Alto-Shaam AS F-60G User Manual

Page 15

NOTE:

Perform an initial Boil-Out to clean and

sanitize the fryer station before

operating.

Carbonized deposits along with an accumulation of oil

will eventually build-up on the interior of the frypot as

well as fryer accessories. It is important to periodically

remove these deposits, not only to maintain fryer

efficiency, but also to provide the highest product quality.

NOTE:

Because each fryer station is controlled

separately, the following procedure must

be followed for every component fryer in

multiple-station units.

NOTE:

Manual Boil-Out can only be performed

when the actual temperature of the

frypot is less than 230°F (110°C).

1.

After emptying the fryer of oil or shortening, remove

filter cartridge from unit if equipped with a filtration

system. (See filtration instructions on page 19.) Close

the DRAIN. The handle should be rotated clockwise

until it stops.

NOTE:

Always wear eye protection or a face

shield and protective rubber gloves

when cleaning the frypot as boil-out

chemical is an alkaline solution and can

cause severe burns.

2.

Fill the fryer to the maximum oil fill line with a

mixture of cold water and fryer boil-out solution.

Carefully follow the manufacturer’s directions for

mixing the boil-out solution.

3.

Turn the Master Power Switch (located within the

front access door) to the “ON” position.

4.

Wait until the LED reads “HEAt”, then press the

BOIL OUT

button

on the control panel.

5.

When 192°F (89°C) is reached, the LED will display

“bOIL”

and that temperature will be maintained.

Using a separate timer, allow the frypot to boil-out for

10 minutes.

6.

Turn the Master Power Switch located behind the

front access door to the “OFF” position.

