Gorman-Rupp Pumps PAV3A60C-B 1511107 and up User Manual

Page 35

OM-06525

PA SERIES

MAINTENANCE & REPAIR

PAGE E - 15

inboard oil seal on the shaft shoulder. Secure the

lip seal holder to the bearing housing with the hard

ware (8 and 12).

Lubricate the bearings as indicated in LUBRICA

TION at the end of this section.

Securing Rotating Assembly to Driver

(Figures 1, 2 and 3)

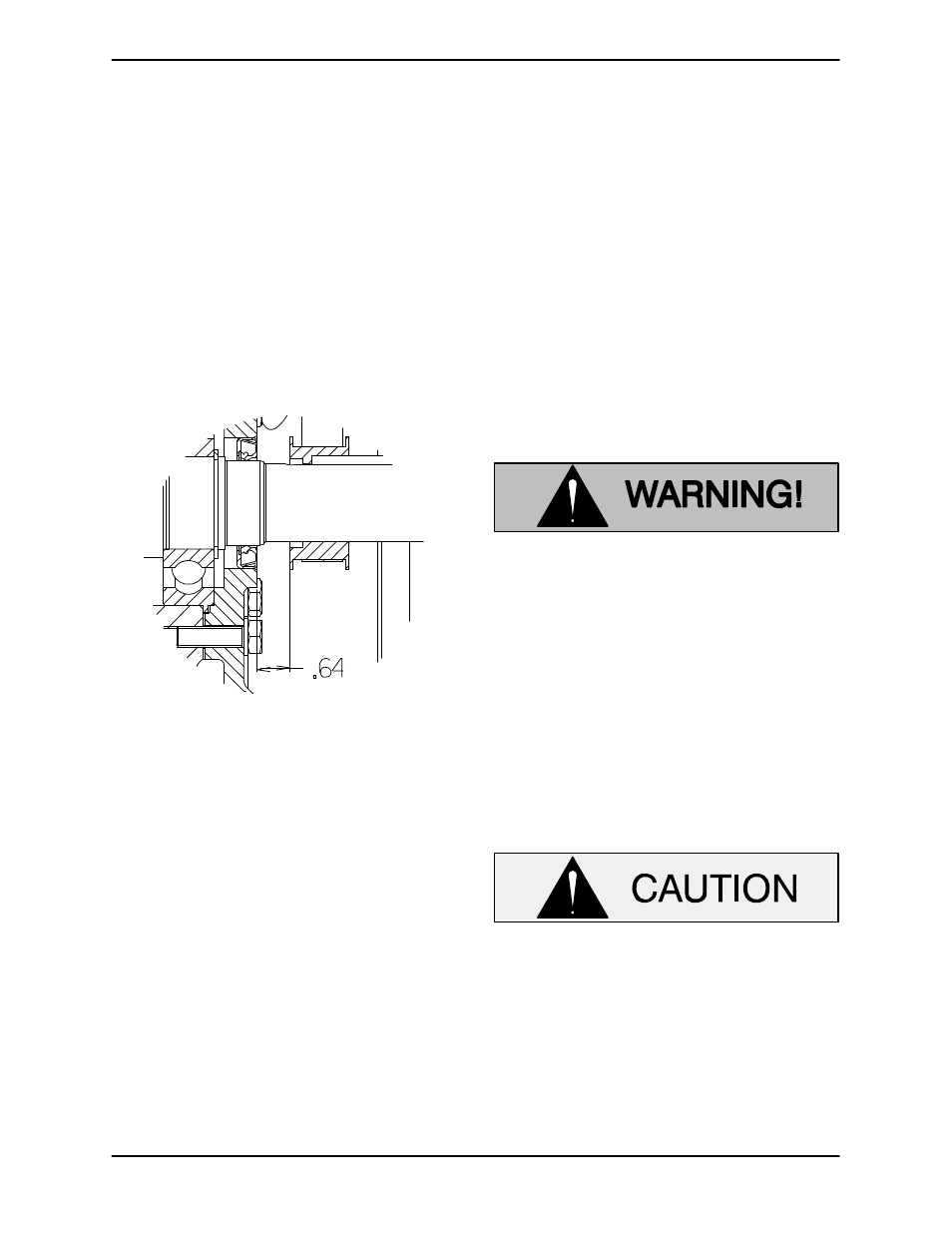

See Figure 3 and install the key (34) in the shaft

keyway, making sure to leave room in the keyway

for the drive key (35). Install the sprocket (43, Fig

ure 2) and bushing (44, Figure 2) on the shaft to the

dimension shown in Figure 6.

Figure 6. Drive Sprocket Positioning

Secure the bushing and sprocket to the shaft by

torqueing the bushing screws to (55 in. lbs. or 6,3

m. kg.). Install the belt (27) over the sprocket and

up through the slot in the mounting flange (25, Fig

ure 3).

Install the drive key (35, Figure 3) in the shaft key

way.

Using a suitable lifting device, position the rotating

assembly on the base and secure the flange to the

support (50, Figure 1) with the previously removed

hardware. Reinstall and align the coupling.

Installing Air Compressor Assembly

(Figure 2)

Use a suitable hoist and sling to position the air

compressor assembly (26) on the mounting flange

(25, Figure 3). Slide the belt (27) over the air com

pressor sprocket (43). Use a pry bar to raise the

compressor high enough to install the spacers (42)

between the compressor and the mounting flange.

Secure the compressor to the mounting flange

with the hardware (10 and 30).

Reinstall the U‐bolt and hardware (31, 32 and 33).

Install the coupling guard (28) and secure it with

the previously removed hardware (10 and 29).

Seal and Impeller Installation

(Figures 3, 7, 8 and 9)

Most cleaning solvents are toxic and

flammable. Use them only in a well ven

tilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solvent contain

ers.

Clean the seal cavity and shaft with a cloth soaked

in fresh cleaning solvent. Inspect the stationary

seat bore in the seal plate for dirt, nicks and burrs,

and remove any that exist. The stationary seat bore

must be completely clean before installing the

seal.

A new seal assembly should be installed

any time the old seal is removed from the

pump. Wear patterns on the finished faces

cannot be realigned during reassembly.

Reusing an old seal could result in prema

ture failure.

To ease installation of the seal, lubricate the shaft

sleeve O‐ring and the external stationary seat O‐

ring with a very small amount of light lubricating oil.

See Figure 7 for seal part identification.