BVA Hydraulics PA600, PA600H, PA1500, PA1500A, PA1500B, PA2000, PA3801 User Manual

Page 4

BEFORE USE AND SET UP

1. Familiarize yourself with the specifications and illustrations

in this owners manual. Know your pump, its limitations

and how it operates before attempting to use. Refer to

specification chart on page 3 for details of oil port thread

size, usable oil capacity, and more. If in doubt, contact BVA

Hydraulics Technical Service (888) 332-6419.

2.

For models PA1500, PA1500A, PA1500B, PA2000 &

PA3801: Replace shipping plug (red color) with air vent

plug (black color) before use.

3.

Air Connection: Remove plastic cap, connect suitable air

supply to air input port. Air input port is designed to fit the

popular 1/4" NPT air nipple (not included). Ensure that

your air source can dedicate 7.8CFM @ 110~175 PSI to

each pump operated.

4.

Hydraulic Connection: Clean all areas around the oil port

of pump and cylinder. Inspect all threads and fitting for

signs of wear or damage and replace as needed. Clean all

hose ends, couplers and union ends. Remove the manifold

plug, then connect oil output port to suitable fittings and

application/cylinder.

NOTICE: Always secure threaded port connections with high

grade, non-hardening pipe thread sealant. Teflon tape can

be used if only one layer of tape is used and it is applied

carefully, two threads back, to prevent the tape from being

introduced into hydraulic system, which could cause jamming

of precision-fit parts.

WARNING: To reduce the risk of personal injury and/

or property damage, Hydraulic connections must be

securely fastened before building pressure in the system.

Release all system pressure before loosening any

hydraulic connection in the system.

OPERATION

WARNING: Always monitor pressure, load or position

using suitable equipment. Pressure may be monitored by

means of an optional manifold and gauge. Load may be

monitored by means of a load cell and digital indicator.

4

Correct application position can only be determined by

the operator of the equipment.

For Model PA600H: (Hand Button Pump)

1. To extend the cylinder:

a. Close release valve by turning it clockwise firmly.

b. Depress the hand button on top of the air input port

until desired pressure, load or position is reached.

2. To hold the cylinder in position, simply release the hand

button to deactivate the pump.

3. To retract cylinder, open release valve by turning it counter-

clockwise slowly.

For Models PA600, PA1500, PA1500B, PA2000 & PA3801:

1. To extend the cylinder, depress on the foot pedal marked

"Pump" (horizontal portion) until desired pressure, load or

position is reached.

2. To hold the cylinder in position, release the foot pedal to

deactivate the pump.

3. To retract the cylinder, depress the release valve by stepping

on the foot pedal marked "Release" (raised, stirrup shaped

portion).

For Model PA1500A:

1. Install in-line pressure gauge between air pump and

cylinder.

2. Loosen External Pressure Relief Adjustment Screw fully.

3. Begin pumping air while monitoring pressure gauge. Tighten

Adjustment Screw (approximately 1/4 turn increments) until

gauge reaches desired working pressure.

NOTICE: Never operate a pump which is disconnected

from application. If operate in this condition, the hose and

connections will become pressurized. This increases burst

hazard. Damage may occur to pump and its components.

!

!

