Gorman-Rupp Pumps PAV3B60C-3TNV70 1433753 and up User Manual

Page 37

OM-06260

PA SERIES

MAINTENANCE & REPAIR

PAGE E - 19

plate over the shaft and secure it to the bearing

housing with the flat head capscrews (4).

To prevent damaging the shaft sleeve O‐ring (36)

on the shaft threads, stretch the O‐ring over a piece

of tubing. The I.D. of the tubing must be slightly

larger than the O.D. of the shaft. To ease installation

the tubing wall should be as thin as possible. The

length should be long enough to cover the threads

on the end of the shaft. Slide the tube over the shaft

threads, then slide the O‐ring off the tube and onto

the shaft. Remove the tube, and continue to slide

the O‐ring down the shaft until it seats against the

shaft shoulder.

Lubricate the external stationary seat O‐ring with

light oil. Slide the seal assembly onto the shaft until

the external stationary seat O‐ring engages the

bore in the seal plate.

Clean and inspect the impeller as described in Im

peller Installation and Adjustment. Install the set

of impeller shims (3) provided with the seal and

install the impeller key (30) in the shaft keyway.

Position the impeller keyway over the impeller key

and press the impeller onto the shaft until it is

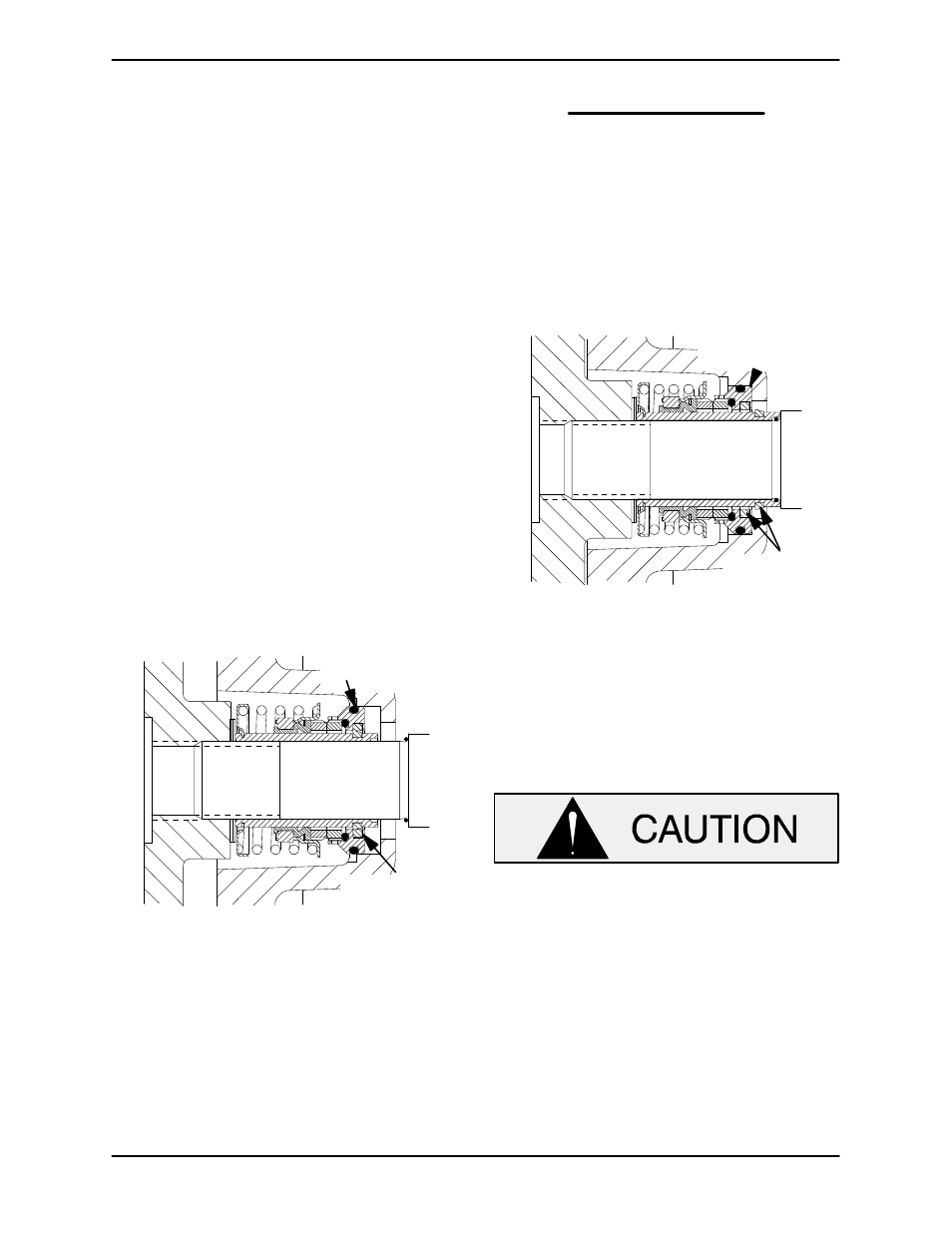

seated against the seal (see Figure 9).

O‐RING ENGAGED

WITH SEAL PLATE

BORE

SHEAR RING

(UNSHEARED)

Figure 9. Seal Partially Installed

Install the impeller washer (33). Apply a small

amount of `Never‐Seez' or equivalent anti‐lock

compound on the threads of the impeller screw

(32) and use the impeller screw to press the impel

ler onto the shaft. This action will press the station

ary seat into the seal plate bore.

NOTE

A firm resistance will be felt as the impeller presses

the stationary seat into the seal plate bore.

As the stationary seat becomes fully seated, the

seal spring compresses, and the shaft sleeve will

break the nylon shear ring. This allows the sleeve

to slide down the shaft until seated against the

shaft shoulder. Continue to use the impeller screw

to press the impeller onto the shaft until the impel

ler, shims, and sleeve are fully seated against the

shaft shoulder (see Figure 10).

STATIONARY SEAT

FULLY SEATED IN

SEAL PLATE BORE

SHEAR RING

(SHEARED)

Figure 10. Seal Fully Installed

Torque the impeller screw to 90 ft. lbs. (12,4 m.

kg.).

If necessary to reuse an old seal in an emer

gency, carefully separate the rotating and station

ary seal faces from the bellows retainer and sta

tionary seat.

A new seal assembly should be installed

any time the old seal is removed from the

pump. Wear patterns on the finished faces

cannot be realigned during reassembly.

Reusing an old seal could result in prema

ture failure.

Handle the seal parts with extreme care to prevent

damage. Be careful not to contaminate precision

finished faces; even fingerprints on the faces can

shorten seal life. If necessary, clean the faces with a

non‐oil based solvent and a clean, lint‐free tissue.

Wipe lightly in a concentric pattern to avoid

scratching the faces.