Cr a – Zero-Max Stainless Steel Single flex six bolt Composite Disc Couplings User Manual

Page 2

13200 Sixth Avenue North Minneapolis, MN 55441-5509 PHONE (763) 546-4300 FAX (763) 546-8260 DOC NO.: 6AXX-SS-INST Rev B

TOLL FREE 1-800-533-1731

www.zero-max.com

Revised on 5/2/12

8. Tighten the locknuts per the Table 1 tightening torque specifications. Tighten the locknuts of one hub, then those

of the other hub to approximately ½ the stated torque value. Next repeat the process but tightening to the full

torque value. It is also recommended to apply torque on the locknut, not the bolt. Re-check and tighten all

fasteners after several hours of operation to ensure proper tightening.

Note: Aligning the shafts as closely as possible at the time of initial installation will reduce noise and allow the

coupling extra capacity for misalignments and loads which will occur during operation over the life of the connected

equipment. Installing and operating the coupling at higher degrees of misalignment are possible, but will reduce

the life of the composite disc pack. Contact Zero Max with additional questions.

Coupling and shaft alignment should be checked periodically due to foundation settling, equipment shifting, etc.

Alignment should be re-checked after the first several hours of operation.

*Caution: Rotating equipment is potentially dangerous and should be properly guarded. It is the

responsibility of the machine builder, user or operator to follow all applicable safety codes and provide a

suitable guard. Make sure the machine is “locked out” and cannot be accidentally started during

installation or maintenance of coupling.

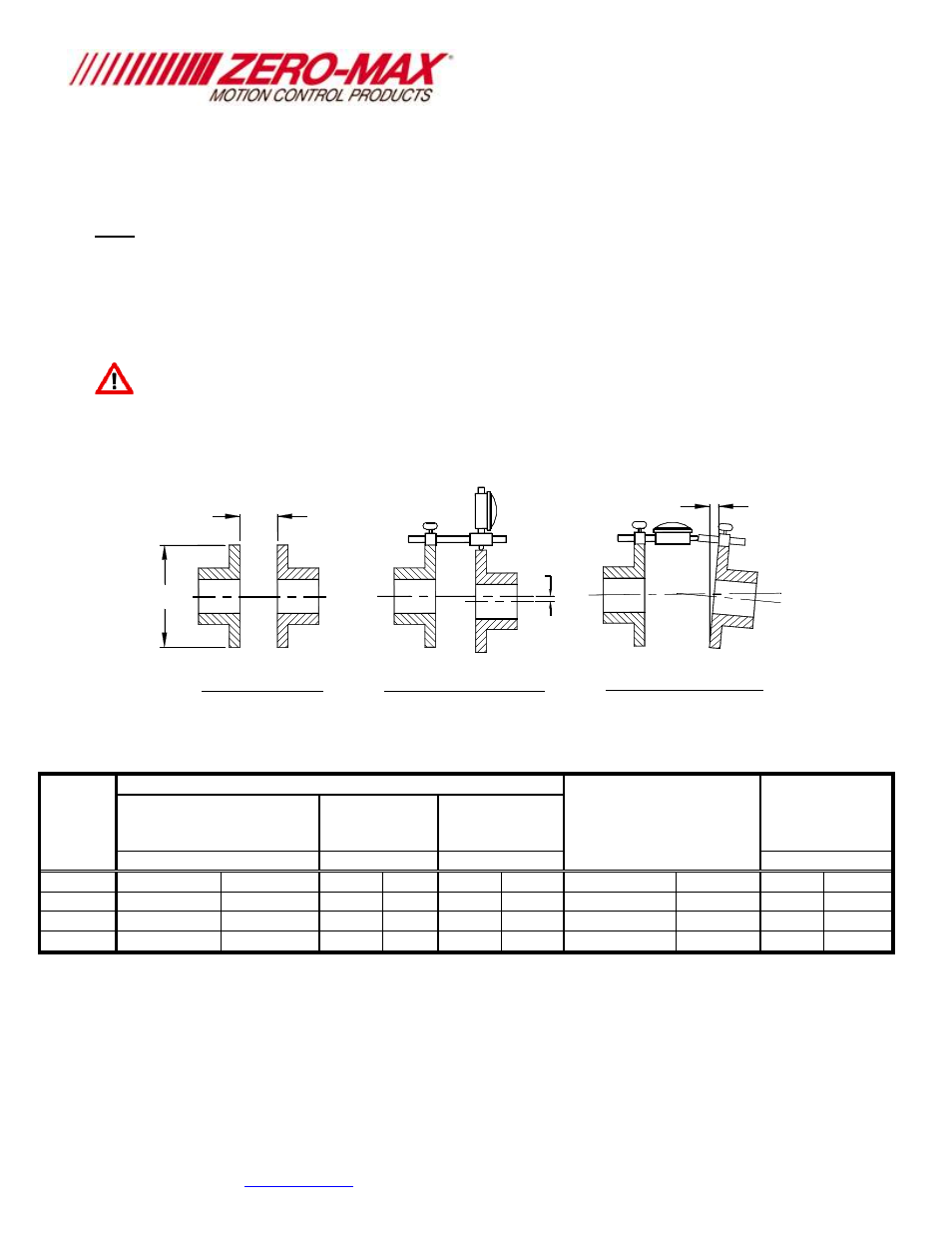

C ± X

A

R

DIAGRAM 2

CHECK PARALLEL MISALIGNMENT

DIAGRAM 1

CHECK ANGULAR MISALIGNMENT

DIAGRAM 3

CHECK HUB SEPARATION

Ø

D

Table 1

Alignment and Assembly Specifications for Stainless Steel Single Flex Series 6Axx-ss

Recommended maximum installed misalignments

Unit

C

R

A

Tightening Torque

Outside

Diameter

See Diagram 1

See Diagram 2

See Diagram 3

(Dry values)

D

Model

Inch

mm

Inch mm Inch mm

Inch mm

6A30-SS

0.460

0.017 11.680.43 0.003 0.08 0.026 0.66

95

in

lb

10.7Nm 3.00 76.2

6A37-SS

0.522

0.023 13.260.58 0.004

0.10

0.033

0.83

230 in lb

26 Nm

3.75

95.3

6A45-SS

0.582

0.030 14.780.76 0.005

0.13

0.039

1.00

38 ft lb

51 Nm

4.50

114.3

6A52-SS

0.646

0.037 16.410.94 0.006

0.15

0.046

1.20

38 ft lb

51 Nm

5.25

133.4

C