American Expedition Vehicles AEV-Nth JK Suspension Systems User Manual

Page 14

IJKS0100R (JK RHD Suspensions).doc

Released: 12-Jan-10

page 14 of 14

COMPLETION

Step 22: Adjustments and ProCal. Assuming the Jeep was properly aligned prior to the suspension

installation, there are only two alignment parameters that have been altered and need to be adjusted:

caster and steering wheel center. If your system included the AEV JK Programmer, you may use it to

accurately center the steering wheel by following the separate instructions provided with it.

Ideal caster for 35-37” tires with either the 3.5” or 4.5” systems is 5 degrees. If step 9 was

performed correctly, you should automatically have about 5°+/-0.5° and not need professional

adjustment using a machine. This setting should deliver good tracking and feel, but different tires and

inflation pressure, road conditions, etc. can affect your results. If you experience tracking issues, you

should double-check your toe settings plus tire inflation and balance and consider having a professional

alignment done if problems persist.

AEV ProCal: Now that your suspension is physically installed along with your larger tires (and

possibly regearing the axles), you should ‘inform’ your JK of these changes by use of the ProCal module

(included with Premium systems and also available separately). On new all-electronic vehicles such as

the JK, it is especially important to adjust tire diameter, axle ratio, and re-center the steering wheel to

restore proper speedometer reading, auto transmission shift points, and ESP functions. Follow the

separate ProCal instructions to perform these adjustments. If you cannot adjust these parameters at the

time of installation, be aware of the discrepancies and performance issues will result and correct them as

soon as possible.

Step 23: Final Torques. Now that the Jeep is fully assembled and sitting on its tires, you may re-torque

all track bar and control arm bolts (upper and lower) to factory torque specs. This must be done with the

vehicle resting on the springs to assure that there is no preload in the bushings which would cause a

harsh ride and premature bushing failures. All other connections should already have been tightened,

but now is a good time to confirm none were missed.

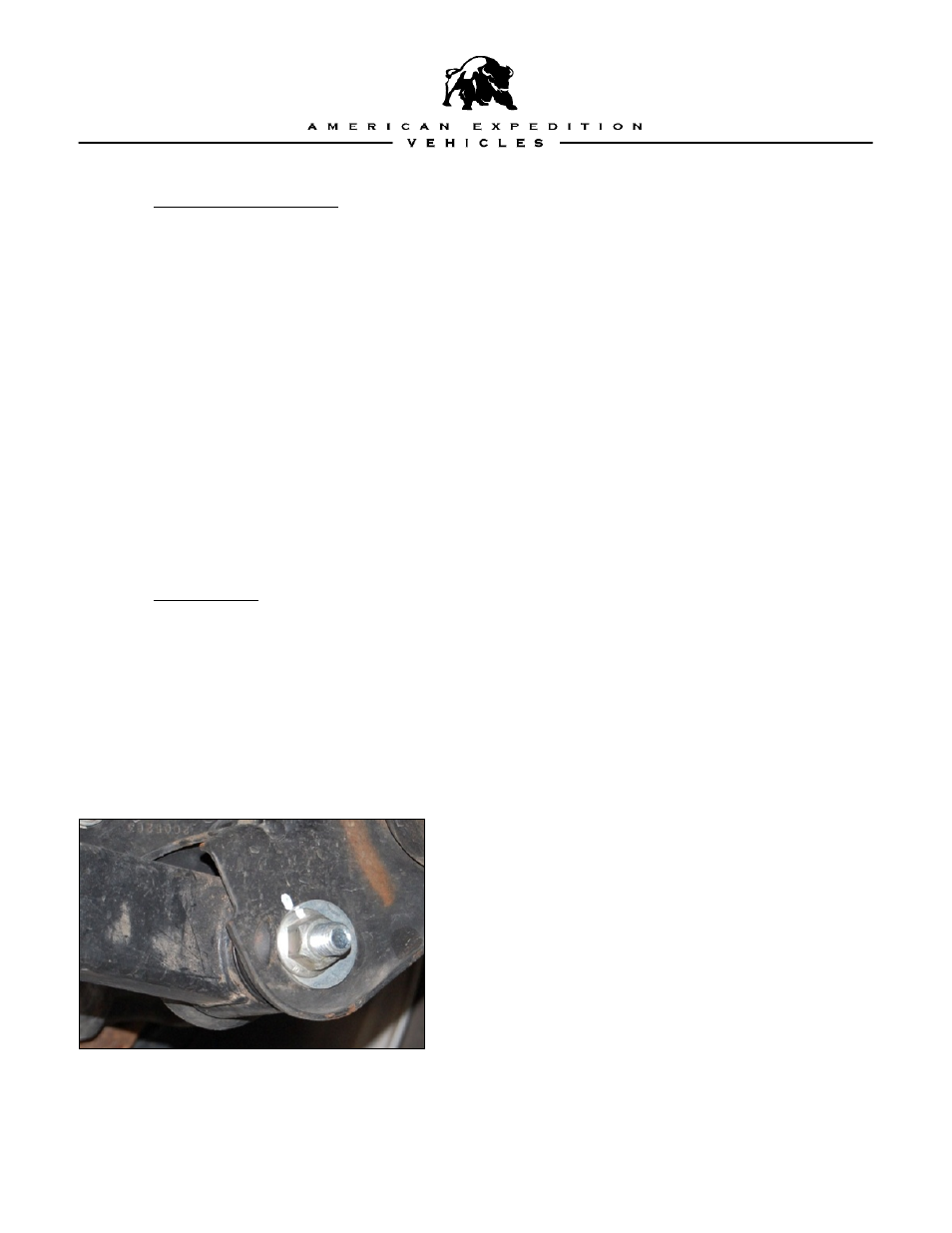

Also, it is good practice to mark each major bolted suspension connection such as these with a paint-pen

– drawing a line that runs from the bolt head or (especially) nut to the adjacent bracket material as shown

in figure 23-1. This will allow a visual inspection to easily catch bolts that work loose (or were never

tight). After ~100 miles of driving, you should perform a complete visual inspection and re-torque any

suspect bolts as well as your wheel lug nuts.

23-1