Schreiber Chillers 2500ACsf User Manual

Page 17

2500AC

15

2. Installation

2.1. General

2.1.1. Locate pump as near liquid source as

possible (below level of liquid for automatic

operation).

2.1.2. Protect from freezing or flooding.

2.1.3. Allow adequate space for servicing and

ventilation.

2.1.4. All piping must be supported

independently of the pump, and must “line-up”

naturally.

CAUTION

Never draw piping into place by forcing the pump suction

and discharge connections.

2.1.5. Avoid unnecessary fittings. Select sizes to

keep friction losses to a minimum.

2.2. Close-Coupled Units:

2.2.1. Units may be installed horizontally,

inclined or vertically.

CAUTION

Do not install with motor below pump. Any leakage or

condensation will affect the motor.

2.2.2. Foundation must be flat and substantial to

eliminate strain when tightening bolts. Use rubber

mounts to minimize noise and vibration.

2.2.3. Tighten motor hold-down bolts before connecting

piping to pump.

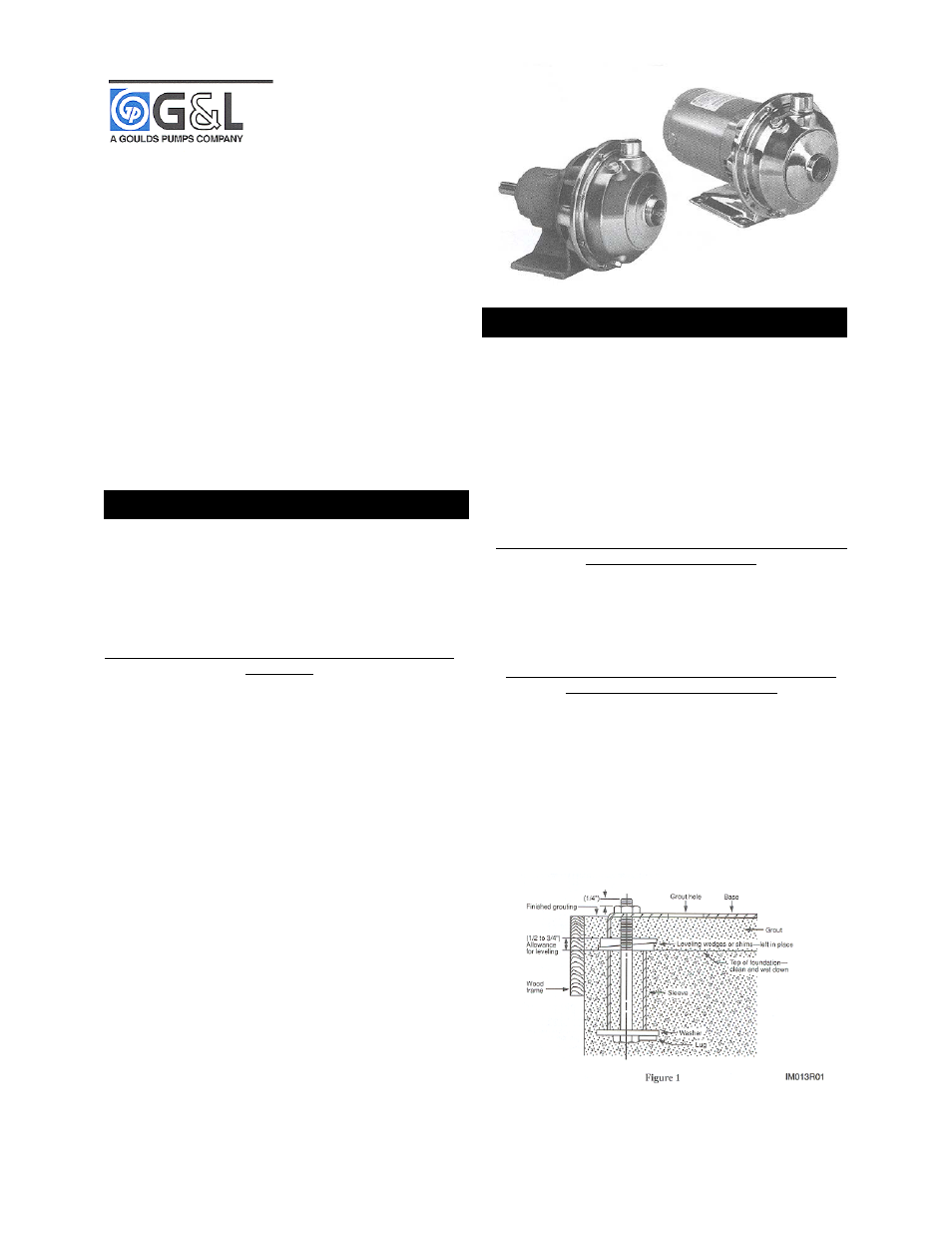

2.3. Frame-Mounted Units:

2.3.1. Bedplate must be grouted to a foundation with

solid footing. Refer to Fig. 1.

1. Important

Installation, Operation and

Maintenance Instructions.

Model NPE/NPE-F

DESCRIPTION & SPECIFICATIONS:

The models NPE (close-coupled) and NPE-F (frame-

mounted) are end suction, single stage centrifugal

pumps for general liquid transfer service, booster

applications, etc. Liquid-end construction is all AISI Type

304 stainless steel, stamped and welded. Impellers are

fully enclosed, non-trimable to immediate diameters.

Casings are fitted with a diffuser for efficiency and for

negligible radial shaft loading.

Close-coupled units have NEMA 48J or 56J

motors with C-face mounting and threaded shaft

extension. Frame-mounted units can be coupled to

motors through a spacer coupling, or belt driven.

1.1. Inspect unit for damage. Report any damage to

carrier/dealer immediately.

1.2. Electrical supply must be a separate branch circuit

with fuses or circuit breakers, wire sizes, etc., per

National and local electrical codes. Install an all-leg

disconnect switch near pump.

CAUTION

Always disconnect electrical power when handling pump

of controls.

1.3. Motors must be wired for proper voltage. Motor

wiring diagram is on motor nameplate. Wire size must

limit maximum voltage drop to 10% of nameplate voltage

at motor terminals, or motor life and pump performance

will be lowered.

1.4. Always use horsepower-rated switches, contactor

and starters.

1.5. Motor Protection

1.5.1. Single-phase: Thermal protection for

single-phase units is sometimes built in (check

nameplate). If no built-in protection is provided,

use a contactor with a proper overload. Fusing

is permissible.

1.5.2. Three-phase: Provide three-leg protection

with properly sized magnetic starter and thermal

overloads.

1.6. Maximum Operating Limits:

Liquid Temperature: 212F (100C) with standard seal.

250F (120C) with optional high

temp seal.

Pressure:

75 PSI.

Starts Per Hour: 20, evenly distributed.

1.7 Regular inspection and maintenance will increase

service life. Base schedule on operating time. Refer to

section 8.