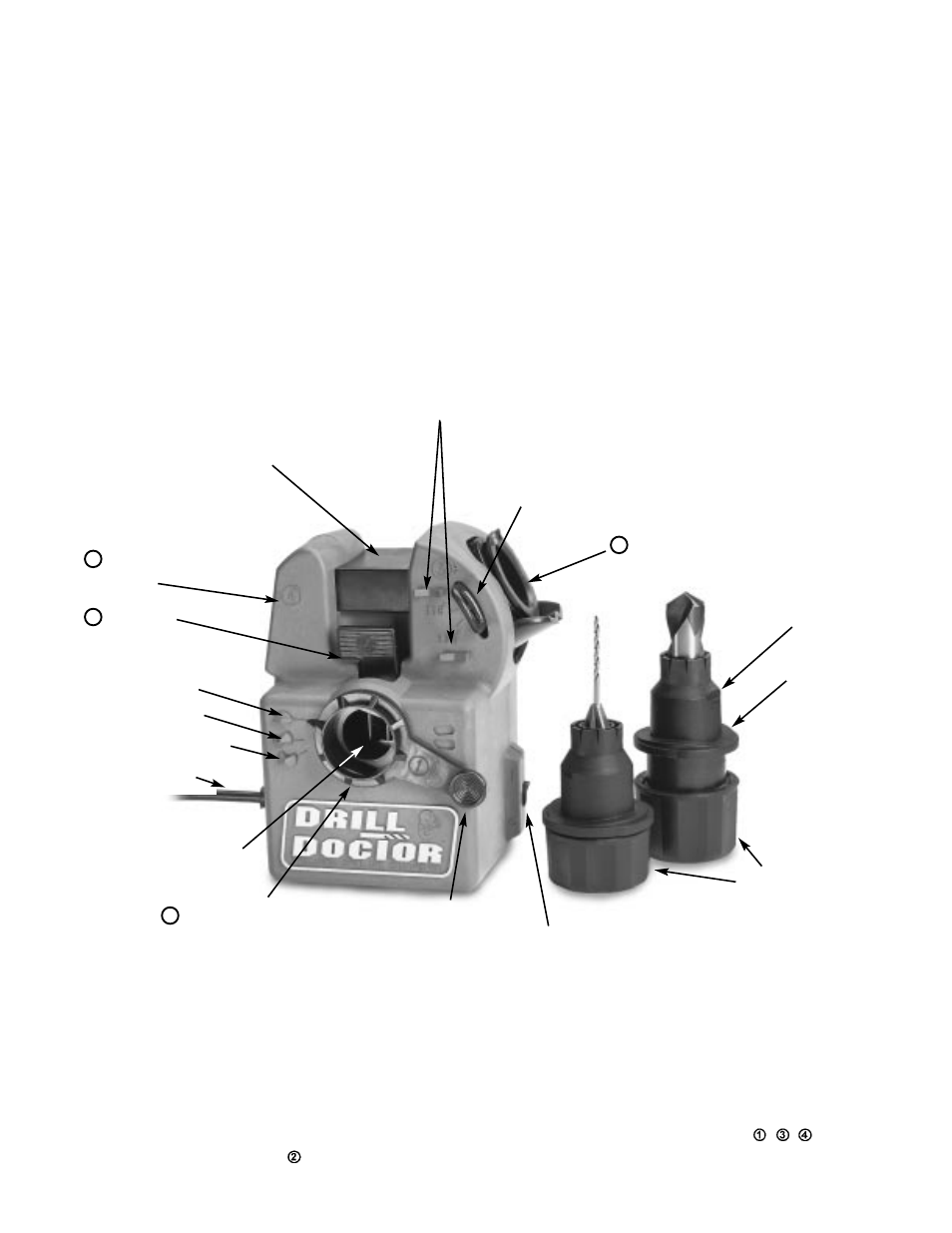

Take a few minutes to familiarize yourself with your new Drill Doctor® and its basic parts. We will refer to all

of the parts and features (Figure 1) during the course of this manual and in the video. There are some features and char-

acteristics unique to the Drill Doctor® which are explained and illustrated within the instruction section of this manual and

the video. Don’t worry, the time it takes to watch the video or read this manual will be made up when you sharpen your

first drill bits. Keep in mind that learning to sharpen drill bits is like learning to ride a bike: it takes a few tries to get it

right, so you should expect that it may take a couple of drill bits to get the “point”.

POINT ANGLE GAUGES

WHEEL COVER

PP01434PF

SPLIT POINT TUBE

STANDARD POINT

POWER CORD

ALIGNMENT TUBE

PP01455PF

ALIGNMENT TUBE

HANDLE

ON/OFF SWITCH

CHUCK KNOBS

3/4” CHUCK

SA01750PA

SHARPENING TUBE

PP01426PA

ANGLE CHANGE LOOP HANDLE

PADDLE

MASONRY

SPLIT POINT

DRILL DOCTOR

®

(

MODEL 750SP Shown)

1/2” CHUCK

SA01500PA

3/4” CHUCK

SA01750PA

1/2” CHUCK

SA01500PA

About the Drill Doctor

®

and this manual

The Drill Doctor® is most efficient when used to resharpen a drill bit’s original point angle. It has been designed

and engineered to sharpen three of the most common drill bit types: standard 118°, high-performance split point 135°, and

carbide 135° masonry (see page 9 for illustrations and applications). With its standard diamond grinding wheel it will sharp-

en high-speed steel, cobalt, parabolic, TiN coated, and solid carbide drill bits. The troubleshooting section of this manual is

designed to anticipate many common questions and applications. To keep your Drill Doctor® and your drill bits in top con-

dition please refer to the maintenance section of this manual. Available replacement wheels and parts are shown in the

exploded diagram (page 8). They are available from Drill Doctor® or your dealer. Please note that the

symbols

refer to the three tubes and the

refers to the paddle on the Drill Doctor®.

FLAT

CAM

4

2

1

3

SPRING STEEL PAWLS

Fig. 1