Zero-Max ServoClass Coupling User Manual

Page 2

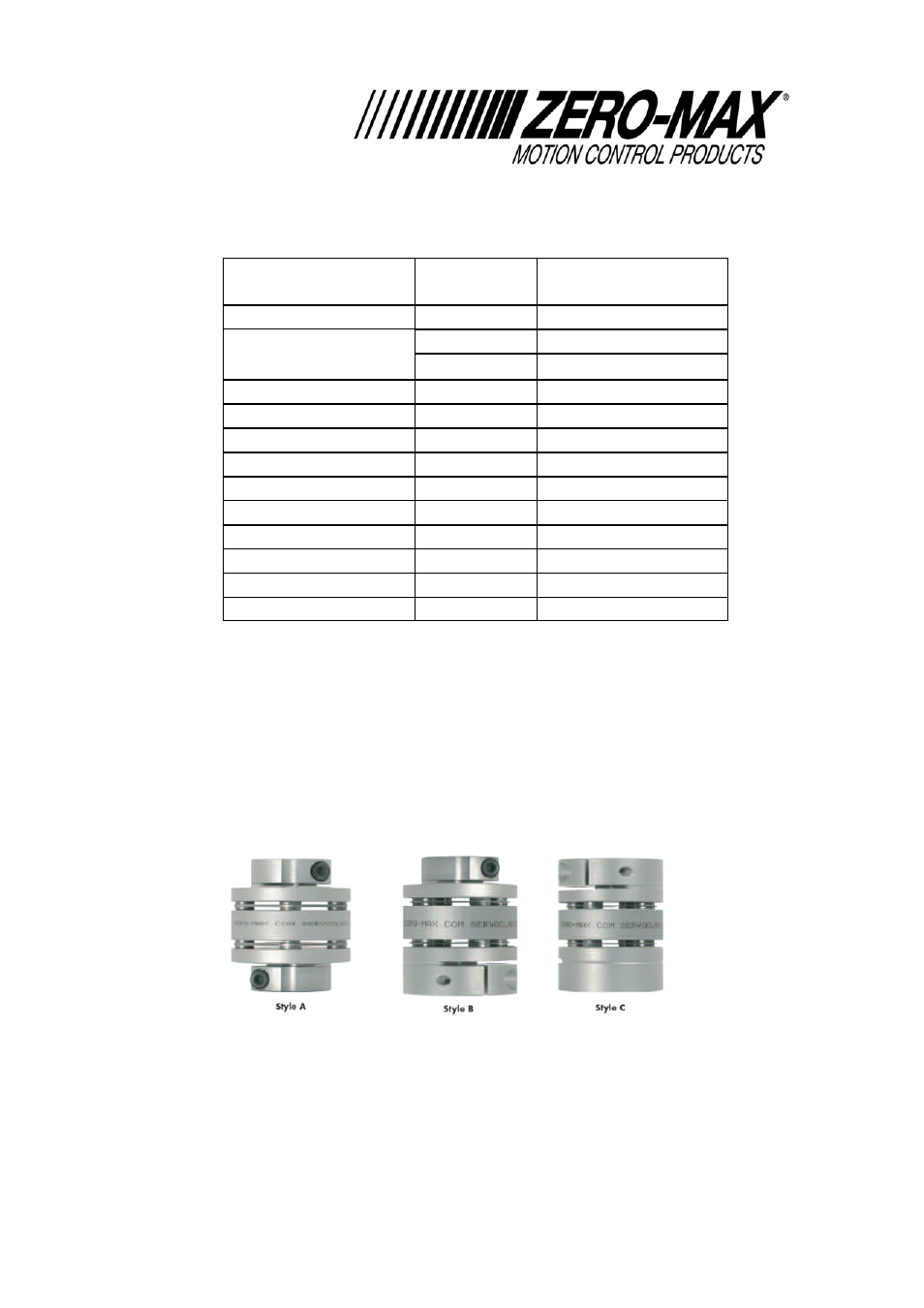

Clamp Screw / Tightening Torque Table

8. After positioning the coupling to the optimal shaft-hub engagement,

tighten the clamp screws to the specified torque value above. A

calibrated torque wrench is recommended for this operation.

The ServoClass

®

Coupling is now ready for operation.

Please contact the factory with any questions.

*NOTE: Aligning the shafts as closely as possible at the time of initial installation will allow the coupling extra

capacity for misalignments and loads which will occur during operation over the life of the connected equipment.

Installing and operating the coupling at higher degrees of misalignment is possible (see catalog ratings), but will

generally reduce the life of the coupling.

*NOTE: Rotating equipment is potentially dangerous and should be properly guarded. The user should follow all

applicable safety codes and provide a suitable guard.

Page 2 of 2

Model

Clamp

Screw Size

Tightening Torque

In. lb.

(Nm)

SC005R or SD005R

M2.0

3.5

(0.4)

SC010R or SD010R

M2.0 **

3.5

(0.4)

SC010R or SD010R

M2.5 ***

9.0

(1.0)

SC020R or SD020R

M2.5

9.0

(1.0)

SC025R or SD025R

M2.5

9.0

(1.0)

SC030R or SD030R

M3.0

13.0

(1.5)

SC035R or SD035R

M4.0

30.0

(3.4)

SC040R or SD040R

M4.0

30.0

(3.4)

SC050R or SD050R

M5.0

62.0

(7.0)

SC060R or SD060R

M6.0

124.0

(14.0)

SC080R or SD080R

M8.0

266.0

(30.0)

SC090R or SD090R

M8.0

266.0

(30.0)

SC100R or SD100R

M8.0

266.0

(30.0)

** for 8mm bore

*** for 4mm - 7mm bores