Anemostat RRSG User Manual

Nstallation, Verview

i

I

NSTALLATION

O

VERVIEW

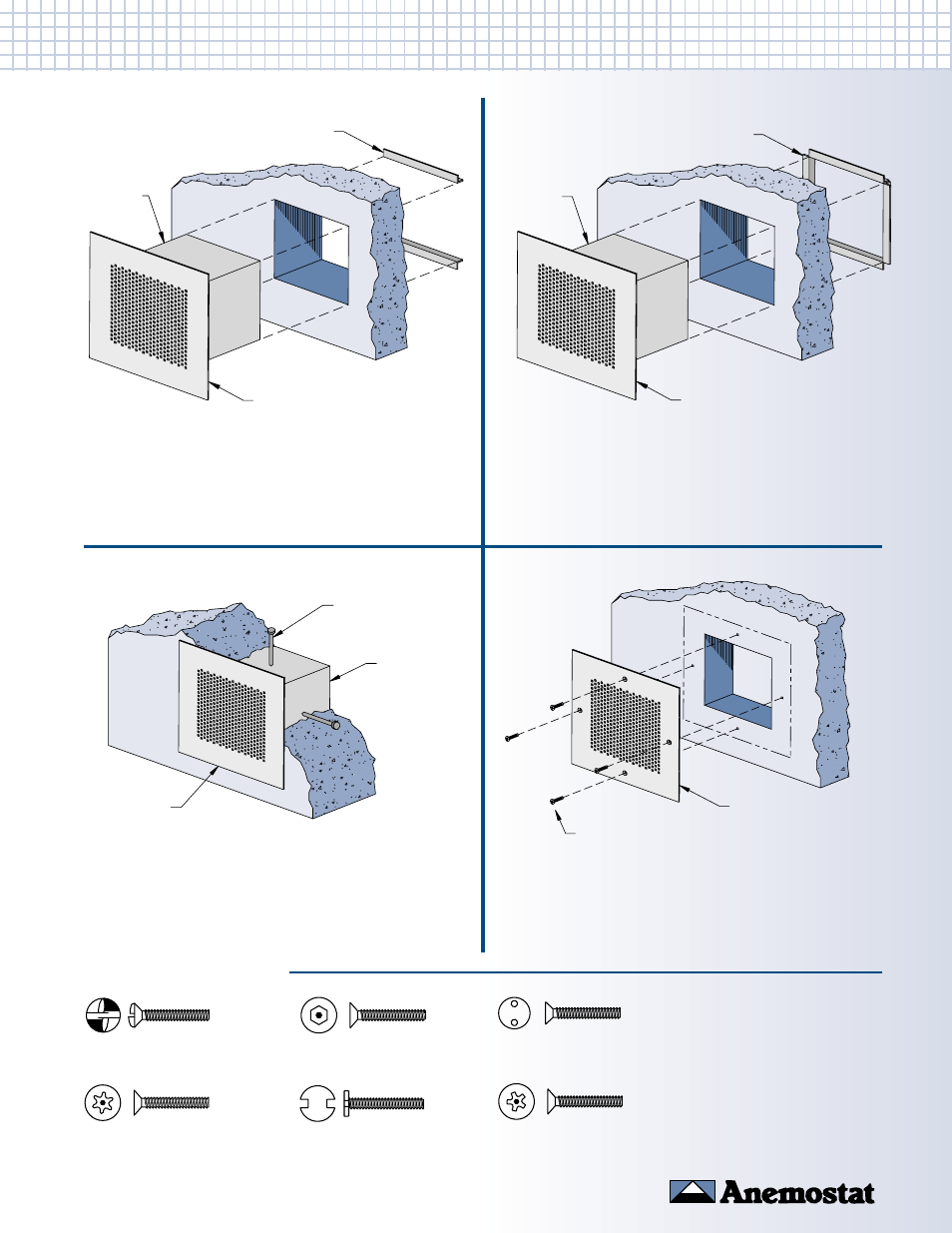

LOCKING ANGLES

1. Set grille into opening and slide through.

2. Weld locking angle to grille sleeve with 1" long stitch

welds at each end and maximum 3" on center.

3. As necessary, seal any gaps around the faceplate

using high quality two component epoxy caulking.

GRILLE FACE PLATE

LOCKING ANGLE (2 PCS.)

GRILLE SLEEVE

ANGLE FRAME (1 PC.)

GRILLE FACE PLATE

GRILLE SLEEVE

LOCKING FRAME

1. Set grille into opening and slide through.

2. Weld locking angle frame to grille sleeve with 1" stitch

welds at both sides of each corner and maximum 6"

on center.

3. As necessary, seal any gaps around the faceplate

using high quality two component epoxy caulking.

ANCHORING STUDS

GRILLE FACE PLATE

GRILLE SLEEVE

STUDS FOR

PRECASTING

SURFACE MOUNTED

GRILLE FACE PLATE

TAMPERPROOF

SCREWS

1. Set grille over opening ensuring that perforated area

is centered.

2. Attach the faceplate using approved tamperproof

screws, and/or anchors as specified.

3. As necessary, seal any gaps around the faceplate

using high quality two component epoxy caulking.

TAMPERPROOF SCREWS

ONE WAY VANDAL PROOF OVAL HEAD

PINNED FLAT HEAD ALLEN SOCKET

NOTCHED SPANNER HEAD

PINNED FLAT HEAD TORX-PLUS

Screwdrivers and insert bits for TamperProof Screws are available. Consult Factory for Price and Availability.

PINNED FLAT HEAD TORX

SNAKE EYE SPANNER

FLAT HEAD (DRILLED SPANNER)

• TAMPERPROOF MACHINE SCREWS SHOWN

• SHEET METAL AND SELF DRILLING SCREWS

(CONSULT FACTORY FOR AVAILABILITY)

1. Position grille into form and pour concrete, or:

2. Position grille onto block and insure studs protrude

through all sides of block opening.

3. Set all blocks and fill with concrete.