External control and programming – B&K Precision 9180 Series - Datasheet User Manual

Page 3

www.bkprecision.com

Programmable Dual-Range DC Power Supplies

9170 & 9180 series

3

External control and programming

Versatile connectivity

These power supplies offer SCPI IEEE488.2 compatible standard USB, optional

GPIB and LAN interfaces, and an optional 8-bit digital I/O and analog control

card to facilitate test system development and integration.

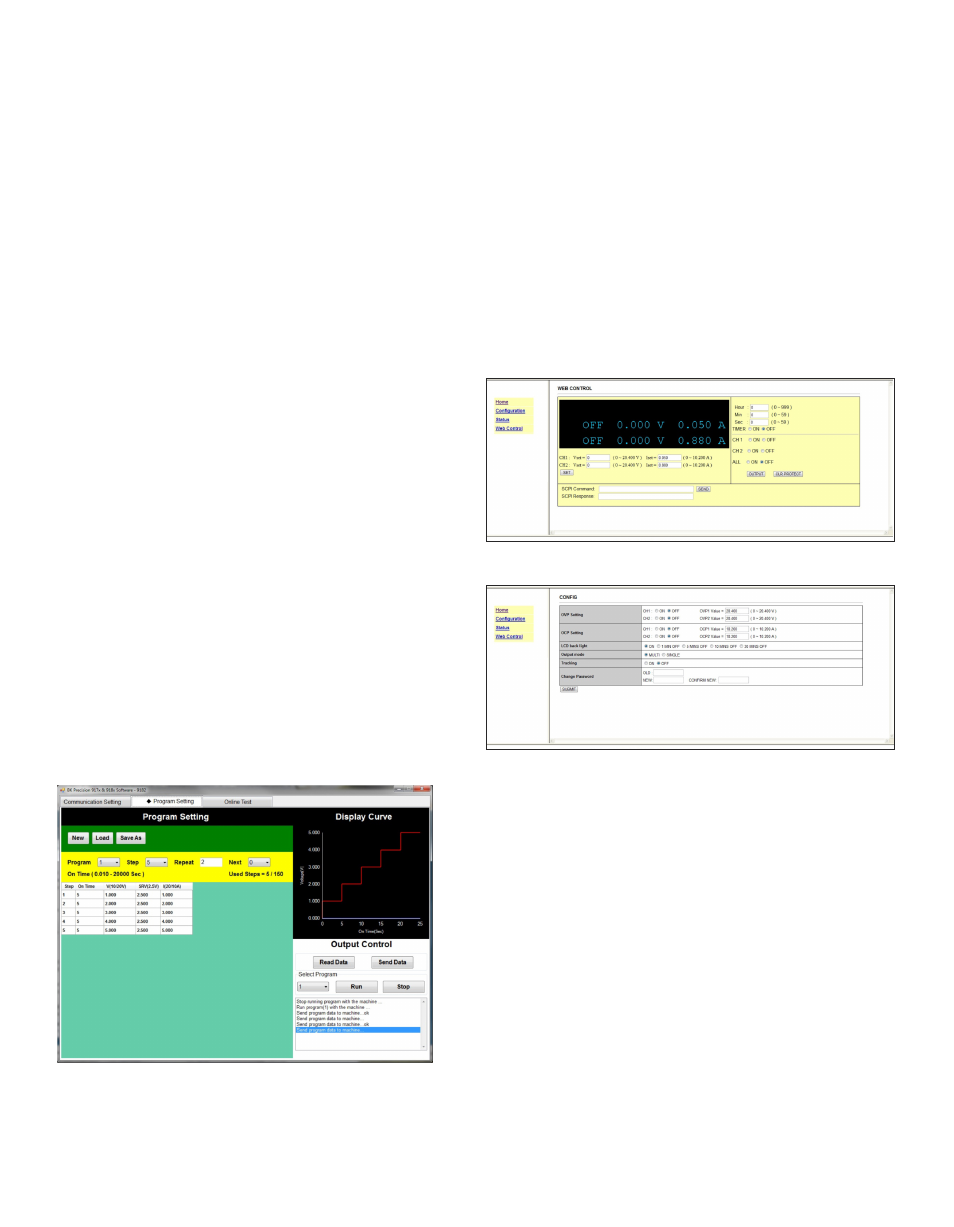

Application software

Create test sequences for execution in list mode via the GPIB or USB interface

using the included PC software.

■

Create, save, and load program lists

■

View output characteristic curves and export data to a file

■

Pass/Fail test monitors maximum and minimum voltage and current values

over a specified period of time

Test sequence execution in list mode

The list mode feature allows users to download a list of commands to the

power supply’s internal memory and execute them. A total of 150 steps can

be allocated to one of 10 internal memory locations. The test sequence can be

programmed remotely through the included application software or via the USB,

GPIB, or LAN interfaces using SCPI commands. Each step’s voltage, current,

and duration parameters can be set, with sequences configured for single or

repeated execution.

Telnet interface

(2)

Power supplies can be controlled with SCPI commands via a Telnet connection

over the Ethernet interface. Any computer with a Telnet client can be used to

control the power supply.

Web server interface

(2)

The 9170/9180 series power supplies with the GPIB/LAN interface installed

provide a built-in Web server that allows users to configure, control, or monitor

the basic settings of the power supply from a remote computer using a Java-

enabled Web browser. Connect to the user-defined IP address to view the web

control page. SCPI commands can also be sent through the Web server interface.

Interface for controlling voltage, current, and output state

Control settings page for configuration of protection

and password settings for the system

External analog programming interface

(1)

The power supplies’ output voltage and current can be controlled by either

external analog voltage or resistance. Use a 0-5 V or 0-10 V external DC

voltage source, or 0-5 kΩ variable resistor to control the output from zero to

full scale.

Multi-unit control

(3)

In multi-unit control mode, up to 31 units can be daisy chained via the RS485

interface for synchronization purposes and controlled from one master unit via

the USB, GPIB, or LAN interface.

(1) Requires card option DR1DIO or DR2DIO

(2) Requires card option DRGL

(3) Requires card option DRRS485