Color, Outside inside, 3/8" filter, regulator and lubricator with guage – Astro Pneumatic 2616 3/8 Filter, Regulator & Lubricator with Gauge User Manual

Page 2

Product: 2616 Manual

Dimension: 17”x 11”/page

Date: 2006/11/10

Color:

3/8" FILTER, REGULATOR AND LUBRICATOR WITH GUAGE

www.astrotools.com

Unpacking

When unpacking, check the parts diagram and part number listing

on page 3 to make sure all parts are included. If any parts are

missing or damage, please call your distributor.

•Astro Pneumatic Tool Co. warrants our products to the original user against

defective material or workmanship for a period of 1 year (except where noted on our

price schedule) from the date of 1st use. Astro reserves the right to determine

whether the product failed because of defective material, workmanship or other

causes and to charge back for missing parts. Astro Pneumatic Tool Co., at its

discretion, will repair products covered under this warranty free of charge. The

distributor should direct the original user to return the product (with the exceptions

listed below) with the distributor’s name, address, adequate proof of date of

purchase or a copy of warranty card, and a short note explaining the problem.

Failures caused by accident, alteration, or misuse are not covered by this

warranty.

•Astro Pneumatic Tool Co. or its authorized service representatives must perform all

warranty repairs. Any repair to the product by unauthorized service representatives

voids this warranty. The rights under this warranty are limited to the original user and

may not be transferred to subsequent owners.

•This warranty is in lieu of all other warranties, expressed or implied, including

warranties of merchantability and fitness for a particular purpose. Some states do

not allow the exclusion of limitations of incidental or consequential damages so the

above limitations may not apply to you. All claims must be sent to:

Astro Pneumatic Tool Company

372 Old US Highway 52 South

Mt. Airy, NC 27030

1 YEAR LIMITED WARRANTY

PLEASE CALL 1-800-221-9705

FOR REPAIR AND RETURN INSTRUCTIONS

2616

3/8" FILTER, REGULATOR AND

LUBRICATOR WITH GUAGE

3/8" FILTER, REGULATOR AND LUBRICATOR WITH GUAGE

• Prevents costly damage to air tools caused by

rust, scale and moisture

• Convenient minimum installation time into your

compressed air system

• Provides clean, dry, regulated compressed air

over a wide range of airflows with accurate control

and fast response

• Efficiently traps moisture while passing through

clean, dry compressed air

• Gauge has rugged polycarbonate case with 2" face

• 1/4" or 3/8" NPT with Max 135psi

• 9-2/5" (L) x 2-2/5" (W)

• Weight: 3lbs.

Page 1

2616

3/8" FILTER, REGULATOR AND

LUBRICATOR WITH GUAGE

Page 2

Call 1.800.221.9705 for questions concerning performance of the product

or other inquiries.

