Gorman-Rupp Pumps PA6C60-4045T 1481445 thru 1254713 User Manual

Page 42

PA SERIES

OM-06199

MAINTENANCE & REPAIR

PAGE E - 22

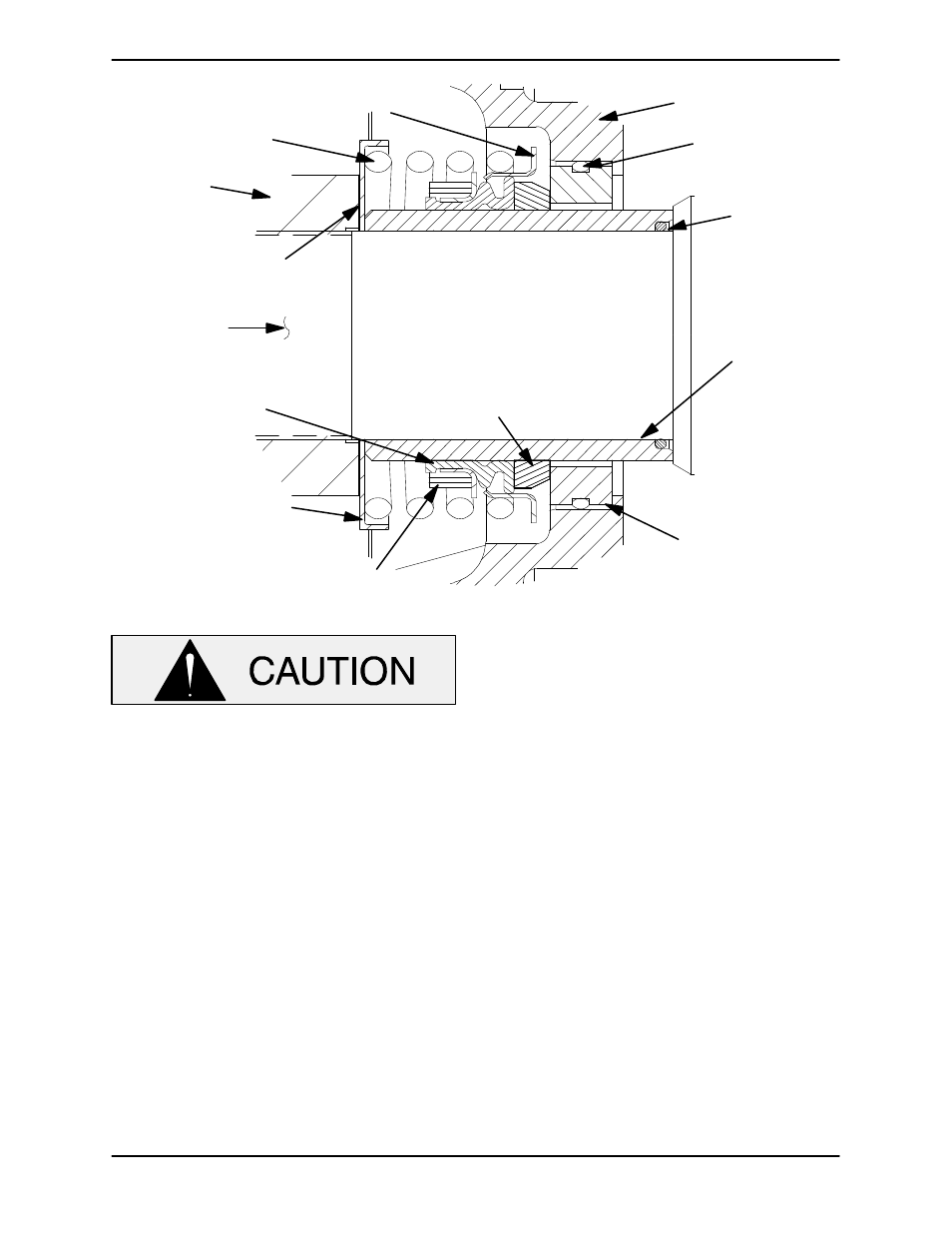

SEAL PLATE

O‐RINGS

IMPELLER

SHAFT

STATIONARY

SEAT

ROTATING

ELEMENT

DRIVE BAND

BELLOWS

IMPELLER

SHIMS

IMPELLER

SPRING

RETAINER

INTEGRAL

SHAFT

SLEEVE

SLEEVE

O‐RING

SPRING

CENTERING

WASHER

Figure 10. Seal Assembly

This seal is not designed for operation at

temperatures above 160

_

F (71

_

C). Do not

use at higher operating temperatures.

Lubricate the stationary seat O‐ring with water or

light oil. Press the stationary seat into the seal plate

(3) until fully seated.

Position the seal plate over the shaft and secure it

to the bearing housing (6) with the hardware (11

and 12). Be careful not to damage the stationary

seat on the shaft threads.

Lubricate a new seal plate O‐ring (30) with grease

and install it in the groove in the seal plate.

To prevent damaging the shaft sleeve O‐ring (28)

on the shaft threads, stretch the O‐ring over a piece

of tubing 1‐1/4 I.D. x 1‐1/2 O.D. x 2‐inches long (32

mm x 38 mm x 51 mm). Slide the tube over the shaft

threads, then slide the O‐ring off the tube and onto

the shaft. Remove the tube, and continue to slide

the O‐ring down the shaft until it seats against the

shaft shoulder.

Lubricate the shaft sleeve (24) with a small amount

of light oil and slide the rotating subassembly (con

sisting of rotating element, bellows and retainer),

onto the sleeve until the rotating element is just

flush with the undercut end of the sleeve.

Slide the shaft sleeve and subassembled seal onto

the shaft until the seal faces contact. Continue to

push the sleeve through the seal until the undercut

end seats over the O‐ring and against the shaft

shoulder.

Install the seal spring and spring centering washer.

Lubricate the seal as indicated in LUBRICATION

after the impeller is installed.

Impeller Installation And Adjustment

(Figure 5)

Inspect the impeller (1) and replace it if cracked or

badly worn.