BVA Hydraulics HLN15002--HLN20012 User Manual

Page 3

3

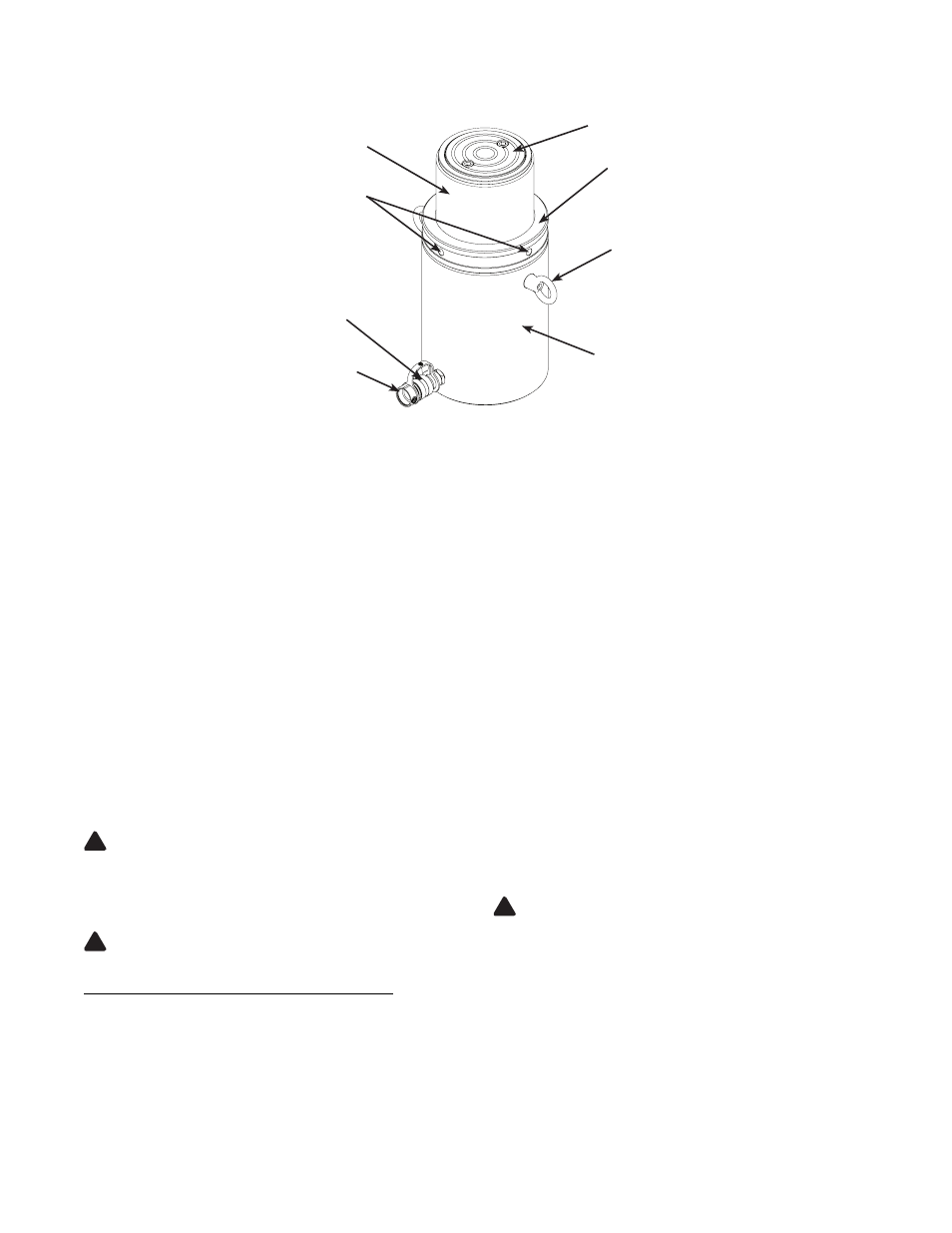

Figure 1 - Typical Lock-Nut Cylinder Components

INSTALLATION

NOTICE: Use an approved, high-grade

pipe sealant to seal

all hydraulic connections.

1. Remove the dust cover and rubber plug from coupler.

2. Inspect all threads and fittings for signs of wear or damage,

and replace as needed. Clean all threads and fittings.

3. Connect hydraulic hose from hydraulic pump to the cylinder

coupler. Ensure that there are no fluid leaks.

4. Install in-line pressure gauge.

5. Check for leaks in system and have repaired by qualified

personnel.

NOTICE: The use of cylinder attachments or extensions

reduces the cylinder capacity by at least 50% per attachment/

extension.

WARNING: Before operating the pump, tighten all

hose connections with proper tools. Do not overtighten.

Connections should only be tightened securely and leak-

free. Overtightening can cause premature thread failure

or high pressure fittings to burst.

WARNING: Before repairs are made, depressurize

cylinder.

Tips for hydraulic hoses & fluid transmission lines:

• Avoid short runs of straight line tubing. Straight line runs

do not provide for expansion and contraction due to

pressure and/or temperature changes.

• Reduce stress in tube lines. Long tubing runs should be

supported by brackets or clips.

BEFORE USE

1. Before using this product, read the owner’s manual

completely and familiarize yourself thoroughly with the

product, its components and recognize the hazards

associated with its use.

2. Verify that the product and the application are compatible.

If in doubt, call BVA Hydraulics Technical Service (888)

332-6419.

3. Inspect before each use. Do not use if bent, broken, leaking

or damaged components are noted.

4. Replace worn or damaged parts and assemblies with BVA

authorized replacement parts only. Lubricate as instructed

in Maintenance Section.

5. Use adequate eye protection when operating or near this

equipment.

6. Ensure method of confirming load is accurate and working

properly. Have gauge or load cell accuracy verified by

qualified personnel on a yearly basis.

7. Cylinders should be stored where protected from the

elements, abrasive dust, and damage. These cylinders

should be stored in the vertical position.

WARNING: As the load is lifted, use blocking and

cribbing to guard against a falling load. Stay clear of a

lifted load before it is properly supported. Never rely on

hydraulic pressure to support a load. Immediately after

lifting, thread the lock-nut into locking position.

!

!

Saddle

Ram Plunger

LIfting Hook

Dust Cover

Coupler

Cylinder

Housing

Height Adjustment

Lock-Nut

Overflow Ports

(helps prevent Ram

Plunger overtravel)

!