Gorman-Rupp Pumps S6A1-E60 460/3 1401314 and up User Manual

Page 45

OM-06111

S SERIES PUMPS

PAGE E - 19

MAINTENANCE AND REPAIR

NOTE

Clean the cable leads and terminal plate in the ar

eas to be sealed with cleaning solvent. Incomplete

sealing will occur if the surfaces are dirt, oil or

grease coated.

Assemble the terminal posts (14), dyna seal wash

ers (16 ), and terminal collars (12) to the terminal

plate as shown in Figure E-2.

NOTE

Both the power cable and motor conductor leads

should be tinned prior to reassembly.

Slide a length of heat‐shrink tubing (10) up over

each of the power cable leads. Insert the leads in

the terminal collars and secure them using the al

len head setscrews (11). Slide the tubing down

each lead until the terminals are covered, and the

tubing contacts the terminal plate. The tubing

must extend up the leads far enough to ensure a

good seal.

Carefully heat each tube with a commercially avail

able hot air gun capable of producing 750

_F

(399

_C), and shrink the tubes around the cable

leads and terminal collars.

Use only Dow‐Corning 737 Silicone Adhe

sive (see the Parts List Manual for the part

number) or potting compound for sealing

terminal housing connections. Use of un

approved sealing products will void the

pump warranty.

NOTE

Do not use a mold or reservoir with the silicone

adhesive.

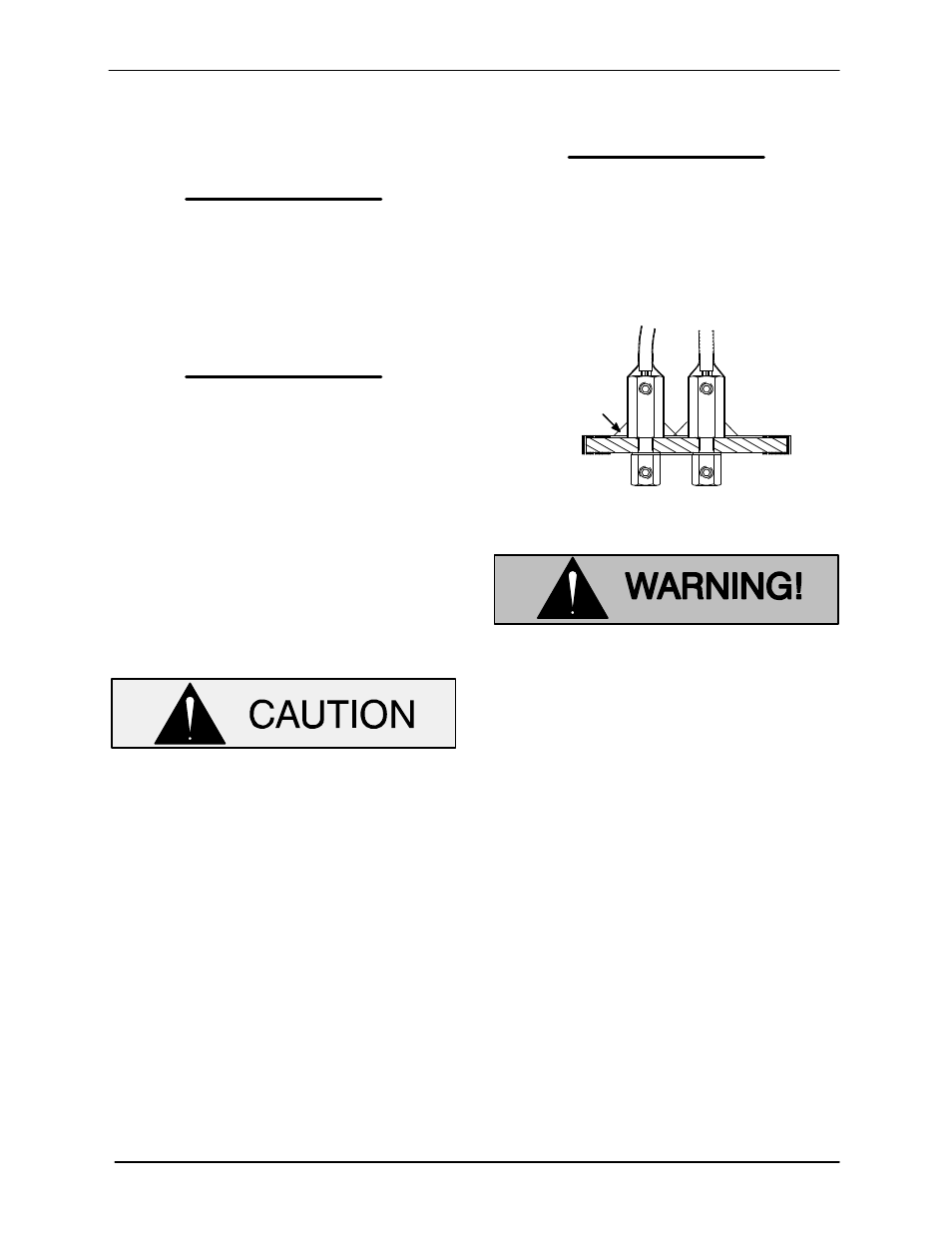

See Figure E-6 and check terminal locations. Ap

ply a 1/4 to 3/8 in. (6,4 to 9,7 mm) thick layer (maxi

mum) of silicone adhesive around each of the ter

minal posts as shown in Figure E-5. Remove any

adhesive from gasketed surfaces.

Silicone Sealant

Figure E-5. Silicone Adhesive Sealing

All air pockets, voids or gaps in the sili

cone sealant must be removed to en

sure a water‐tight seal in the terminal

housing. Otherwise, moisture entering

the terminal housing could cause a

short circuit, resulting in pump damage

and possible serious injury or death to

personnel.

Allow the adhesive to cure for at least one hour be

fore securing the terminal housing to the motor

housing.