Zero-Max Aluminum Single Flex Six Bolt Composite Disc Couplings User Manual

Page 3

13200 Sixth Avenue North Plymouth, MN 55441-5509 PHONE (763) 546-4300 FAX (763) 546-8260

Rev 2/12

TOLL FREE 1-800-533-1731

www.zero-max.com

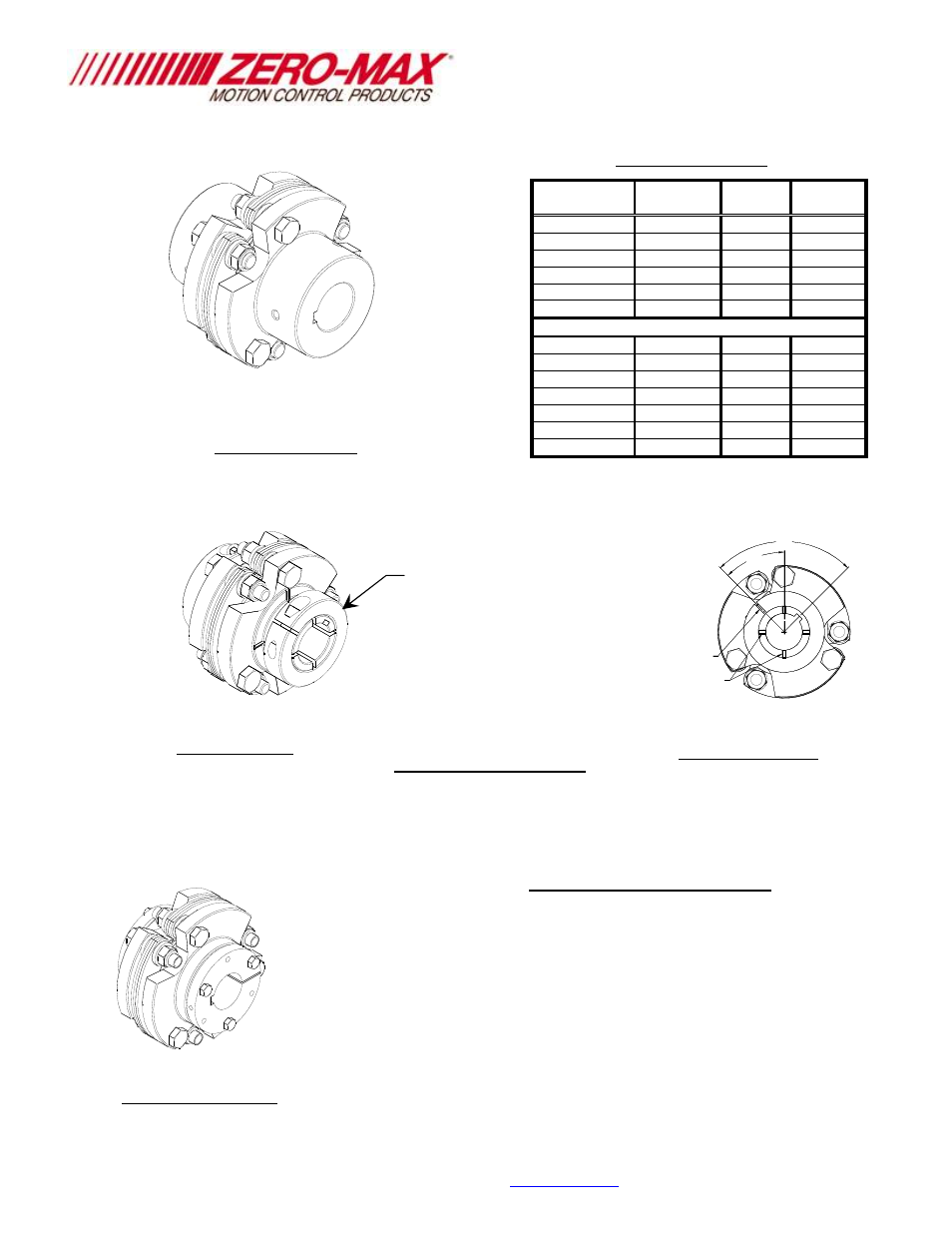

Table 2

Set Screw Torque Table

Screw Size

Wrench

Size

Torque

(in lb)

Torque

(Nm)

#10-32unf 0.094 36 4.1

¼-20unc 0.125

87

9.8

3/8-16unc 0.188

290 33

½-13unc 0.250

620

70

¾-10unc 0.375

2400

271

1”-8unc 0.563

5000

564

Metric

M5 x 0.8

2.5mm

35

4.0

M6 x 1.0

3mm

64

7.2

M8 x 1.25

4mm

150

17

M10 x 1.50

5mm

290

33

M12 x 1.75

6mm

480

54

M20 x 2.50

10mm

2100

237

M24 x 3.00

12mm

3860

440

Clamp Collar

Slot

(4) Hub Slots

90°

45°

Clamp Hub Assembly

Before tightening the clamp collar screw, orient the clamp collar 90 degrees from the keyway centerline

(See Fig 3). If there is no keyway, orient the clamp collar 45 degrees from one of the hub slots (See Fig

3). Tighten clamp screw to tightening torque shown on clamp collar.

Fig. 1

Set Screw Style Hub

Fig. 2

Clamp Style Hub

Fig. 4

QD Bushing Style Hub

Fig. 3

Clamp Slot Location

QD Bushing Hub Assembly

When tightening the QD Bushing bolts the Hub will be pulled toward the

bushing flange. The amount of movement is generally 0.06 to 0.10 inches

(1.5 to 2.5mm) per hub. Install one hub/bushing assembly on the shaft and

tighten the QD bushing to specifications. Place the second hub/bushing

assembly on the shaft with a hub separation of 0.08 less than the “C”

dimension shown in the Table 1 on page 2, See diagram 1. Torque the QD

bushing bolts to the manufacturer’s specification and verify hub separation

and misalignment. Loosen bolt and adjust assembly as needed until hub

separation and misalignment are within specifications. Consult QD bushing

manufacturer’s documentation for proper tightening torque and sequence.

See clamp collar

labels for

tightening torque