Gorman-Rupp Pumps PAV3B60C-3TNV70 1433753 and up User Manual

Page 35

OM-06260

PA SERIES

MAINTENANCE & REPAIR

PAGE E - 17

race, balls, or ball cage. Press only on the

inner race.

Secure the outboard bearing to the shaft with the

snap ring (27)

When installing the shaft and bearings into

the bearing bore, push against the outer

race. Never hit the balls or ball cage.

Slide the shaft and assembled bearings into the

bearing housing until the retaining ring on the out

board bearing seats against the bearing housing.

Apply a light coating of oil to the lip of the oil seal (7)

and press it into the mounting flange (25) with the

lip positioned as shown in Figure 3. The face of the

oil seal should be flush with the chamfer on the

mounting flange bore.

Install the mounting flange gasket (26) and secure

the mounting flange to the bearing housing with

the hardware (9 and 24). Be careful not to damage

the lip of the oil seal on the shaft keyway. Torque the

capscrews (24) to 41 ft. lbs. (5,6 m. kg.).

Apply a light coating of oil to the lip of the oil seals

(7A and 7B) and press them into the lip seal holder

(10) with the lips positioned as shown in Figure 3.

Slide the assembled lip seal holder and lip seals

over the shaft, using caution not to roll the lip of the

inboard oil seal on the shaft shoulder. Secure the

lip seal holder to the bearing housing with the hard

ware (8 and 9).

Lubricate the bearings as indicated in LUBRICA

TION at the end of this section.

Securing Drive Assembly and Bearing Housing

to Engine

(Figure 2)

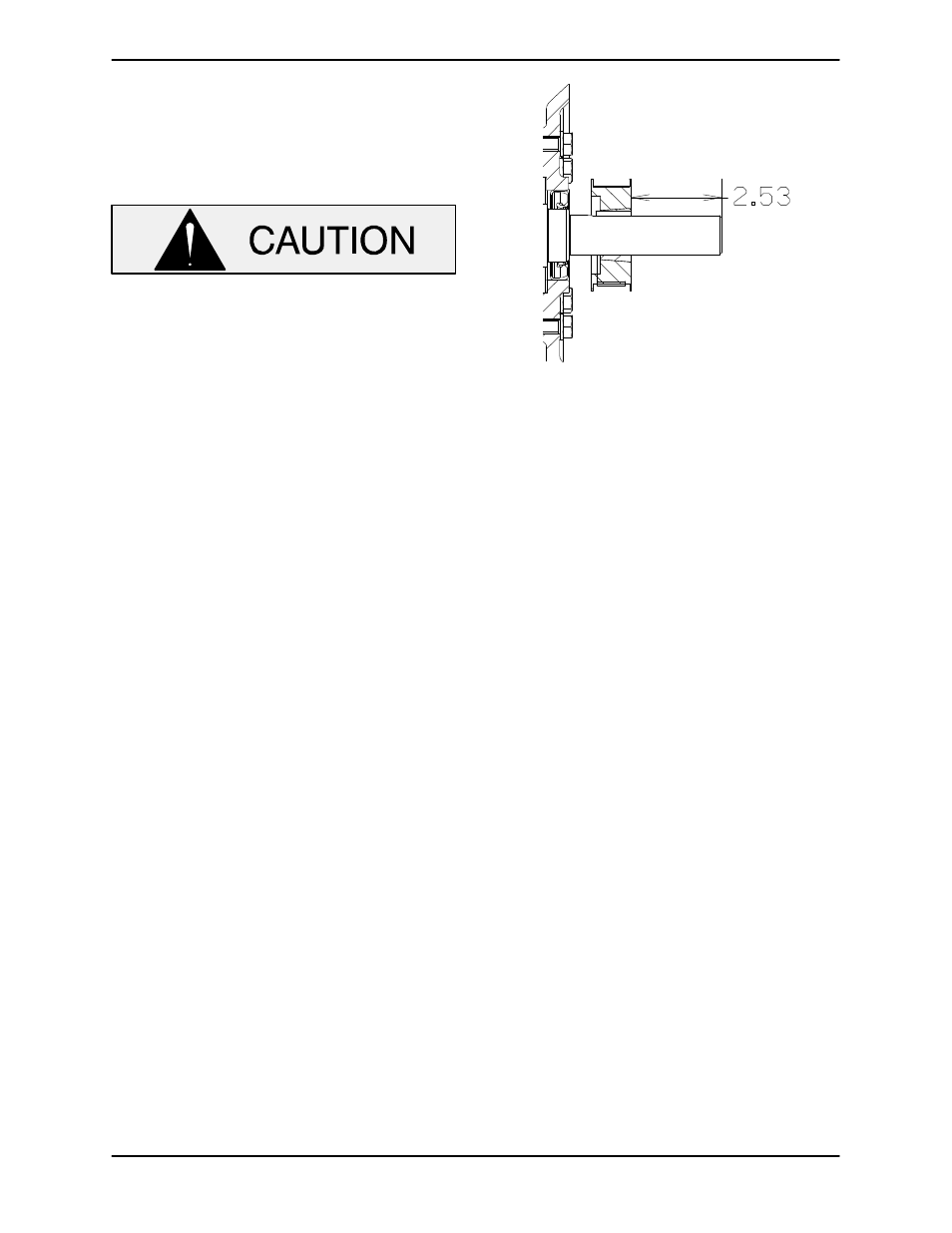

Install the key (49) in the shaft keyway, making sure

to leave room in the keyway for the drive key (46).

Install the sprocket (47) and bushing (48) on the

shaft to the dimension shown in Figure 7.

Figure 7. Drive Sprocket Positioning

Secure the bushing and sprocket to the shaft by

torqueing the bushing screws to (55 in. lbs. or 6,3

m. kg.). Install the belt (27) over the sprocket and

up through the slot in the mounting flange (25, Fig

ure 2).

Install the shaft key (46) in the shaft keyway. Posi

tion the inner hub of the coupling assembly (43) on

the shaft with the hub setscrew toward the drive

end of the shaft. The end of the hub should be just

flush with the end of the shaft. Torque the hub set

screw to 7 ft. lbs. (1 m. kg.).

Align the keyway in the bushing (2) with the shaft

key, and slide it onto the shaft until the face of the

bushing is just flush with the end of the shaft. Ro

tate the flexible portion of the coupling until the

tapped holes for the two setscrews align with those

in the bushing, and install the setscrews.

If the flexible portion of the coupling was separated

from the engine flywheel for replacement, secure

the new coupling to the flywheel with the hardware

(44 and 45). Torque the capscrews to 18 ft. lbs. (2,5

m. kg.).

Using a suitable lifting device, position the as

sembled drive and rotating assembly so the hub of

the coupling seats inside the flexible outer ring at

tached to the engine flywheel.

Use a suitable hoist and sling to position the air

compressor assembly (26) on the mounting flange

(25, Figure 2). Slide the belt (27) over the air com

pressor sprocket (18, Figure 3). Use a pry bar to

raise the compressor high enough to install the

spacers (38) between the compressor and the

mounting flange. Secure the compressor to the

mounting flange with the hardware (12 and 29).