Operation & maintenance – AAON HB-005 User Manual

Page 26

26

7. Operation & Maintenance

General

Immediately following building occupancy, the air

conditioning system requires a maintenance schedule

to assure continued successful operation. A

maintenance program similar to the example given

below should be scheduled for routine maintenance of

this equipment in order to provide continued efficient

and reliable operation for the owner.

Maintenance Schedule

One week after start-up:

− Check heating and cooling functions.

− Check cycling of compressor and fan. Correct

unusual cycling.

Monthly:

− Inspect evaporator, and condenser coils. Clean if

dirty, or obstructed in any way.

− Inspect air filters. Replace if required.

Annually:

− Clean the condenser, and evaporator coils with

steam, or a non-corrosive coil cleaner.

− Check refrigerant pressures and temperatures

every spring, and correct unusual operation.

Cooling

Coils should be inspected and cleaned at least once

per year to ensure there is no obstruction to airflow.

Evaporator Coil

Dirty evaporator coils will eventually freeze up, and

often result in a time consuming, and expensive

service call. Clean filters will help to prevent dirt from

accumulating on the evaporator; however the

evaporator should be cleaned annually with a soft

bristled brush, and/or a non-corrosive coil cleaning

solution.

Condenser Coil

One of the most overlooked maintenance

requirements is the need to keep air moving freely

across air-cooled condensing coils. Dirty condensers,

like evaporators, can significantly increase cooling

costs during the year. As a minimum, clean the

condenser coil at the beginning of each cooling

season. It is preferable to use a medium pressure

water spray from the inside of the condenser cabinet

with a non-corrosive coil cleaning solution. TURN

OFF all power to the unit before cleaning.

Comb out any visible exterior fin damage to help

maintain unit efficiency.

Condenser Fan

Always check condenser fan blades to ensure

unobstructed, free rotation after manipulating the unit

cabinet in any way, and before turning power back on

to the condenser. Clean the fan blades if they are

dirty.

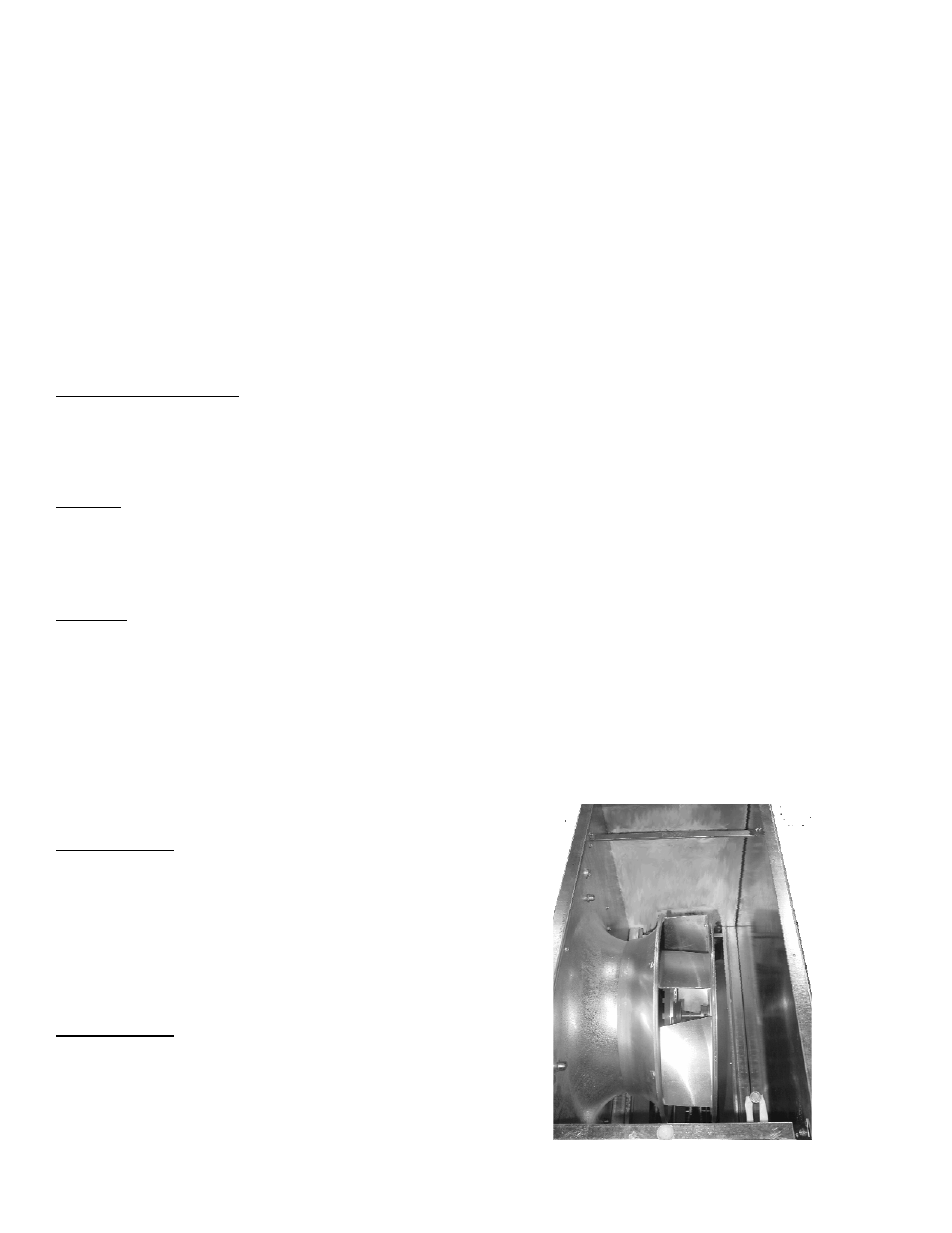

Blower Assembly

HB package units use direct drive, backward inclined

airfoil blower wheels that are non-overloading, very

efficient, and very easy to clean. There are no fan

belts or fan bearings to maintain.

Clean blower wheels are necessary to reduce

electrical use, maintain capacity and reduce stress on

the unit. The blower wheel and blower section need to

be inspected periodically, and cleaned of dust, or

debris.

To inspect and clean the blower; set thermostat to the

“OFF” position; turn the electrical power to the unit to

the “OFF” position at the disconnect switch.

Figure 26a, Blower Section