BVA Hydraulics CVS1 User Manual

Page 2

PRODUCT DESCRIPTION

BVA Hydraulics Pressure Switch limits pressure developed

by the hydraulic pump, regulating the force imposed on other

components. A wide variety of applications exist for this

category of product. Special skill, knowledge and training may

be required for a specific task and the product may not be

suitable for all the jobs described above. The user ultimately

must make the decision regarding suitability of the product

for any given task and therefore accept responsibility for that

decision.

WARNING: Always wear proper personal protective

gear when operating hydraulic equipment (i.e. safety

glasses, gloves, etc.)

CAUTION: Always check connections before using.

Alteration of these products is strictly prohibited. Use

only those equipment and attachments provided and

approved by the manufacturer.

WARNING: To reduce the risk of personal injury and/or

property damage, ensure that the rated working pressure

of each pressurized attachment be equal to or greater

than the rated working pressure developed by the hy-

draulic pump.

2

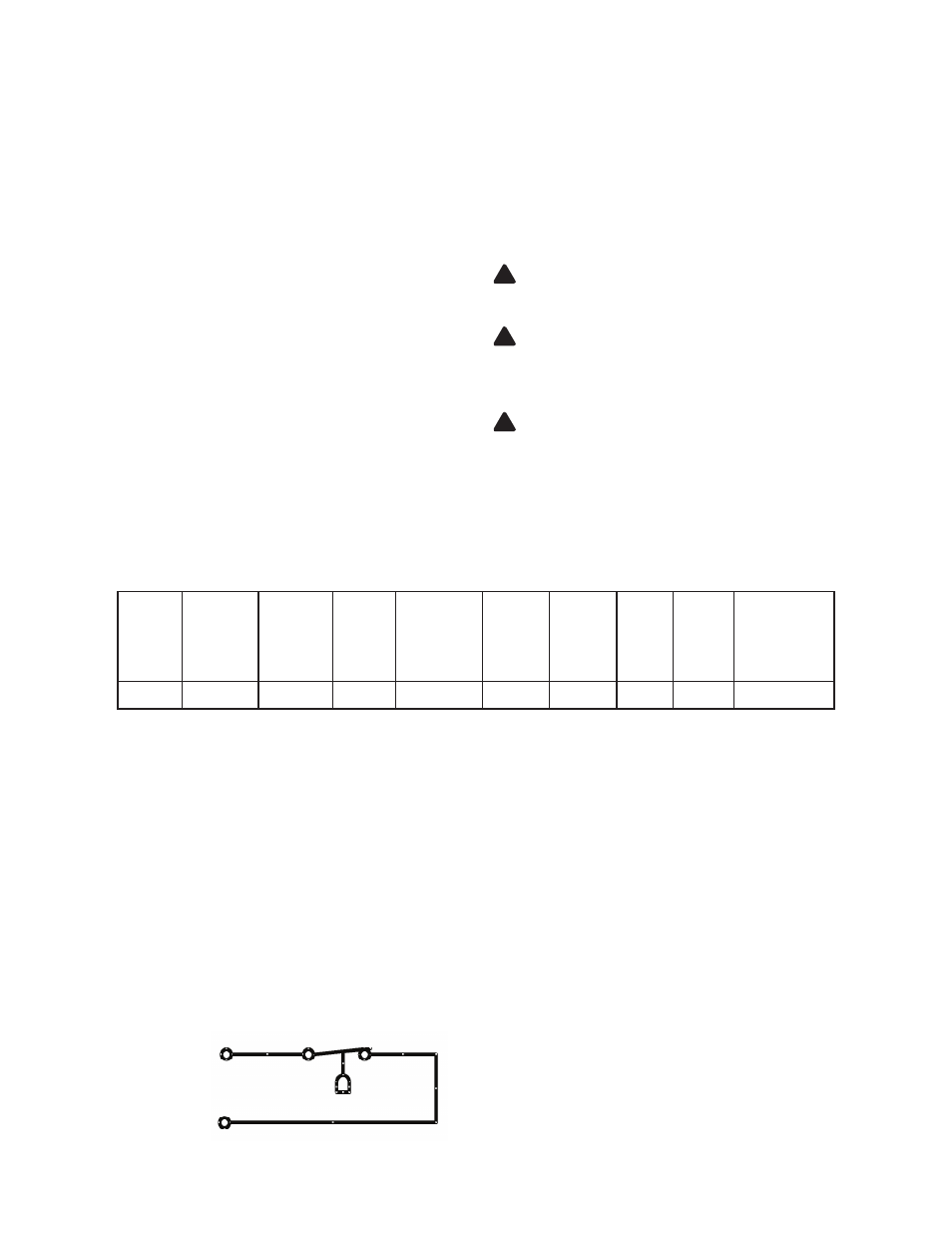

Figure 1 - Switch is wired normally open and held close

by spring force.

SAFETY AND GENERAL INFORMATION

Save these instructions. For your safety, read and understand

the information contained within. The owner and operator shall

have an understanding of this product and safe operating

procedures before attempting to use this product. Instructions

and safety information shall be conveyed in the operator’s

native language before use of this product is authorized. Make

certain that the operator thoroughly understands the inherent

dangers associated with the use and misuse of the product. If

any doubt exists as to the safe and proper use of this product

as outlined in this factory authorized manual, remove from

service immediately.

Inspect before each use. Do not use if leaking, broken, bent,

cracked or otherwise damaged parts are noted. If the valve

has been or suspected to have been damaged, discontinue

use until checked out by a BVA Hydraulics authorized service

center. Owners and operators of this equipment shall be aware

that the use and subsequent repair of this equipment may

require special training and knowledge. It is recommended

that an annual inspection be done by qualified personnel and

that any missing or damaged parts, decals, warning/safety

labels or signs be replaced with BVA Hydraulics authorized

replacement parts only. Any relief valve that appears to be

damaged in any way, is worn or operates abnormally shall be

removed from service immediately until such time as repairs

can be made.

!

!

SPECIFICATIONS

Model

Number

Operating

Pressure

(psi)

Amperage Voltage

Coupler

Size

Length

(in)

Width

(in)

Height

(in)

Weight

(lbs)

Pressure

Switch

Adjustability

(psi)

CVS1

10000

15

250

1/4-18 NPTF

5.622

1.992

1.402

1.32

1,000 - 10150

!

INSTALLATION AND ADJUSTMENT

PUMP MOUNTED INSTALLATION

Mount the pressure switch to the control valve or the manifold

by threading the switch fitting into the port provided for a

pressure gauge. An elbow may be used to change the angle,

and a tee fitting can be used if both a pressure switch and

gauge are required.

PRESSURE REGULATING CONTROL ADJUSTMENTS

The pressure regulating valve can be adjusted to bypass oil

at a specific pressure setting so that the pump will continue

to run. The pressure switch can be adjusted to stop the pump

motor at a specific pressure setting and then restart the pump

when the pressure falls below that setting.

ADJUSTING THE PRESSURE REGULATING VALVE

Adjust the pressure regulating valve by increasing to a

preferred pressure setting. Do not adjust by decreasing from

a higher to a lower pressure.

1. Place pipe plugs in valve ports.

2. Loosen the locknut on the pressure regulating valve. Turn

the adjusting screw a few turns counterclockwise to decrease

the pressure setting to a lower than desired pressure.

3. Connect the pump power supply and place the hydraulic

control valve in the ADVANCE position. Set the motor control

toggle switch to RUN.

4. Slowly turn the adjusting screw in the clockwise direction.

this will gradually increase the pressure setting. When the

preferred setting is reached, lock the adjusting screw in position

by tightnening the locknut.