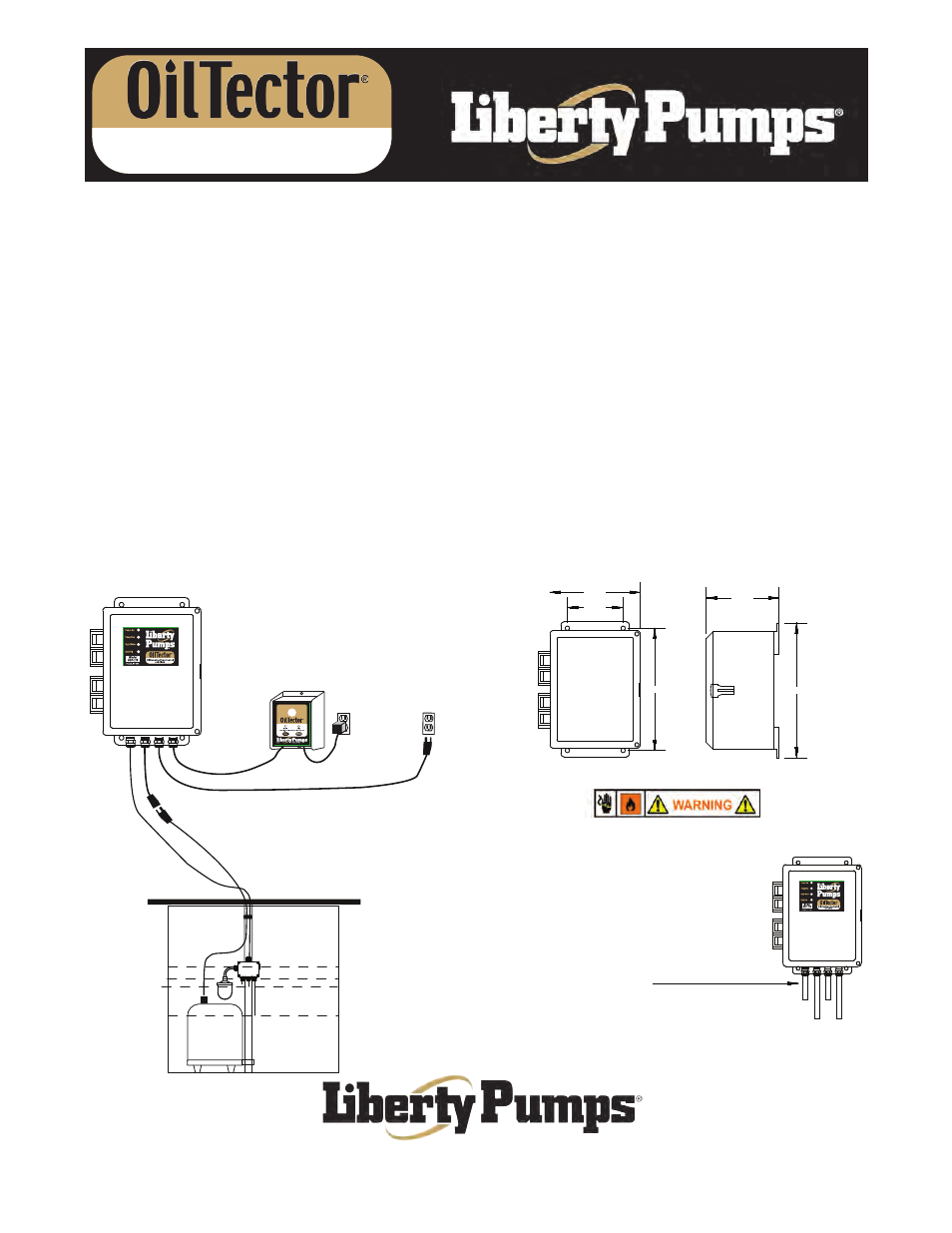

Figure 1, Figure 2, Figure 3 – Liberty Pumps ELV-Series OilTector User Manual

Page 2

Oil “Film”

Detection Level

Pump “On”

Level

Pump “Off”

Level

120 V

Receptacle

Elevator Sump

Control Panel

Remote Alarm has

additional auxiliary

contacts for building

alarm system.

Figure 1

60500A0

Remote alarm can be mounted

2500 ft. from control panel!

Installation of the Control Panel

Description of Operation

9.75"

5.25"

8.82"

.50"

4.02"

Figure 2

7000 Apple Tree Avenue, Bergen, NY 14416 Phone: (800) 543-2550-Fax: (585) 494-1839-www.libertypumps.com

Operation and Maintenance Manual

Page 2 of 6

DWG#7235000H

Manual 7235000H

Operation and Maintenance Manual

On water rise, level reaches pump “start” probe to start the pump. Pump will remain on until level is below

“off” probe. The “off” probe senses air or oil and turns the pump off so the oil layer will not be pumped out of

the sump. If the liquid level reaches alarm probe and mechanical float, the system will differentiate between

water and oil and activate the remote alarm.

1. It is highly recommended to mount the control panel in the same area as the sump pump to eliminate any

splicing of sensor and pump wires. See “Installation of Preset Level Sensor Holder” for more information on

splicing.

2. Determine mounting location for the control panel. Mount panel at the desired location making sure the

mounting location of the control panel is within 6 feet of electrical receptacle.

3. Plug pump cable into control panel receptacle cable. Plug power cable into receptacle only when ready for

testing. See Testing System installation.

4. If the panel is to be installed with conduit, the cables and cord seals must first be removed. Please make

note of wire locations. The incoming power 115V is connected to L1 and L2 of the contactor, pump receptacle

is T1 and T2 on the contactor. Low voltage cable from the level sensing module: green - TB1 off probe,

yellow - TB2 start probe, red - TB3 alarm probe, white - TB4 float, black - TB5 float. Low voltage auxiliary

contacts are TB6 and TB7. Do not mix low voltage probe wires or auxiliary contacts in high voltage conduits.

See figure 3 and figure 6.

Figure 3

Conduit

A Conduit – Low Voltage Preset Level Sensor

B Conduit – High Voltage Pump Cable

C Conduit – High Voltage Incoming Power Cable

D Conduit – Low Voltage Auxiliary Contact for Remote Alarm

Warning – Do not mix high and low voltage circuits in the

same conduit, failure to do so will cause system malfunc-

tion. The Preset Level Sensor and Auxiliary

Contact wires are low voltage class 2 circuits

- Do not install sensor cables in conduits

with main power or pump cables.

60500A0

A B C D

A

B

C

D

120V/240V

Power

Depending

On Model