Gorman-Rupp Pumps PAV3C60C-B-E10 575/3 All serial numbers User Manual

Page 42

OM-06502

PA SERIES

MAINTENANCE & REPAIR

PAGE E - 15

cient capacity and that they are posi

tioned so that loads will be balanced

and the pump or components will not be

damaged when lifting. Suction and dis

charge hoses and piping must be re

moved from the pump before lifting. Lift

the pump or component only as high as

necessary and keep personnel away

from suspended objects.

Use only replacement parts provided or

approved by Gorman‐Rupp. Use of non‐

authorized parts may result in damage to

the equipment and/or injury to personnel

and will invalidate the warranty.

Priming Valve Removal And Disassembly

(Figure 3)

Liquid within the priming hopper may be

pressurized. When draining liquid from the

priming hopper, use caution to avoid con

tact with the liquid. Otherwise, injury to ser

vice personnel may occur.

Disconnect the air discharge tubing (37) from the

priming valve (9). Liquid will remain in the priming

valve. To drain the liquid, slowly remove the pipe

plug (not shown) in the valve body.

If draining is slow or difficult, the orifice in the valve

may be clogged (valve requires service).

Remove the hardware (32 and 33) and separate

the priming valve and hopper cap (7) from the suc

tion spool (4). Remove the gasket (5) and strainer

(6) from the suction spool and clean the strainer as

necessary.

It is not necessary to separate the priming valve

from the hopper cap unless complete replacement

of the priming valve is required. If replacement is

required, unscrew the priming valve from the nip

ple (8).

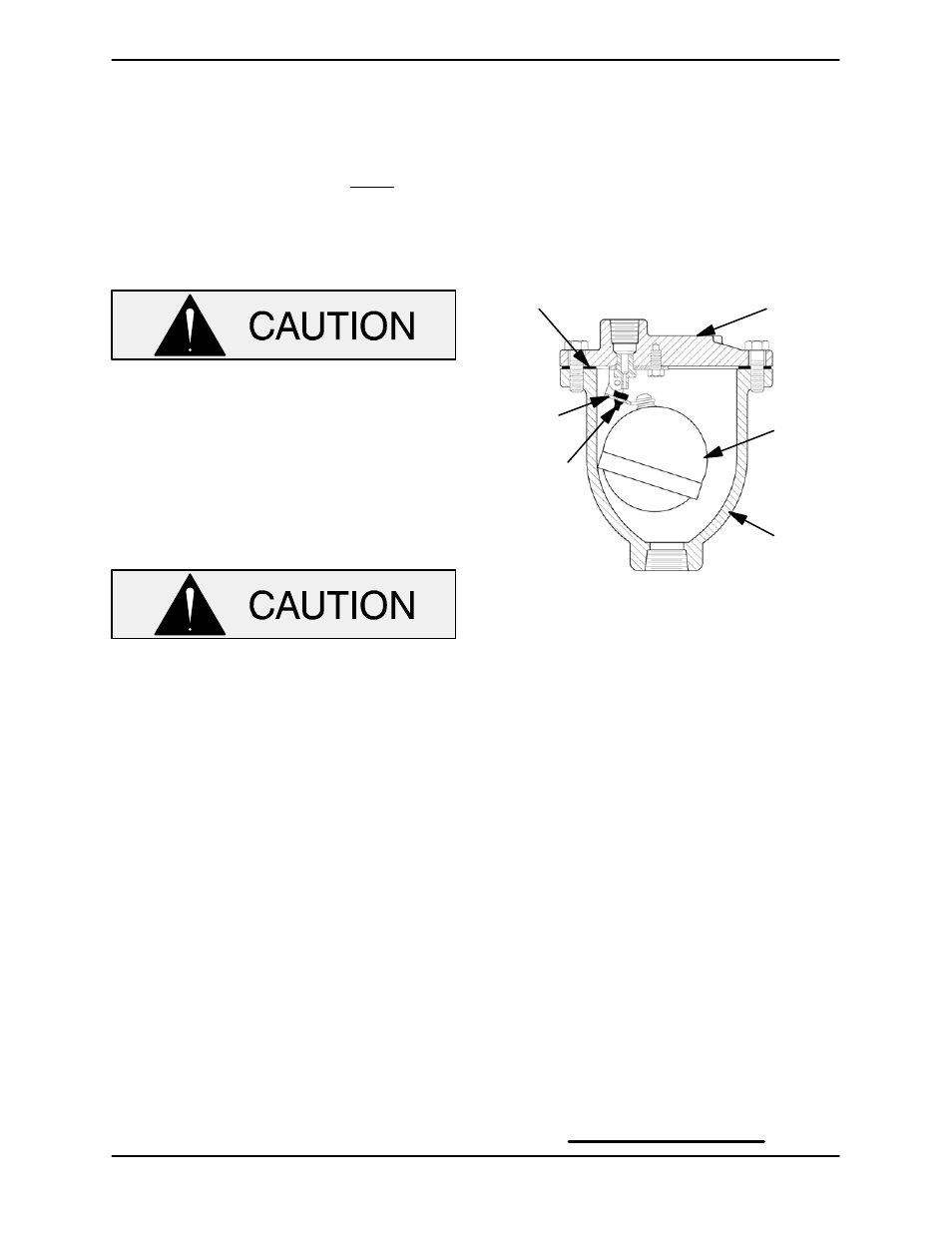

(Figure 7)

Remove the hardware securing the priming valve

cover to the priming valve body. Carefully lift the

valve cover and components from the priming

valve. Remove the priming valve gasket and clean

the mating surfaces.

If the priming valve float is stuck, it can usually be

cleaned without further disassembly.

Cover

Body

Gasket

Orifice

Button

Float

Float

Arm

Figure 7. Priming Valve

If excessive liquid continues to bypass through the

priming valve after the pump is fully primed, the ori

fice button may require replacement. Remove the

old orifice button from the hole in float arm and

install a new one.

Flap Valve Removal

(Figure 3)

Remove the discharge piping from the discharge

elbow (29).

Disengage the hardware (32 and 33) and remove

the discharge elbow (it may be necessary to tap on

the flange (25) with a soft‐faced mallet in order to

separate the discharge elbow from the flange).

With the discharge elbow removed, remove the

gasket (28). Unscrew the pin (26) from the flange.

Lift the flap valve assembly (27) out of the flange.

NOTE

Further disassembly of the flap valve is not required

since it must be replaced as a complete unit. Indi

vidual parts are not sold separately.