Installation - section b – Gorman-Rupp Pumps S6B1-E95 575/3 1429763 and up User Manual

Page 9

S SERIES PUMPS

OM-06257

PAGE B - 1

INSTALLATION

INSTALLATION - SECTION B

GENERAL INFORMATION

Review all SAFETY information in Section A.

Since pump installations are seldom identical, this

section is intended only to summarize general rec

ommendations and practices required to inspect,

position, and arrange the pump and piping. If there

are any questions concerning your specific instal

lation, contact your Gorman‐Rupp distributor or

the Gorman‐Rupp Company.

Liquid level devices are available from Gorman‐

Rupp as optional equipment. For information on

installing and operating these items, refer to the lit

erature accompanying them.

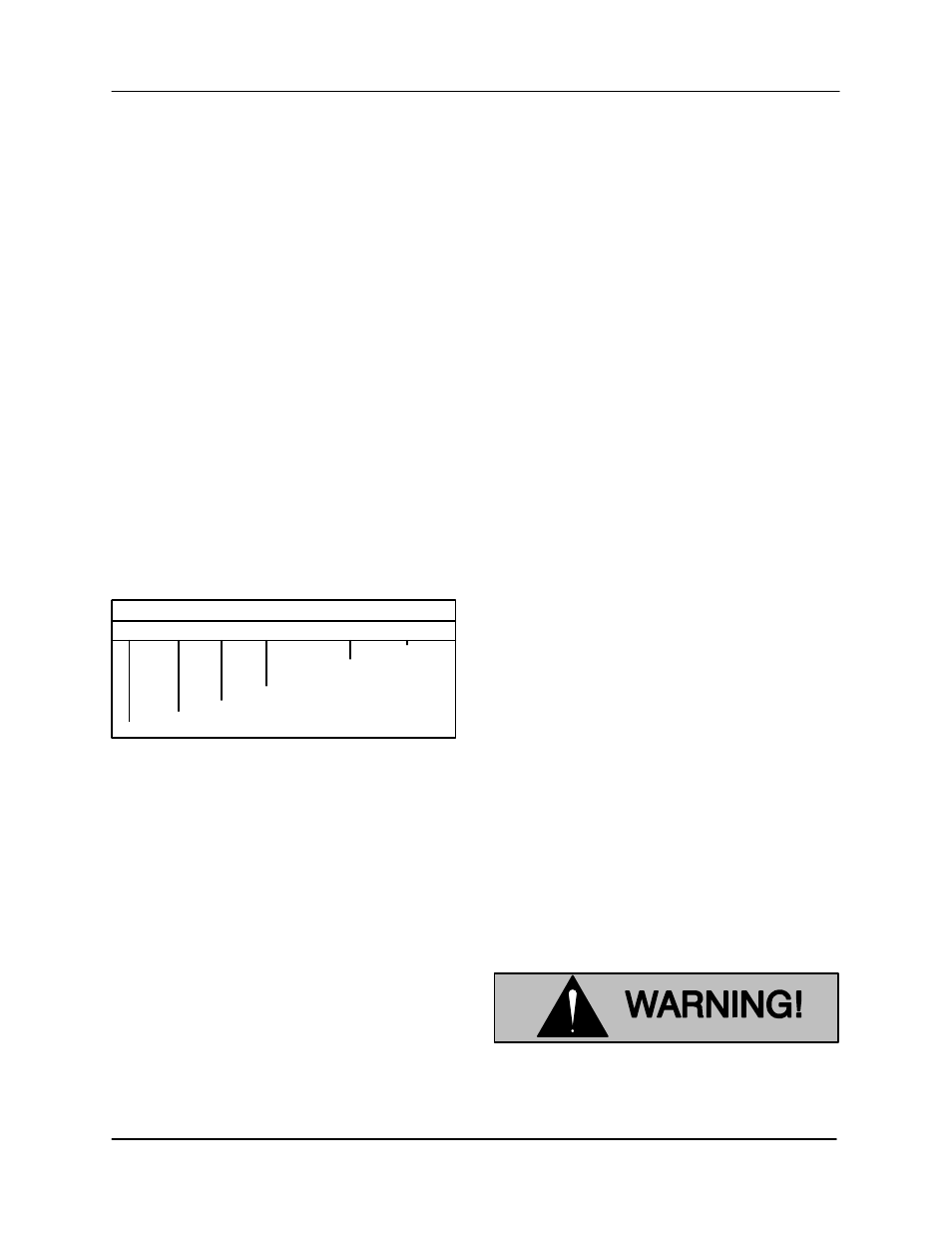

Pump Model Designation

Following is a description of the model numbering

system for S Series pumps. These submersible

pumps are available in a range of sizes. Refer to the

following chart to identify the size of your specific

pump model.

S

Series

Discharge Size

Pump Hydraulics

Pump Construction

H.P.

Voltage/Phase

3

C

1

E

230/3

-

6.2

Pump Model

PREINSTALLATION INSPECTION

The pump assembly was inspected and tested be

fore shipment from the factory. Before installation,

check for damage which may have occurred dur

ing shipment. Check as follows:

a. Inspect the pump assembly for cracks, dents,

damaged threads, and other obvious dam

age.

b. Check for loose attaching hardware. Since

gaskets tend to shrink after drying, check for

loose hardware at the mating surfaces.

c. Inspect the power cable for cuts or any other

obvious damage.

d. Check that amperes, phase, voltage and

hertz indicated on the name plate match the

ratings on the control box and incoming pow

er.

e. Carefully read all tags, decals, and markings

on the pump, and perform all duties indicated.

f. Check for oil leaks. If there is any indication of

an oil leak, see LUBRICATION at the end of

this manual.

PUMP SEAL

There are two shaft seals in the pump. The lower

seal prevents liquid from entering the intermediate

cavity at the impeller end. The upper seal prevents

oil leakage from the motor housing cavity and acts

as back‐up protection in the event of lower seal fail

ure.

LUBRICATION

These pumps utilize two lubrication cavities. The

motor housing cavity provides lubrication to the

motor assembly and bearings, while the intermedi

ate cavity provides lubrication to the pump seal.

The pumps are fully lubricated when shipped from

the factory. However, lubrication levels must be

checked before installing the pump (see LU

BRICATION in MAINTENANCE AND REPAIR -

SECTION E). An additional quart (0,9 liter) of oil is

provided to “top off” the oil level in the pump motor

cavity. If the oil level is abnormally low, determine

the cause before putting the pump into service.

Due to differences in pump design, the quantity of

oil and manner in which oil is to be added to the

seal cavity varies between pump models. Refer to

Table B‐2 for oil capacities and positions for filling

the seal cavity in each pump. Motor cavities requir

ing lubrication should always be positioned verti

cally for filling. Refer to LUBRICATION, Section C

for lubrication specifications and intervals.

PUMP INSTALLATION

When installing or servicing the pump

or controls, follow all requirements for

the installation of wiring or electrical