Gorman-Rupp Pumps PA6C60C-F4L 1504811 and up User Manual

Page 46

PA SERIES

OM-05768

MAINTENANCE & REPAIR

PAGE E - 24

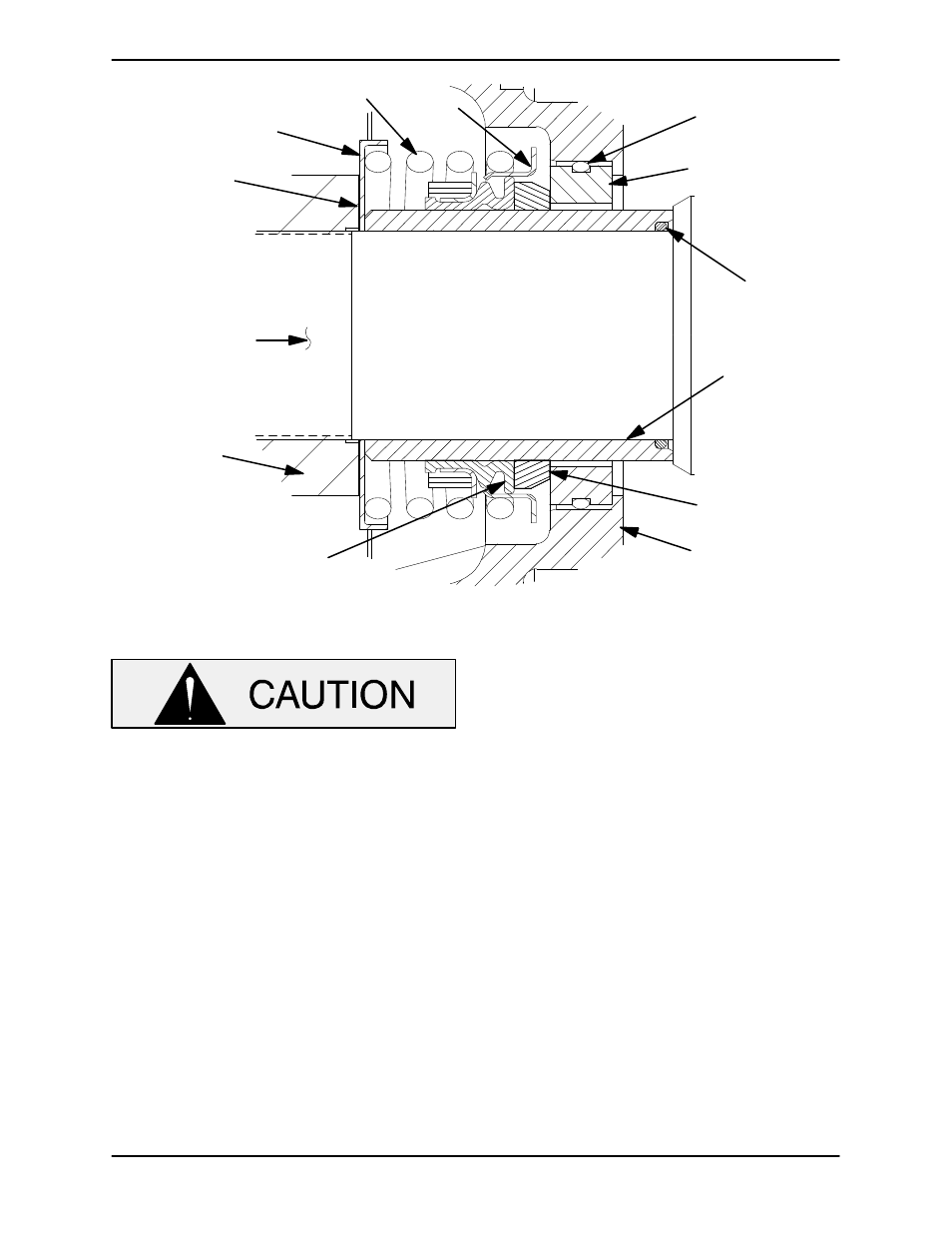

IMPELLER

SHAFT

IMPELLER

SHIMS

O‐RING

IMPELLER

SPRING

CENTERING

WASHER

SPRING

RETAINER

SHAFT

SLEEVE

STATIONARY

SEAT

BELLOWS

SEAL PLATE

SHAFT

SLEEVE

O‐RING

ROTATING

ELEMENT

Figure 11. Seal Assembly

This seal is not designed for operation at

temperatures above 160

_F (71_C). Do not

use at higher operating temperatures.

Lubricate the stationary seat O‐ring with water or

light oil. Press the stationary seat into the seal plate

(20) until fully seated.

Position the seal plate over the shaft and secure it

to the bearing housing (4) with the hardware (18

and 19). Be careful not to damage the stationary

seat on the shaft threads.

Lubricate a new seal plate O‐ring (35) with grease

and install it in the groove in the seal plate.

To prevent damaging the shaft sleeve O‐ring (27)

on the shaft threads, stretch the O‐ring over a piece

of tubing. The I.D. of the tubing must be slightly

larger than the O.D. of the shaft. To ease installation

the tubing wall should be as thin as possible. The

length should be long enough to cover the threads

on the end of the shaft. Slide the tube over the shaft

threads, then slide the O‐ring off the tube and onto

the shaft. Remove the tube, and continue to slide

the O‐ring down the shaft until it seats against the

shaft shoulder.

Lubricate the O.D. of the seal sleeve with a small

amount of light oil. Slide the rotating subassembly

(consisting of rotating element, bellows and re

tainer) onto the shaft sleeve (29) until the sealing

face is just flush with the undercut end of the

sleeve.

Slide the assembled shaft sleeve and rotating por

tion of the seal onto the shaft until the seal faces

contact. Continue to press the sleeve onto the

shaft until it is fully seated against the shaft shoul

der.

Install the seal spring and centering washer. Lubri

cate the seal as indicated in LUBRICATION after

the impeller is installed.