Elmo Rietschle V-VTN 6/10/15/25/40/60 User Manual

Page 14

14

|

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

Bauj./Nr. 09

S1 3,00 / 3,60

kW

Typ VTR 100 (01)

150 mbar (abs.)

2849751

100 / 120 m³/h

EN 60034

1410 / 1700 min

-1

1027610116

3~

Mot.

Set up and operation

6

1

7

8

9

10

3

4

5

2

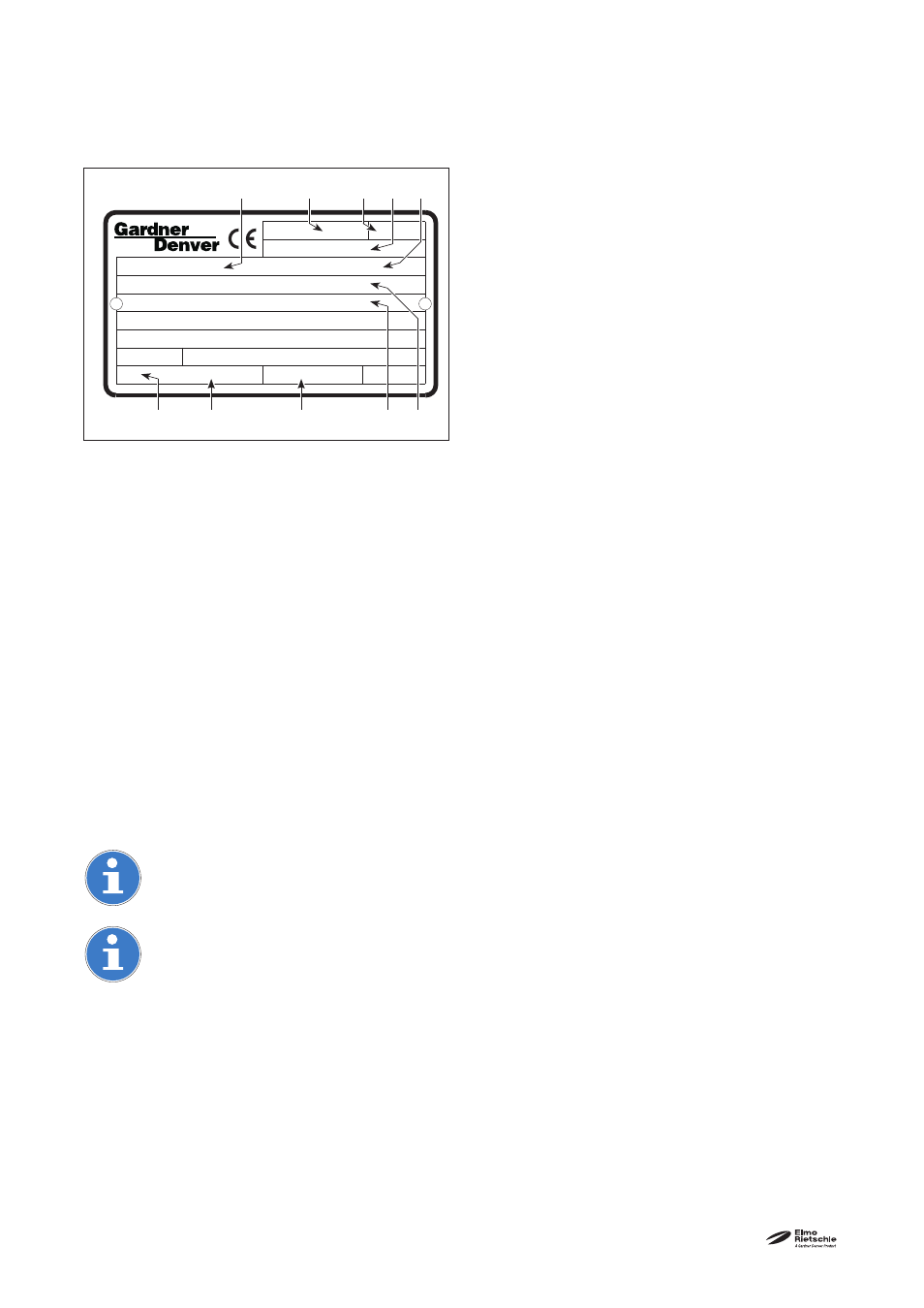

4.1.1 Datenschild

1

Type/ Size (mechanical version)

2

Year of construction

3 Motor

design

4 Serial

number

5 Item

no.

6

Final pressure (abs.)

7

Pumping capacity 50 Hz / 60 Hz

8 Speed

50

Hz / 60

Hz

9

Motor output 50 Hz / 60 Hz

10 Operating

mode

4.2

Description

The V-VTN model range has a connecting thread on the suction side and an exhaust silencer on the pres-

sure side. The aspirated air is cleaned by an inbuilt fi ne micro fi lter.

The motor and the pump have a common shaft.

The V-VTN (01) to (11) are located in a plastic sound cover.

Inside the sound cover is also a fan that pro-

vides cooling.

The V-VTN (13) to (50) are located in a tin cover. It is cooled by the motor fan.

The V-VTN (14) has a ventilation valve on the pressure side (Fig. 3/D

2

).

The V-VTN (02) and (13) have a vacuum regulating valve fi tted as standard (Fig. 2/C) that enables the vacu-

um to be set to the required values which have an upper limit.

4.3

Areas of application

These dry running rotary vane vacuum pumps V-VTN 6 to V-VTN 60 are suitable for evacuating closed sys-

tems and for a permanent vacuum in the intake pressure range 150 - 1000 mbar (abs.).

The pumping capacity with unrestricted suction is 6, 10, 15, 25, 40 and 60 m

3

/h at 50 Hz.

Data sheet D 280

shows the dependency of the pumping capacity on the intake pressure

These dry running machines are suitable for conveying air with a relative humidity of 30 - 90 %.

If the unit is switched on more frequently (at regular intervals of about 10 times an hour) or at

higher ambient temperatures and intake temperatures, the excess temperature limit of the motor

winding and the bearings may be exceeded.

Please contact the manufacturer should the unit be used under such conditions.

If it is installed in the open air the unit must be protected from environmental infl uences, (e.g. by a

protective roof).

Fig. 4 Data plate (example)