Gorman-Rupp Pumps S6B1-E95 575/3 1429763 and up User Manual

Page 49

OM-06257

S SERIES PUMPS

PAGE E - 23

MAINTENANCE AND REPAIR

cavity for its full duration first, then use the shutoff

valve to maintain the motor cavity vacuum while

testing the seal cavity. The motor cavity vacuum

must be higher than the vacuum in the seal cavity

to prevent separation of the seal faces or unseating

the stationary seal seat between the seal and mo

tor cavities.

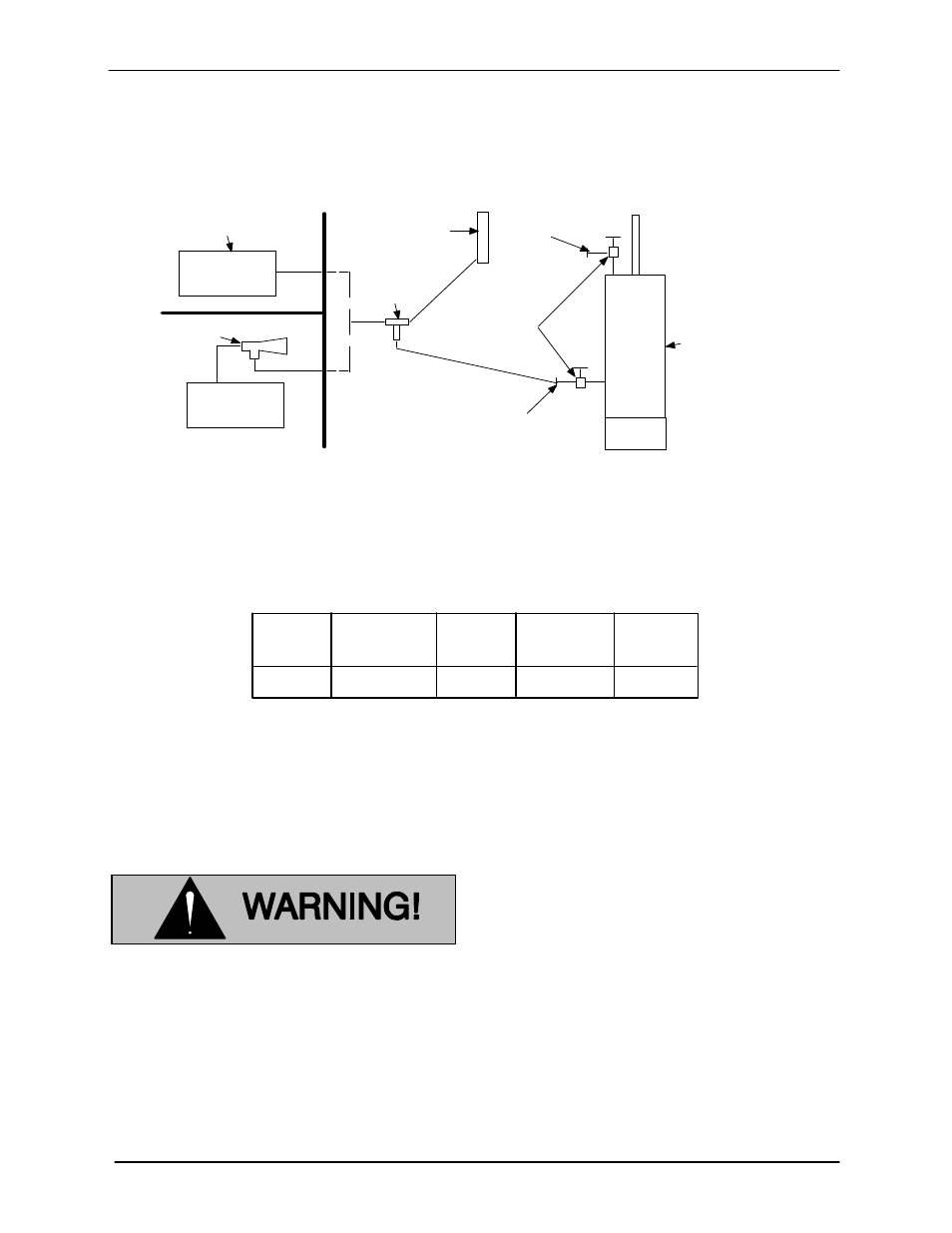

Figure E-6 shows a simple schematic for setting

up either a vacuum pump or a venturi/compressor

test system.

ООО

ООО

Tee

Manometer

Vacuum Pump

Submersible

Pump

Full-Closing

Ball-Type

Shutoff Valve

Quick Disconnect

Fitting

Quick Disconnect

Fitting

Air Compressor

Venturi

Figure E-6. Vacuum Test System

Table E-1 shows the vacuum to be drawn on each

cavity, and the duration to maintain each vacuum

reading. Any change in vacuum reading during

the test indicates a leak which must be identified

and corrected before putting the pump back into

service.

Table E-1. Vacuum Test Data

Pump

Model

Seal Cavity

Vacuum

(In. Hg.)

Motor Cavity

Vacuum

(In. Hg.)

Duration

(Minutes)

Duration

(Minutes)

S6B

30

8

20

2

LUBRICATION

Seal Cavity

Check the oil level in the seal cavity before initial

startup, after the first two weeks of operation, and

every month thereafter.

Check the oil level only when the pump

is cool. If the oil level plug is removed

when the pump is hot, pressure in the

seal cavity can cause hot oil to be

ejected as the plug is removed.

To check the seal cavity oil, lay the pump on its side

and remove the seal cavity plug (13) in the interme

diate. Tip the pump and drain off a small amount of

oil into a transparent cup. If the oil level is abnor

mally low, or the color milky or dark, refer to Drain

ing Oil From Seal Cavity in this section for instruc

tions and troubleshooting tips. If the oil is clear, ap

ply `Loctite Pipe Sealant With Teflon No. 592' or

equivalent to the threads of the pipe plug, before

reinstalling the plug.

To fill the seal cavity, remove the pipe plug (15) and

add the recommended grade of submersible

pump oil. Apply `Loctite Pipe Sealant With Teflon

No. 592' or equivalent to the threads of the pipe

plug, before reinstalling the plug.

See Table E-2 for quantity of lubricant when lubri

cating a dry (overhauled) pump. See Table E-3 for

lubricant specifications.

The grade of lubricant used is critical to the opera

tion of this pump. Use premium quality hydraulic oil

as specified in the following table. Oil must be

stored in a clean, tightly closed container in a rea

sonably dry environment.