Gorman-Rupp Pumps SF4A 1488019 and up User Manual

Page 35

SF SERIES

OM-06432

MAINTENANCE AND REPAIR

PAGE E - 10

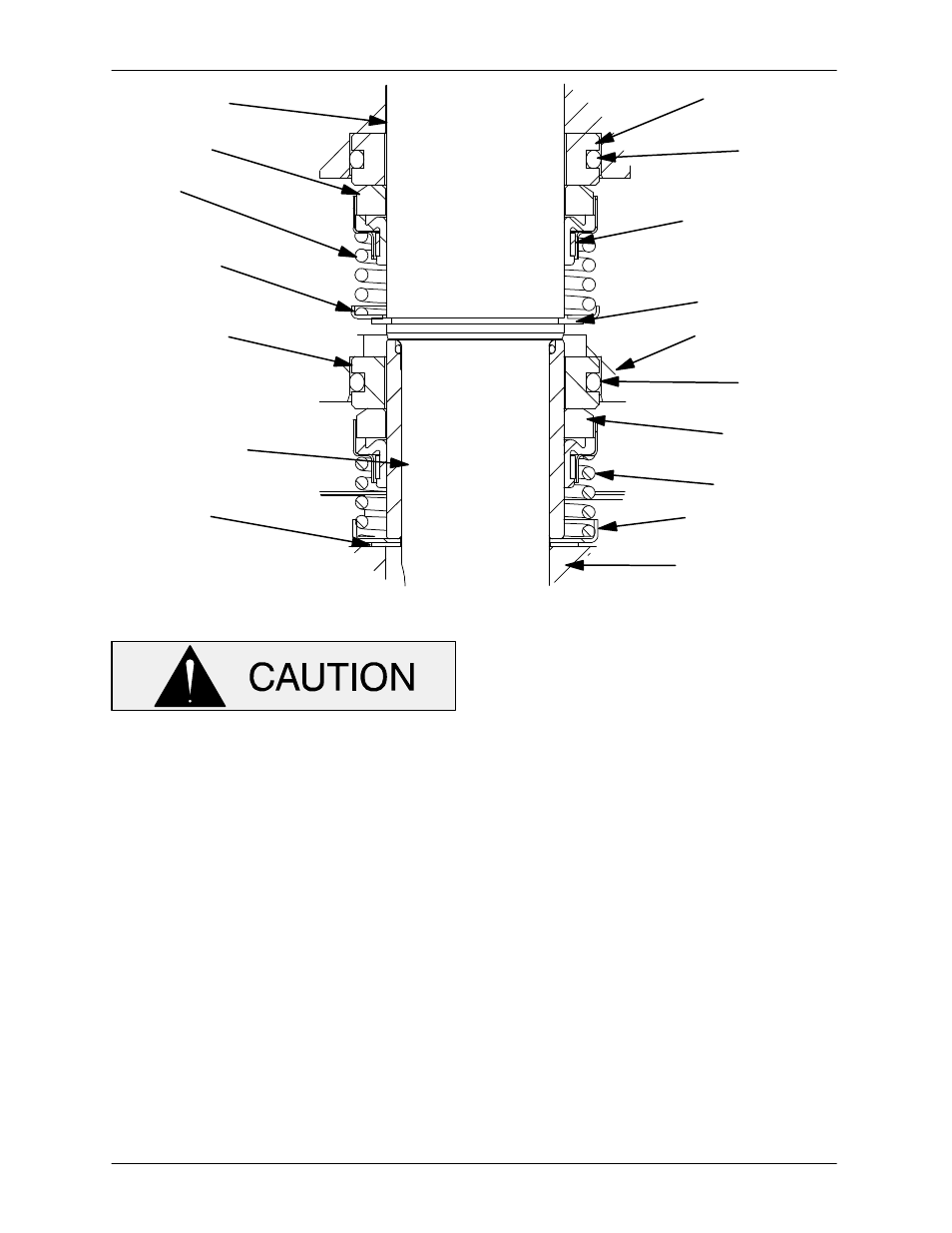

STATIONARY

SEAL SEAT

SPRING

IMPELLER

BELLOWS AND

RETAINER ASSY

ROTOR

SHAFT

ROTATING

ELEMENT

SEAL

RETAINING RING

SEAL PLATE

STATIONARY

SEAL SEAT

SPRING

BELLOWS AND

RETAINER ASSY

SPRING

RETAINER

ROTATING

ELEMENT

SPRING

CENTERING

WASHER

O‐RING

SHIM SET

O‐RING

Figure E-3. Upper And Lower Seal Assemblies

The seal assemblies are not designed for

operation at temperatures above 104

_F

(40

_C). Do not use at higher operating

temperatures.

Upper Seal Installation

(Figures E-2 and E-3)

Do not unwrap a new seal assembly until time of

installation. Cleanliness of seal components is criti

cal, especially the seal faces.

Clean the rotor shaft (3) and seal cavity area of the

intermediate (8). Be sure the area is dry and free of

lint and dirt. Check the seal bore for burrs or nicks

that might prevent a good seal. Remove them with

a fine file or emery cloth to restore original con

tours. If the shaft is bent or damaged, the complete

rotor and shaft must be replaced as an assembly.

Apply a light coating of oil to the bore of the inter

mediate.

Position the intermediate with the impeller end

down on some wood blocks tall enough to allow for

installation of the rotor shaft through the intermedi

ate.

Inspect the rotor shaft (3) and bearings (2 and 5) as

indicated in Bearing and Rotor Shaft Installation

in this section and replace any parts as necessary.

Slide the assembled shaft and bearings into the in

termediate until the lower bearing seats squarely in

the intermediate bore. Secure the rotor and shaft to

the intermediate by installing the snap ring (4) in

the groove in the intermediate bore.

Install a new O‐ring (6) on the shoulder of the inter

mediate.

With the motor housing and stator positioned up

side down, carefully lower the assembled inter

mediate, rotor shaft and bearings into the motor

housing until the female terminal (14) can be se

curely attached to the male terminal (15) on the

moisture sensor.