Gas Fryer Operation & Care Manual • 14

O P E R A T I O N

B O I L - O U T

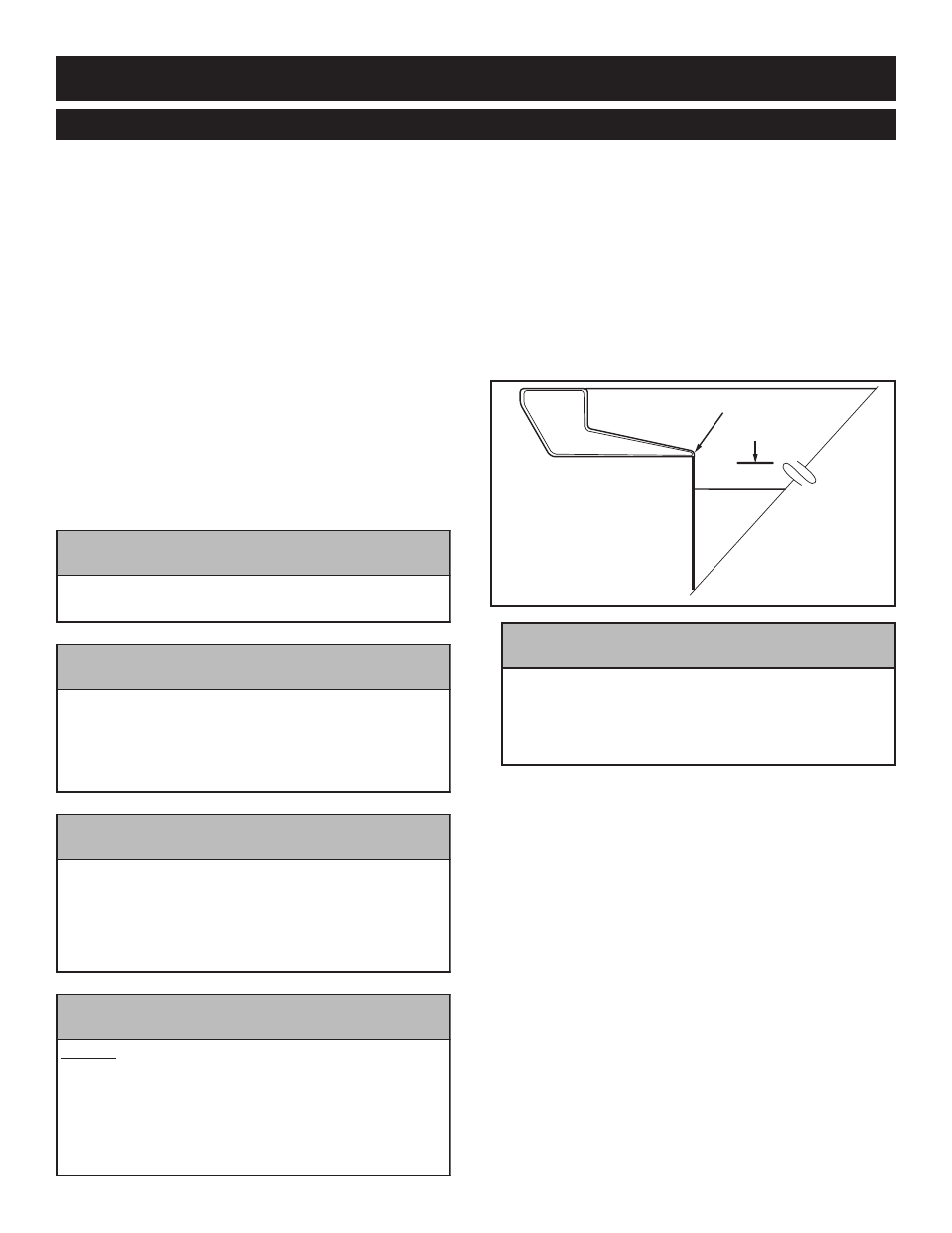

MAXIMUM OIL FILL LINE

MINIMUM

OIL FILL LINE

KETTLE

FRONT

O I L

/

S H O RT E N I N G

L E V E L S

C A U T I O N

TO AVOID DAMAGING THE PUMP AND CONTAMINATING

CLEAN OIL WITH BOIL-OUT CHEMICAL ON UNITS

EQUIPPED WITH A FILTRATION SYSTEM, NEVER ALLOW

BOIL-OUT SOLUTION OR RINSE WATER TO CIRCULATE

THROUGH THE FRYER PUMP SYSTEM OR FAT DRAWER.

C A U T I O N

BEFORE ENTERING THIS PROGRAM, MAKE CERTAIN

THE FRYPOT IS EMPTY OF ALL OIL OR SHORTENING.

C A U T I O N

BOIL-OUT SOLUTION AND SURROUNDING METAL

SURFACES BECOME EXTREMELY HOT. TO AVOID

BURNS, ALWAYS USE HAND PROTECTION WHEN

PERFORMING THE BOIL-OUT FUNCTION AND FOLLOW

THE MANUFACTURER'S SAFETY INSTRUCTIONS FOR

THE BOIL-OUT PRODUCT BEING USED.

C A U T I O N

DO NOT LEAVE THE FRYER UNATTENDED DURING THE

BOIL-OUT PROCESS. THE FRYER MUST BE

CONTINUOUSLY MONITORED FOR BOIL-OVER

CONDITIONS, PARTICULARLY IN HIGH-ALTITUDE

LOCATIONS. IF BOIL-OVER IS IMMINENT, IMMEDIATELY

TURN THE MASTER POWER SWITCH OFF AND ALLOW

THE SOLUTION TO COOL. WHEN THE SOLUTION HAS

COOLED, RE-ENTER THE BOIL-OUT MODE.

C A U T I O N

KEEP A CONTAINER OF COLD WATER ON HAND

DURING BOIL-OUT IN CASE OF BOIL-OVER. IF BOIL-

OVER IS IMMINENT, IMMEDIATELY TURN OFF MASTER

POWER SWITCH AND POUR COLD WATER INTO FRYPOT

TO QUICKLY REDUCE SOLUTION TEMPERATURE.