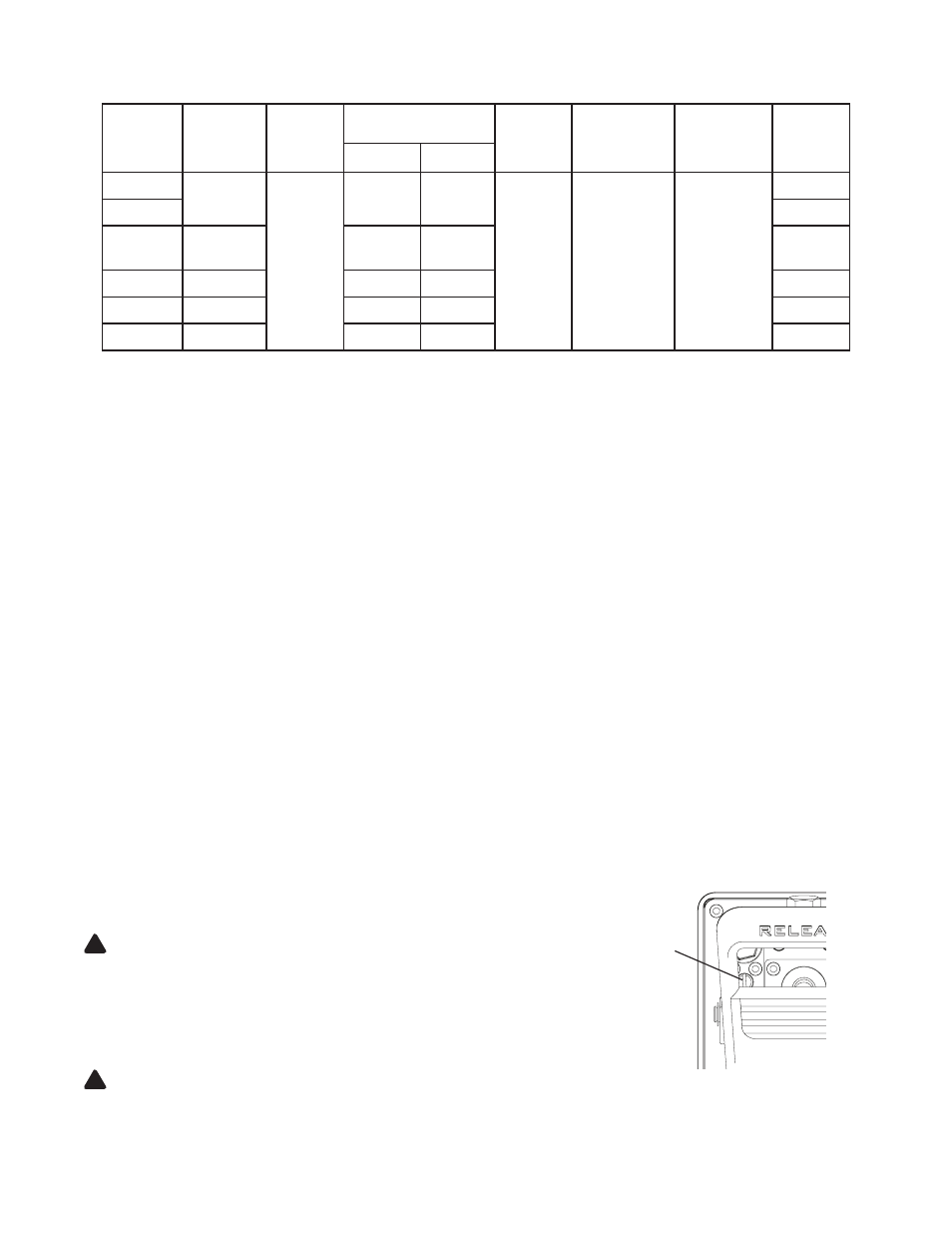

SPECIFICATIONS

Model

Number

Usable Oil

Capacity

(in

3

)

Rated

Pressure

(psi)

Output Flow Rate

(in

3

/min)

Input Air

Pressure

(psi)

Output Port

Thread

(Oil)

Input Port

Threads

(Air)

Weight

(lbs w/

fluid)

No Load

Load

PA600

36.6

10,000

61

9

110 - 175 3/8” -18NPTF 1/4” - 18NPT

14.1

PA600H

12.7

PA1500,

PA1500B

91.5

66

11

18.1

PA1500A

91.5

61

11

18.7

PA2000

122

65

12

20.1

PA3801

231.9

65

12

26.4

External Pressure Relief

Adjustment Screw