Page 3

2616

372 Old US Highway 52 South

Mount Airy, NC 27030

3/8" FILTER, REGULATOR AND

LUBRICATOR WITH GUAGE

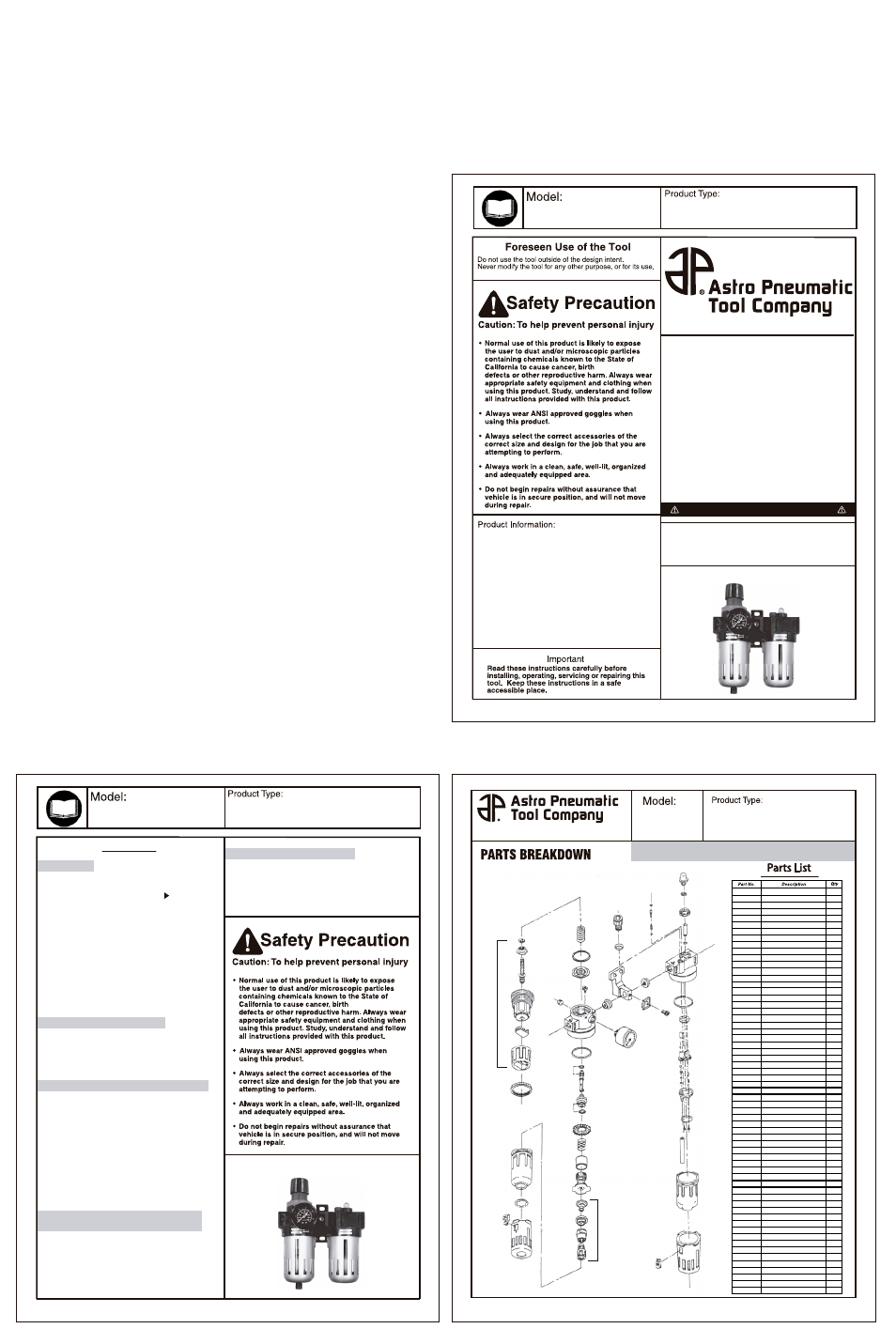

2616-01

2616-02

2616-03

2616-04

2616-05

2616-06

2616-07

2616-08

2616-09

2616-10

2616-11

2616-12

2616-13

2616-14

2616-15

2616-16

2616-17

2616-18

2616-19

2616-20

2616-21

2616-22

2616-23

2616-24

2616-25

2616-26

2616-27

2616-28

2616-29

2616-30

2616-31

2616-32

2616-33

2616-34

2616-35

2616-36

2616-37

2616-38

2616-39

2616-40

2616-41

2616-42

2616-43

2616-44

2616-45

2616-46

2616-47

2616-48

2616-49

2616-50

2616-51

2616-52

2616-53

2616-54

2616-55

2616-56

2616-57

2616-58

2616-59

2616-60

2616-61

Filter Regulator Body

O-Ring

Spiral Baffle

Filter Element

Umbrella Baffle

Drain Cup

Drain Nut

Drain Screw

Plastic Bowl

Bowl Guard

Push Button Key

Rubber

Locking Ring

Exhaust Nozzle

Pressure Packing

Plastic Ring

Spring

Anchor Ring

E-Ring

Regulating Nut

Governor Spindle

Governor Socket

Push Button

Pressure Governor

O-Ring

Spool

Pressure Plug

O-Ring

Spring

Screw

Pressure Guage

Lubricator Body

Distance Piece

Packing

O-Ring

Distance Block

O-Ring

Filter Leaf

Ball Steel

O-Ring

Governor

Spring

Stack Adjustor

Setting Up Piece

Screw

Tube

Plastic Bowl

Adjusting Ring

O-ring

Drip Pipe

O-Ring

Visi-Dome

O-Ring

Filling Plug

Spring

O-Ring

Enjetor Pin

Mounting Bracker

Anchor Block

Screw

Packing

1

2

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

2

19

20

21

22

23

24

18

9

13

11

10

8

7

12

6

5

4

29

28

26

25

27

3

2

1

30

14

15

16

17

54

58

53

61

61

32

49

50

48

56

57

55

56

51

52

59

31

60

2

34

33

35

36

37

38

43

42

39

40

41

44

45

46

47

10

11

1 Set

1 Set

Install the unit as close as possible to the

pneumatic equipment of which they are used for.

Make sure that air flows in from IN. ( the end with

mark which is located on the bottom of the unit)

Install filters and lubricators with the bowls at

the bottom.

When a regulator is mounted using a bracket, remove

the fixing ring, insert the bracket and fix it with the

fixing ring.

Use the bracket to mount the filter or the

lubricator. Insert the bracket and fix the unit in place by

tightening the set bolts.

When two or more units are installed, fix them by

using the bracekts on both ends.

1.

2.

3.

4.

5.

6.

Some parts in this unit are made of polycarbonate.

Never use in the atmosphere of organic solvent. Use

neutral cleanser for cleaning.

Make sure that the sevice pressure does not exceed

9.5kgf/cm2.

1.

2.

3.

Note: If they are fixed at one position only, be careful as

vibration or shock may couse the bracket to be loosened.

Note: Handle the drain knob with fingertips. Turning the

knob too tightly may damage it.

Note: Forcing to tun the handle when it is locked may

cause an air leakage or an impossilbe pressure regulation

MOUNTING

Replenish with air tool oil until bowl is 80% full.

For oil supply volume regulation, turn the handle

counterclockwise for increasing and clockwise for

desceasing. (0 is minimum and 9 is maximum. How-

ever, it is not possible to trun from 9 to 0)

1.

2.

METHOD OF LUBRICATION AND OIL

VOLUME REGULATION (LUBRICATOR)

PRECAUTION ON HANDLING

Drain before it reaches the baffle plate.

Turn the drain knob conterclockwise for draining.

1.

2.

DRAIN / DISCHARGE (FILTER)

When turning the handle clockwise, it increases the

secondary pressure. When turning it

counterclockwise, it decreases the pressure.

Pull the handle out for the pressre regulation. After the

pressure is set, push the handle into the main unit. It

will be locked.

1.

2.

When the supply pressure is high and the setting

pressure is low, it may cause pulsation to the atmo-

spheric pressure to the other end. Throttle the output

end in such a case.

3.

PRESSURE REGULATION (REGULATOR)

Instruction

outside

inside