BVA Hydraulics PA600, PA600H, PA1500, PA1500A, PA1500B, PA2000, PA3801 User Manual

Page 2

PRODUCT DESCRIPTION

BVA Hydraulics Air Hydraulic Pumps are engineered to meet

most Industrial Standards for Performance and Safety. Its

unique hydraulic circuit

allows quick displacement of hydraulic

fluid under no load conditions and easy pumping in loaded

conditions. These air actuated pumps supply compressed

hydraulic fluid to compatible applications i.e. rams, presses,

spreaders, compactors and crimping machines, anywhere

that 10,000 PSI of fluid pressure is needed.

Special skill,

knowledge and training may be required for a specific task

and the product may not be suitable for all the jobs described

above. Unsuitable applications would include applications that

call for a device to move, level or support persons, animals,

hazardous materials, mobile homes/ dwellings in general,

mirrors and/or plate glass, and/or to connect/secure hatches,

components, etc. between bulkheads. The user must ultimately

make the decision regarding suitability of the product for any

given task and assume the responsibility of safety for himself

or herself and others in the work area.

WARNING: To reduce the risk of personal injury and/

or property damage, ensure that the rated working

pressure of each pressurized attachment be equal to

or greater than the rated working pressure developed

by the hydraulic pump.

WARNING: Always check connections before using.

Alteration of these products is strictly prohibited. Use

only those adapters and attachments provided and

approved by the manufacturer.

2

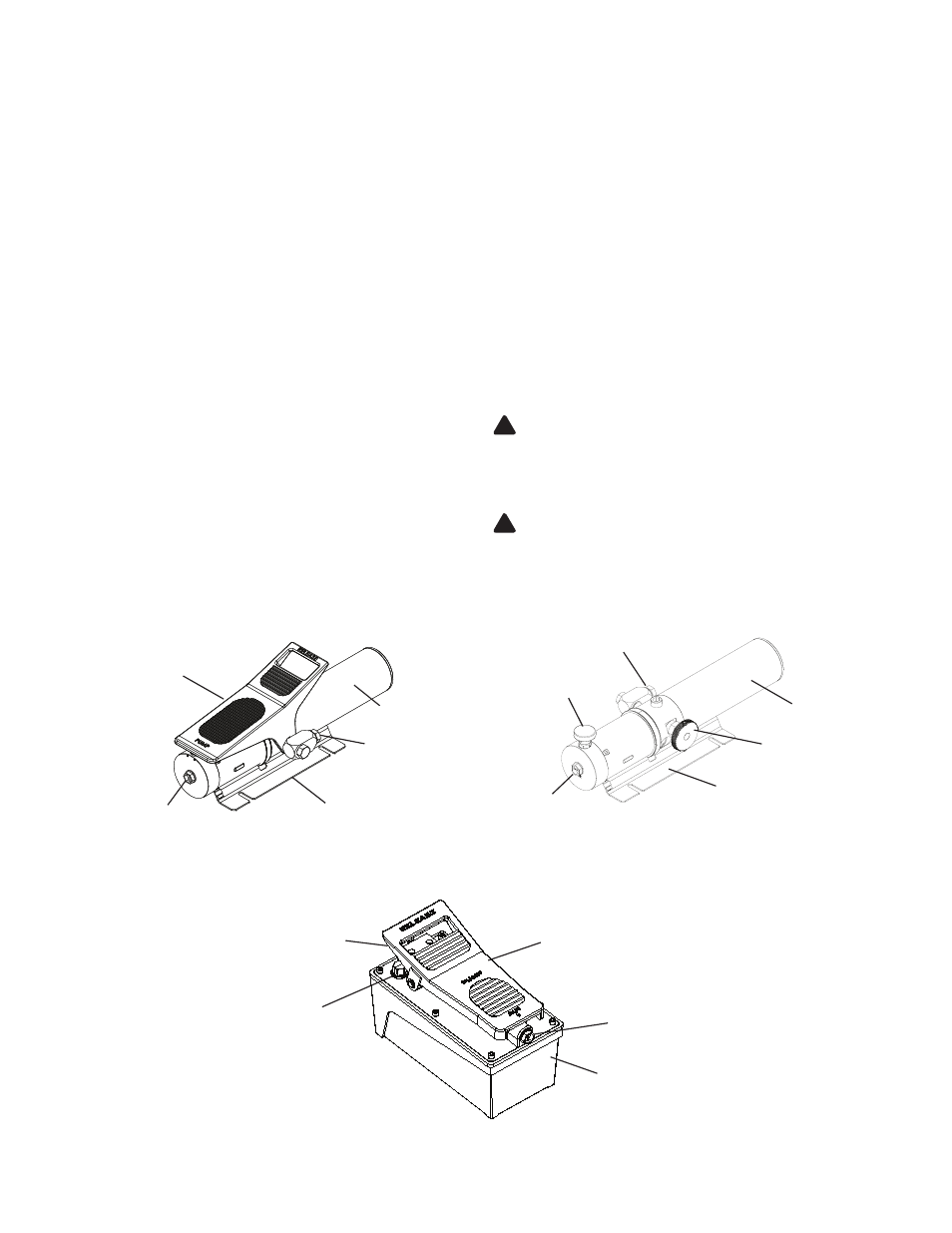

Figure 1 - Model PA600 Components

Figure 2 - Model PA600H Components

SAFETY AND GENERAL INFORMATION

Save these instructions. For your safety, read and understand

the information contained within. The owner and operator shall

have an understanding of this product and safe operating

procedures before attempting to use this product. Instructions

and safety information shall be conveyed in the operator's

native language before use of this product is authorized. Make

certain that the operator thoroughly understands the inherent

dangers associated with the use and misuse of the product. If

any doubt exists as to the safe and proper use of this product

as outlined in this factory authorized manual, remove from

service immediately.

Inspect before each use. It is recommended that, prior to each

use, an inspection be done by qualified personnel and that any

missing or damaged parts, decals, warning/ safety labels or

signs be replaced with BVA Hydraulics authorized replacement

parts only. Any pump that appears to be damaged in any way,

is worn, leaking or operates abnormally shall be removed from

service immediately until such time as repairs can be made.

Any pump that has been or suspected to have been subject

to a shock load (a load dropped suddenly, causing the system

pressure to exceed 10,000 PSI), shall be removed from service

immediately until checked out by a BVA Hydraulics authorized

service center. Owners and operators of this equipment shall

be aware that the use and subsequent repair of this equipment

may require special training and knowledge.

Figure 3 - Models PA1500, PA1500B, PA2000 & PA3801 Components (PA1500 shown)

Reservoir

Foot Pedal

Plastic Cap/

Air Input Port

Reservoir Cap

(not shown)

Manifold Plug/

Oil Output Port

Base Plate

Reservoir

Hand Button

(Advance)

Plastic Cap/

Air Input Port

Manifold Plug/

Oil Output Port

Release

Valve Knob

Base Plate

Reservoir

Manifold Plug/ Oil Output Port

Plastic Cap/ Air Input Port

Foot Pedal

Shipping/ Air Vent Plug

(replace Shipping Plug with

Air Vent Plug prior to use)

!

Reservoir Cap

(not shown)

!